This application note is on how Metromatics supplied a Wireless Tank Level Monitoring Solution for a Bitumen Emulsion Storage Tank in a remote part of Western Australia.

Our customer

Our customer is a leading provider of integrated services and asset management in Australia and New Zealand. They were contracted to design, supply and maintain road surfaces in a remote mining region in Western Australia. Part of their essential equipment for road repair/sealing was Bulk Bitumen Emulsion Storage tanks. These tanks are distributed on remote sites around the contract work area covering thousands of square kilometres.

About Bitumen Emulsion

Bitumen emulsion is difficult to deal with and store because it is a highly sticky material that is sensitive to temperature changes. It can also easily become unstable and separated if not stored and handled properly. It is also prone to contamination from other materials and can be difficult to clean up if spilled.

Problem:

Prior to the installation of our solution.

There was no automated tank level system in place.

- Manual Calculations + Consequences: Reliance was on personnel to roughly work out the amount of product used. Then to remember to write down this approximate figure. Thus, this led to occasions where the product ran out. Unfortunately, due to the remote location, product couldn’t be delivered immediately. Therefore, works would come to a stop and our customer would be forced to pay penalties for the contract.

- Climbing Tanks for Manual Measurement: Another issue was the Emulsion storage tanks stand at 6 Metres high. To get an accurate reading, staff were regularly required to climb the tank and measure the content levels with a manual dipstick. Even though all safety precautions and harnesses were worn, safety of the staff was number one priority and the ability to move away from this activity was encouraged.

With the capacity to get automatic, accurate bitumen emulsion levels and to remove the need for staff to work at heights, the StarPin wireless remote monitoring device paired with a PCR radar sensor became cost effective and attractive alternative.

Implementing the Wireless Tank Level Monitoring Bitumen Emulsion Solution:

The easy installation of the products to their Emulsion Tanks was conducted by our customer by following the installation manual.

Featured Products:

| Product | Features |

Using the CATM1 (LTE-M) Mobile network the StarPin transmits valuable tank level data directly to the LevelCon mobile secure cloud | 1 x StarPin Remote Monitoring Device – Wireless Communication via Mesh Network and Multi Carrier SIM Cards – Alarm Capabable for high / low levels via text or e-mail – Class I Div 1 Group D Certified – intriniscally safe – Integrated temperature + barometric pressure sensor – 24/7 access to data on LevelCon Cloud or local SCADA System – Solar Powered with supercapacitor – USB Power option – Supports wide range of sensors

|

The MicroTron PCR Radar uses Pulsed Coherent Radar sensing technology. It requires a 1.5“ NPT PVC Bushing for Tank Connection

| 1 x PCR Radar Sensor – ABS, PVC, PTFE Body – NPT PVC 1.5“ Process Connection – Mesh Network Connectivity – 5 Year Battery Expectancy* – Dual gasket housing seal – Easy calibration 0-full scale – Range 0.5 – 10 Metres – Not affected by Fumes, vapour, heavy build up + most temperature conditions. |

| 1 x 12-month Contract Data Plan This provides your data reports on the secure 24/7 LevelCon App. Available from Google Play or the App Store |

Plus your own tablet, ipad, iPhone or PC to view the app and access to the reports that your data creates on the LevelCon cloud.

Type of Information Produced:

