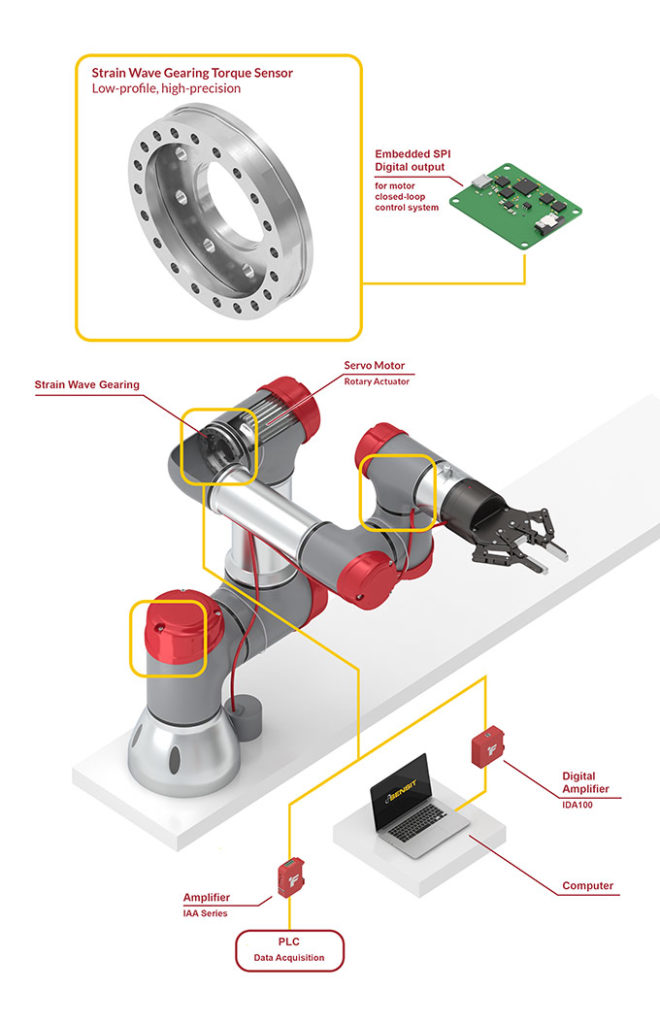

FUTEK have developed strain wave harmonic gearing torque sensors used in Surgical Robotic Arm applications. This application requires high precision and control, in order to improve the robot’s performance.

Illustrated in the image above. The strain wave gearing torque sensor is between the robot arm strain wave gearbox and its mounting points. Firstly, the torque sensor measures the torque outputted during arm movement. This is then amplified by the IAA Series, IDA100 amplifier or QIA Multi-Channel SPI Digital Output. Secondly, the amplified signal is sent either to the PLC or robotic arm controller. Which provides a high precision torque feedback and allows closed control loop system. Additionally, with the IDA100, amplified output from the sensor can be monitored. Plus, adjust the analogue functions digitally with FUTEK’s SENSIT™ Software.

Strain wave harmonic gearing torque sensor benefits in robotic arm applications:

- Reduces the inertia of the robot arm and improves dynamic performance through faster acceleration and faster settling time

- Offers high reduction ratios in a single stage and very low backlash

- Increases payload capacity

- Supports motion control with low power consumption

- Light-weight, low-profile, and high-precision capabilities for closed-loop feedback

- High flexibility in geometry and design

- Distributed over the robotic arm joints, therefore reducing the moment of inertia

It is an alternative to six-degrees-of-freedom sensors

Strain wave harmonic gearing sensors are an alternative solution to six-degrees-of-freedom( 6 DOF) sensors. Therefore, they are ideal for high-precision robotic arm applications, such as minimally invasive robotic surgery.

For example, during some laparoscopic surgery procedures, surgeons must hold the position of the end effector (the instrument inside the abdominal cavity) while the robot arm is moving. This manoeuvre is difficult to perform with 6 DOF sensors only. This is because it requires torque measurement on each joint. Used in order to calculate the direction and magnitude of the equivalent force based on the output of each joint torque.

Other benefits of using strain wave harmonic gearing sensor as an alternative to 6 DOF sensors:

- Lower cost to implement, as torque measurement is used for selected joints only

- Single-channel per joint substantially reduces the learning curve and hidden implementation costs

- Cheaper and easier to service and maintain – as one sensor is serviced or replaced without taking down other sensors

- Traditional cross-talk from 6 DOF solution is mostly eliminated

- Flexibility on custom geometry for embedded electronics (analog, SPI, etc.)

- Flexibility on electronics to embed fault detection and add redundancy

- Lightweight – Each joint torque sensor weighs approximately 30 grams (including cables), compared to ~400 grams of traditional 6 DoF F/T Sensors.

- High-temperature stability

- Great linearity and repeatability specifications

- More data available, better resolution from separate sensors at each joint

- Large aperture/hole/ID – easier to pass wiring and tools through

Finally, FUTEK’s torque engineering team has deep expertise in customising low-profile, high-precision strain wave harmonic gearing torque sensors for any robotic application that uses strain wave gear technology. For more information on these FUTEK products or this application, contact us.