This application note on using Ethernet I/O to remotely monitor wind turbines has been kindly provided by our friends at Acromag. To see the original article, click here.

The Problem

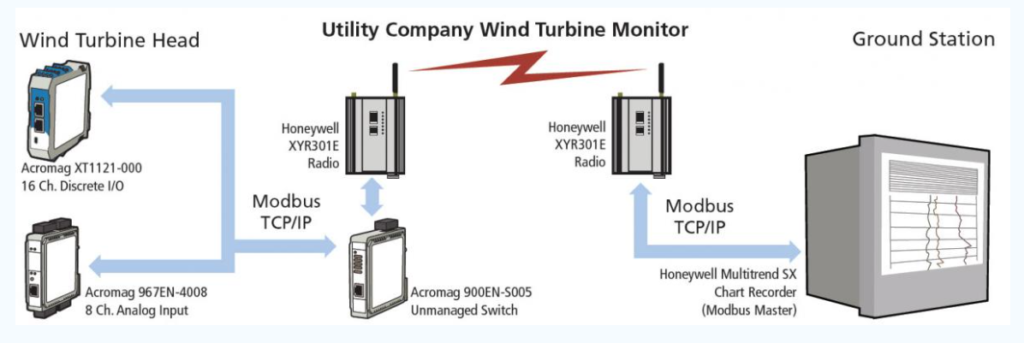

Firstly, a large utility company needs to monitor multiple data points on a wind turbine. However, the turbine head is nearly 100 Metres above the ground. The data must be sent to a ground station. It is then saved to a data logger and displayed on a Honeywell chart recorder. Secondly, the data will then be downloaded from a remote data collection site.

System Requirements

The wind turbine head has several collection points. Both discrete and analog data will be acquired and sent to the ground station using Modbus TCP/IP protocol. The Honeywell Chart Recorder is a Modbus client. The system will use Honeywell Ethernet radio links to send the information from the wind turbine head to the ground station. Thereby, eliminating long Ethernet cable runs.

Implementing the Ethernet I/O to remotely monitor wind turbines

- At the ground station, connect the Honeywell chart recorder to the Ethernet port of one of the Honeywell radio transceivers. Configure the radio transceiver as an access point. Set up the chart recorder as Modbus TCP/IP Client. Also configure the chart recorder to communicate to the XT1121-000 and 967EN-4008 Acromag Modbus Server Modules.

- At the turbine head, configure the radio transceiver as an access point. Then connect the Ethernet port to one of the ports on a 900EN-S005 unmanaged switch. Connect the XT1121-000 discrete I/O module and the 967EN-4008 Analog current input module to two of the other ports on the 900EN-S005 switch.

- Connect the discrete signals to the XT1121-000 inputs, and the analog current signals to the 967EN-4008 inputs.

Products Used:

XT1121-000 Modbus Discrete I/O Module

967EN-4008 Modbus Analog Current Input Module

900EN-S005 Unmanaged Ethernet Switch

So why use Acromag?

The utility company has used Acromag products in their power plant monitoring and control systems in the past. Therefore, they are familiar with the equipment and trust the accuracy and reliability.