Medical devices rely on compact, densely populated printed circuit assemblies (PCAs) where accuracy, repeatability, and safety are critical. Technicians need a reliable way to test complex boards. This is important for repair, maintenance, and research. They want to do this efficiently without causing damage or wasting time.

Automated PCB probing systems for medical devices address this challenge. Simply by replacing slow, manual probing with highly precise, repeatable, and software-controlled testing. The Huntron Access Prober range is designed specifically for low-volume, high-mix environments. Those common in medical electronics repair, refurbishment, and R&D.

The Challenge of Testing Medical Device PCAs

Medical electronics present unique testing constraints:

- PCAs are compact and densely populated

- Probe placement must be highly accurate to avoid component damage

- Multiple board types are tested in small quantities

- Manual probing is slow, inconsistent, and operator dependent

As a result, service centres and laboratories require an automated solution that delivers precision without sacrificing flexibility.

Automated PCB Probing with Micron-Level Accuracy

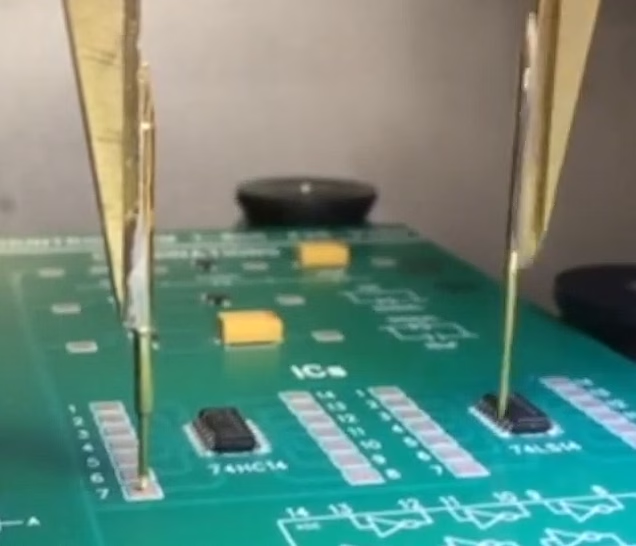

Huntron Access Probers use micro-stepping motors and linear encoders to position probes with micron-level accuracy. This precision allows repeatable access to fine-pitch components and test points. Especially those that are difficult or impractical to probe manually.

Once a test sequence is initiated, probing operations run independently. Consequently, technicians can focus on other tasks while tests are executed automatically, improving overall productivity and consistency.

Optimised for Low-Volume, High-Mix Medical Environments

Unlike high-volume production testers, Access Probers are optimised for environments where board designs frequently change. Using Huntron Workstation software, technicians can create and store repeatable test profiles. Therefore, making it easy to switch between different PCAs without lengthy reconfiguration.

When CAD data is unavailable, an integrated camera enables precise targeting of probing locations directly on the board. This capability is particularly valuable in medical repair and maintenance, where documentation is often incomplete or unavailable.

Integration with Existing Test Equipment

Access Probers integrate seamlessly into existing workflows. They can be configured to operate alongside external electronic measurement instruments, including:

- Oscilloscopes

- Digital multimeters (DMMs)

- LCR meters

This flexibility allows organisations to enhance current test processes rather than replace them, protecting existing investments while improving test automation.

Access Prober Models for Medical Electronics

Access 2 Prober

A benchtop system featuring a single flying probe head, ideal for service benches and laboratories.

Key capabilities include:

- Automated probing for manual test environments

- When paired with the Tracker 3200S, enables automated, power-off Analog Signature Analysis (ASA) testing

- Compact footprint suited to medical repair centres and R&D labs

Access DH2 Prober

A higher-capability system designed for more complex testing requirements.

Key capabilities include:

- Dual flying probe heads for increased test flexibility

- Ability to probe across components with minimum spacing of 50 mils (0.050 inches / 1.27 mm)

- Integrated ASA testing

- Optional 4-wire measurement configuration for increased accuracy

- Mobile cabinet for flexible deployment

Speed, Repeatability, and Ease of Maintenance

By automating the probing process, Access Probers achieve test speeds up to ten times faster than manual methods. More importantly, automation improves repeatability, reducing variability between operators and test runs.

System maintenance is straightforward, requiring only occasional lubrication of the axis rails. This low-maintenance design supports long-term reliability in demanding service environments.

Why Automated PCB Probing Matters for Medical Devices

Implementing automated PCB probing for medical devices delivers clear operational benefits:

- Higher probing accuracy on dense PCAs

- Faster diagnostics and reduced turnaround times

- Improved repeatability and test consistency

- Better utilisation of skilled technicians

- Seamless integration with power-off ASA testing

Conclusion

Huntron Access Probers offer a precise and flexible way to test PCBs. They are great for medical electronics repair, maintenance, and R&D teams. By using small probes, automated processes, and current measurement tools, these systems provide reliable diagnostics. They also keep up with the complexity of today’s medical devices.

Finally, Do you want to know more? Contact us.