This application note was provided by our valued suppliers FUTEK.

Application Summary of High Performance Racing Car Suspension Tests

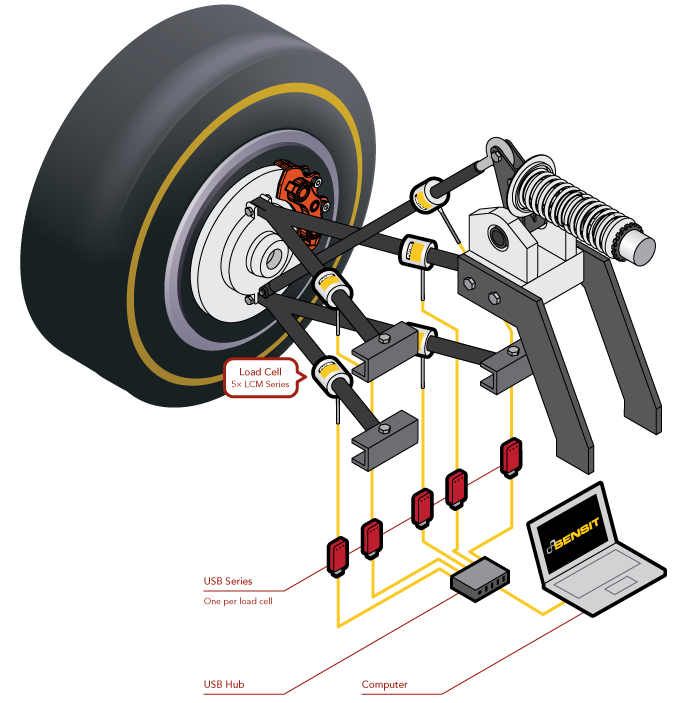

In a racing vehicle, the high performance suspension system does more than hold the car up. Firstly, it adapts to the aerodynamic forces on the vehicle, varying road conditions, and driver inputs. In addition, complex multipoint suspension systems in use in NASCAR® and Formula 1® require the use of modelling and simulation. Secondly, this is to ensure compliance under load. Modeling and analysis undertaken. To account for those variables.

The final step to maximise performance is live testing to validate the simulation model. Therefore, providing detailed information of the load running through each arm, accurate steering load measurements, and indirect front tire grip enabling adjustments of the suspension system to optimise performance and handling.

Products in Use

- LCM Series Miniature In Line Load Cells or

- LCB Series Fatigue Rated Rod End Tension

However, the Compression Load Cells paired with a USB220 USB Output Module

How it works

- LCM Series or LCB Series load cells are threaded in-line with each suspension arm. It is critical to study the load path and avoid any side load and/or moments.

- As the vehicle is operated on a test stand or driven, the output signal is sent to the USB220 units.

- The USB220 displays and logs the data to a PC via our SENSIT™ software. In conclusion, this data can be used to validate and fine-tune the performance of the suspension system.

Please note the drawings are purely conceptual. Finally, should you require more information on this application, contact us.