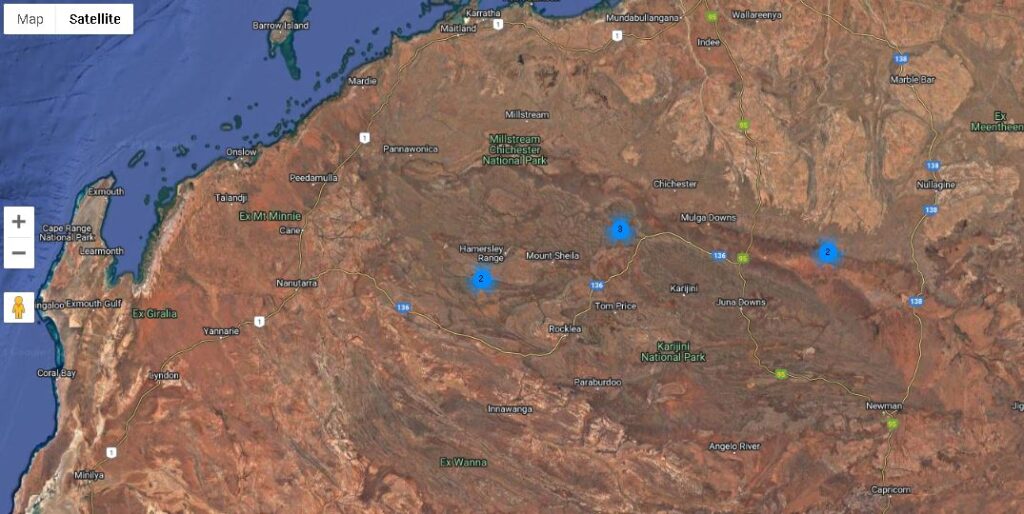

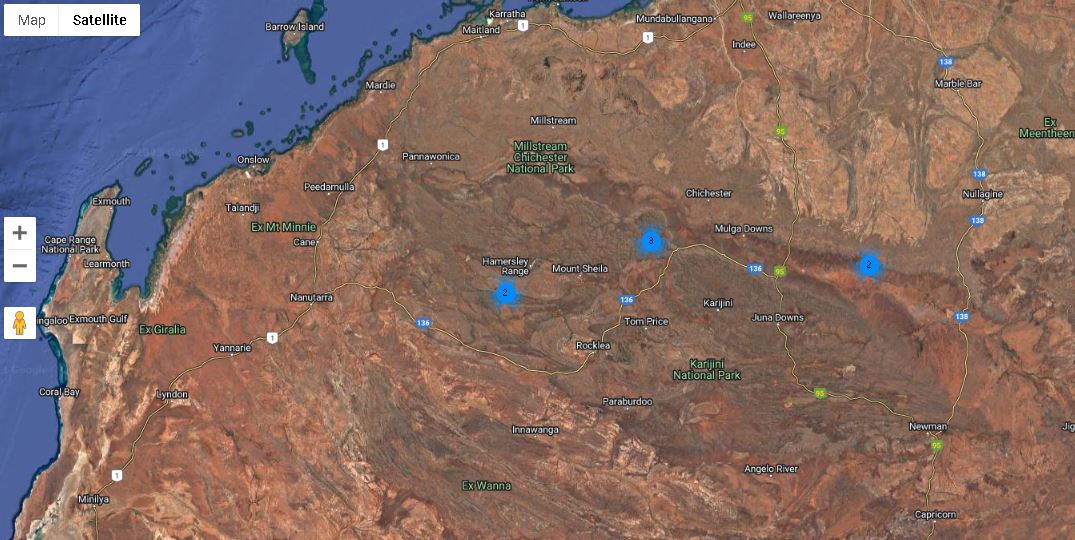

- Maps the location of the asset in standard and in satellite versions

Note the remoteness of the location. However, you can be in Perth or other areas and still track the levels of a specific tank or all models together.

2. Monitor and Report Current Levels.

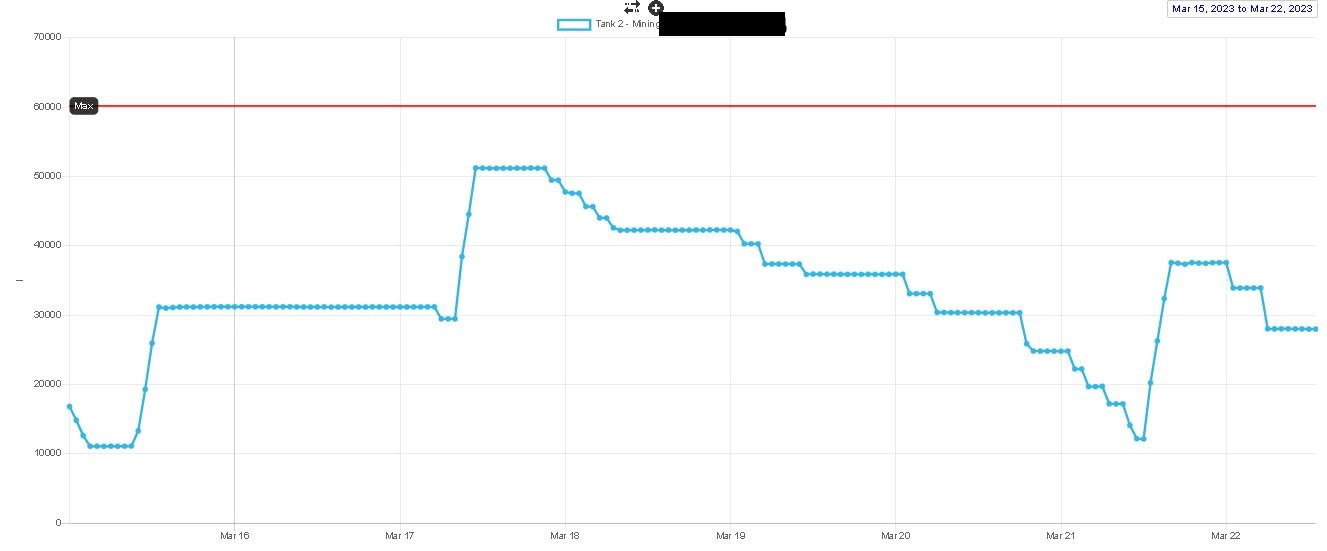

This report is set over a 7-day period. A maximum fill level has been set at 60,000 Litres. From the report we can determine when it was filled up and the amounts used over what period/day.

