Model DFM D is a diesel fuel flow meter. It measures diesel fuel consumption in the fuel lines of vehicles and stationary engines. As well as providing engine statistics in various modes of operation. In addition, this model works with diesel, heating oil and other liquid fuels with kinematic viscosity of 1.5-6mm²/S.

How does DFM D Diesel Flow Meter work?

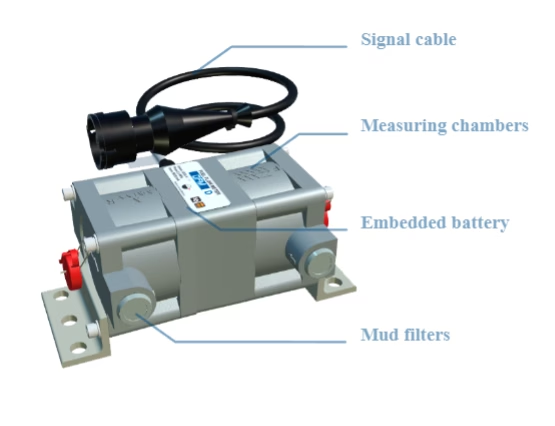

The DFM D diesel flow meter is installed into both lines of the fuel system. It has two measuring chambers. One chamber measures the supply (feed) fuel lines and the other for fuel returned. Firstly, the flow meter measures fuel consumption in each line. It then calculates the difference between supply and return. This value is then stored on an appropriate counter.

The results can be sent to Diesel Fuel Monitoring, GPS Fleet or Telematics Monitoring Systems to provide real time information for further analysis and decision making.

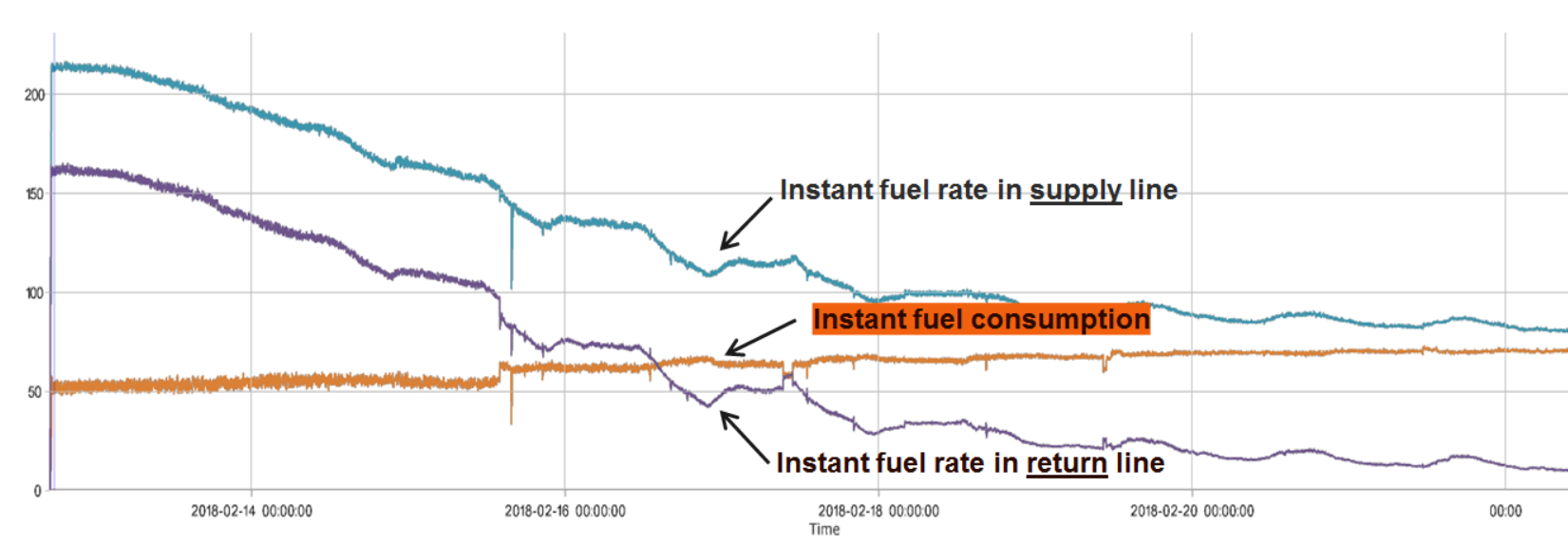

What information does it provide?

Fuel Consumption – Instant fuel consumption, Hourly fuel consumption in feed and return lines, Total fuel consumption and Total fuel consumption – “Idling”, Overload, Negative (return exceeds supply) and more.

Engine Operating Time – Total operating time in hours, operating time in “Idling”, overload, negative, Supply chamber, Return chamber and more.

Special features – Engine operating time in “Tampering” and “Interference” mode, current engine operation mode as per fuel consumption rate, fuel temperature, battery charge value,

There are two types of Flow Meters for Diesel available.

