This application note on Using Force Sensors for Battery Manufacturing has kindly been provided by our friends at FUTEK. To read the original article, click here.

There has been a shift in the energy matrix worldwide. The worldwide aim is to reduce the reliance on the fossil fuels and impact on the environment.

Due an increased interest in e-mobility, there has been a need for more lithium-ion battery solutions. Therefore, a greater requirement to build more efficient and high throughput EV batteries factories and production lines.

Did you know that FUTEK force and torque sensors are important components of these new technologies? Firstly, they are advanced measurement solutions and part of the entire battery process. They provide in-process inspection, battery manufacturing process closed loop force and torque control and mechanical testing for quality control.

Control and precision for battery production

In battery manufacturing, high yield and repeatability are just as important as cost-effective solutions. FUTEK’s extensive sensor portfolio allows process control engineers to develop automated solutions to most of the battery manufacturing processes.

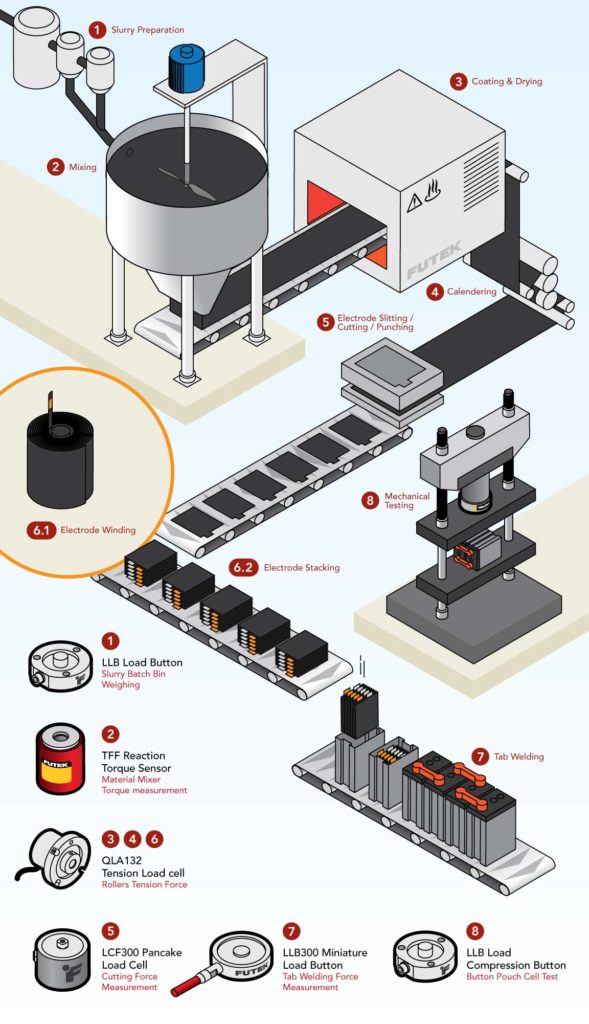

Let’s check out the process for battery manufacturing and see how FUTEK’s products are involved:

Slurry Preparation – Batch Bin Weighing

Firstly, battery cell raw materials are expensive. Plus they are more than 50% of the total production costs. Secondly, weighting the bin batch is an alternative to determining moisture content. It is a key to providing uniformity and traceability. FUTEK’s LLB Button Series used in manufacturing batch weighing applications. Installed at the base of each leg of the slurry container. These compression load buttons measure the contents of the container as it increases and decreases.

Slurry Mixing – Material Mixer Torque Measurement

Battery slurries are fluid matter. They contain a large percentage of solid particles of different chemicals, sizes and shapes. Therefore, measuring and controlling the slurry viscosity is key for the process stability, ease of mixing and coating performance which impacts the finished electrodes.

In order to determine, the thickness/glueyness and rheological property measurements of the slurry – a mixer with embedded rheometer is required. In this case, a rheometer with a rotational cylinder is used to measure slurry shear at various rotational velocities. Therefore a torque sensor is required to measure the torque generated as the slurry is med. A TFF series reaction torque sensor is mounted along the mixing agitator axle cylinder holding the slurry undergoing analysis by the viscometer.

Coating, Drying and Calendering – Belt Rollers Tension Control

Maintaining the correct level of tension on web materials is critical. This is to ensure the quality. Also, to minimise material breakage and other battery manufacturing process issues that can lead to unplanned downtime. Battery manufacturing machines require high quality tension control components. This ensures increased machine capabilities, wider operating ranges and much better process control. FUTEK’s QLA132 is a Custom Roller Tension Shear Force Load Cell. Used for both closed loop and open loop tension control.

Electrode Slitting/Punching – Cutting Force Measurement

After coating and calendaring, the battery electrodes are winded in a roll. Cut to desired shape and small dimensions of the cells. Slitting is a delicate process. Therefore the precise requirement for electrode width, edge flatness and burrs. The cut must be clean to avoid any cell malfunction. The LCF300 Pancake Load Cell is a miniature universal load cell. It is a low profile sensor that is accurate and fatigue resistant.

Tab Welding Force Measurement

Resistance welding used in battering manufacturing industry for nearly 40 years. However, the application of displacement electrode force measurement is relatively new. Also it allows manufacturers the ability to monitor and close loop feedback control tools. As well as enabling the fine tuning of the tab welding process to get high quality results. FUTEK’s LLB300 Load button is a force sensing device to provide force feedback to the tab welding automation system.

Pouch Cell Mechanical Testing

During charging and discharging, the cell pouches swell or expand. Through testing, the lithium-ion battery expands, and the LLB Compression Button Load Cell measures the force upon the end plates as the battery cell expands. Therefore, allowing the evaluation of the stress on the battery cells during the charge/discharge cycles. The LCF450 Pancake Load Cell is an alternative for Pouch Cell Mechanical Testing.