One advantage of the StarPin is the ability to set Maximum and Minimum Levels required – Then alarms by either text/e-mail can be set for significant level changes.

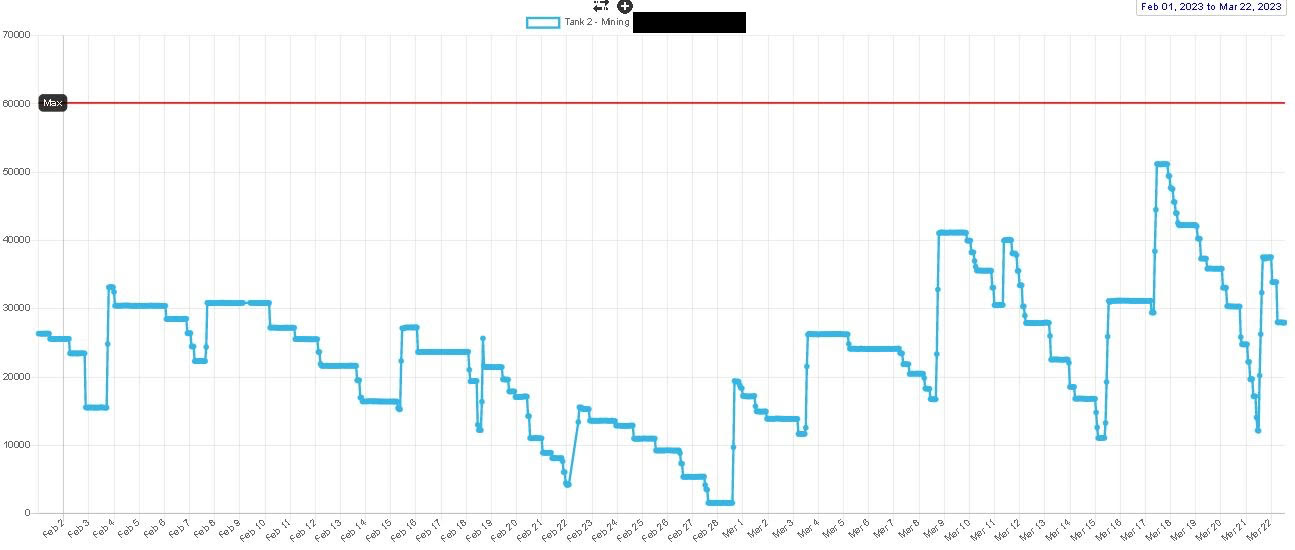

3. View trends of the tank levels

This report highlights the trends over a month. However, you can create reports to include up to the last 3 years of data in spreadsheet or graphical format

About the LevelCon Cloud Portal

LevelCon’s highly robust and extremely flexible web portal delivers all your asset data on one, easy to access, platform.

Customise the portal to your own individual style. Make it your own and make it as simple as you need.

Accessed by any network connected devices. Plus, it auto-formats to your hardware. Whether you are on PC website or using the Android/Apple app your data is always secure and available at your fingertips.

- Set Maximum and Minimum Product Levels for Bitumen Tanks

- Monitor Usage

- Monitor and report current levels.

- Customise your dashboard to information you need to know about

- Daily e-mail reports can look at trends up to the last 3 years in spreadsheet or graph styles

- Create e-mail, text, alerts for level changes.

- View all assets on a single dashboard via Google Maps

The StarPin and Radar Sensor are not just for stationary tanks. Ideal for Tanker trucks. Used for GPS tracking to monitor the location and the level of contents inside as it moved from site to site. In addition, why not try Satellite Tank Level Monitoring with the F100M.

The StarPin and Radar Sensors provide a wireless tank level monitoring solution for Bitumen Emulsion. However, they are also ideal for tank level monitoring of the following products Aggressive chemicals, fuels (Petrol, Methanol, Diesel), Acids (Sulfuric Acid, Hydrochloric Acid), Liquid Fertilizers, Fracking Fluids, Lubricants + Oils, Waste and Wastewater.

Contact us to learn more.