Industry Leaders in Purpose-Built Technology & Embedded Systems for Industrial & Extreme Environments.

Intelligent design, performance & engineering.

Metromatics PTY LTD

Our industry-leading solutions withstand the most extreme environments. They also provide predictive analytics for industrial and rugged applications.

Thanks to our ongoing relationships with high quality electronic suppliers; we provide you with high-end, built-for-purpose embedded solutions that always perform at their best to keep you running.

Our knowledge and experienced staff will provide you with an in-depth working relationship to deliver a solution that meets your requirements within scope and budget.

Our Customers

Industries

Providing Automotive Test, Sensors and Monitoring Equipment.

Custom Engineered to exceed your requirements.

Custom Engineered to exceed your requirements.

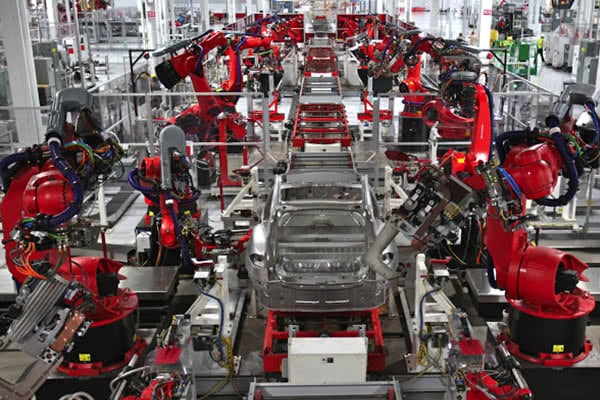

Delivering all your manufacturing needs.

Providing Remote Monitoring Wireless Sensors & Miniature Surgical Sensor Products to the Medical Industry.

Proven. Reliable. Leading Edge. Rugged. Intelligent. Supported. Ahead of the Rest.

Tools for Power Quality Management or Power Conversion.

Display, Monitoring and Analysis Solutions to the Public Transport Industry.

Measurement and Analysis Tools for your water and wastewater applications.

Our ENgineering Services

Metromatics News & Events

Metromatics current news and events highlight the latest product and application information from ourselves and our trusted partners.

Why Choose Metromatics’ 19-Inch MIL-STD Comms Racks

Metromatics proudly designs and manufactures specialised 19-inch Comms Racks, which are …

Seismic Assessment of an Existing Building

Elevate Your Engineering Expertise: Seismic Safety Assessments Unlocked In the fast-paced …

Dewesoft’s Power Analyzer: Global Certification Simplified for PV Inverters

Precision and reliability are non-negotiable in the power generation and distribution …

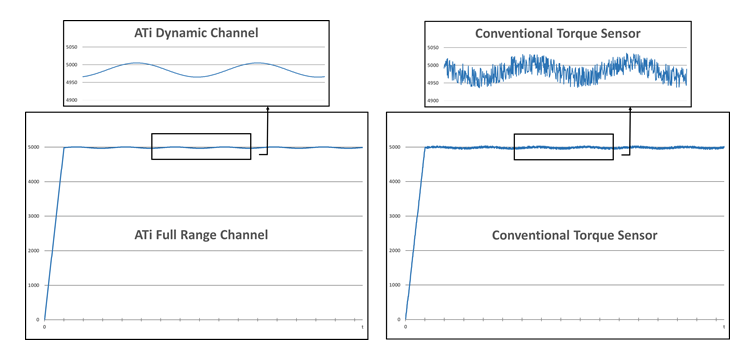

How to capture precise gear mesh torsional data

For manufacturers of axles and automotive powertrain components, a significant hurdle …

Ready to get more done? Take your team’s imagination and productivity to the next level with Metromatics.

Our Customers Include