DFM CD – Two chambers equipped with a display. This provides a standalone digital flow meter for diesel fuel solution for calculating diesel consumption. Therefore, not requiring connection to the internet.

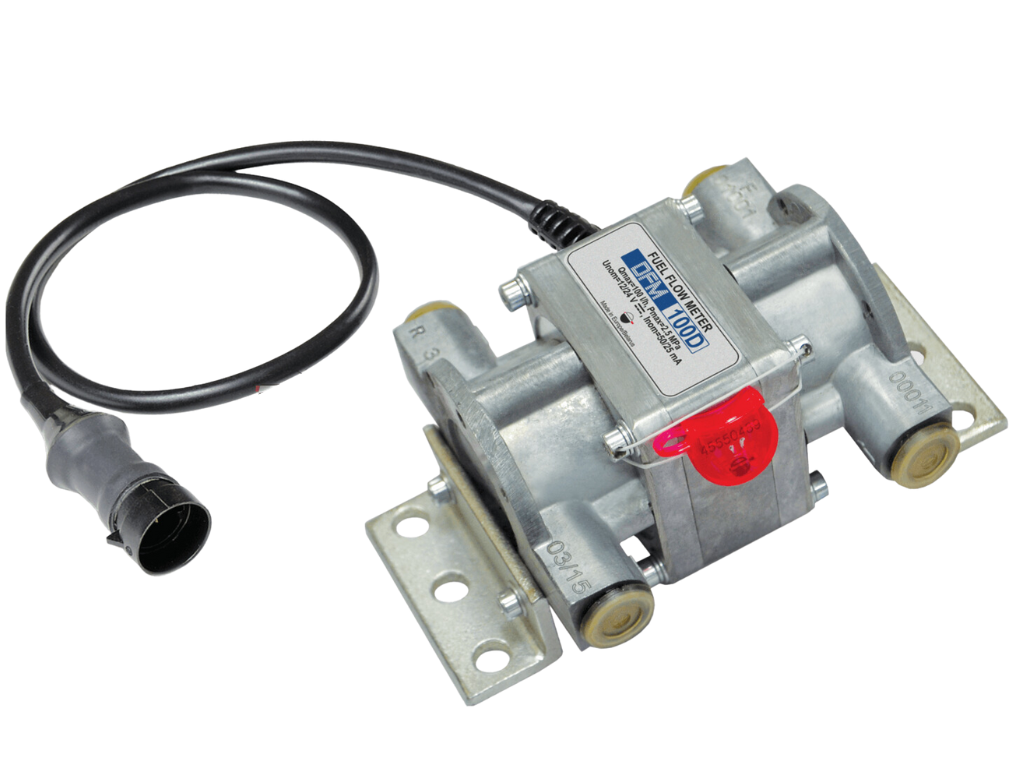

DFM D – Two chambers with output signal cable. Output can be Pulse (K), RS-232, RS-485 or CAN j1939 or S6 protocols.

Diesel Fuel Meters – Flow Rates

| Model | Chamber volume ml | Minimum flow rate in each chamber, l/h | MAX flow rate in each chamber, l/h |

| DFM 100D | 5 | 10 | 100 |

| DFM 250D | 12.5 | 50 | 250 |

| DFM 500D | 20 | 100 | 500 |

Advantages

Built in Battery – if the external power source is unavailable, the DFM registers data to the internal memory. When power is restored, accumulated data will be transferred to the on-board monitoring fleet management system.

Replaceable mud filter – Installed in the inlet of DFM D. It protects flow meter supply chamber from dirt and sand by a fine filter. This increases the durability and reliability of the flowmeter. The filter can be easily replaced on site.

Easy Installation – Exact placement of the Diesel Fuel Flow Meter depends on the fuel system specifications of the vehicle. However, the operations manual offers excellent general guidance.

Daisy Chain several Flow Meters together and to a Telematics Device – Install several DFM D and connect them to telematics unit via a single cable. Perfect for those items with more than one diesel consuming unit. Such as a Boat with two motors.

How to choose the right model for your application?

Select high pressure fuel pump type

- Common Rail Fuel System – Select DFM D Model according to fuel rate

| Max. Flow rate per hour | Model |

| Under 90 litres/hour | DFM 100D |

| 90-220 litres/hour | DFM 250D |

| 220-500 litres/hour | DFM 500D |

- Unit Injector Fuel System – Select DFM D Model according to fuel rate

| Max. Flow rate per hour | Model |

| Under 90 litres/hour | DFM 100D |

| 90-220 litres/hour | DFM 250D |

| 220-500 litres/hour | DFM 500D |

- Jerk Pump Fuel System – One chamber DFM fuel flowmeter needed

| Engine Power, Kw | Model |

| Under 80 | DFM 50 |

| 80-150 | DFM 90, DFM 100 |

| 150-300 | DFM 220, DFM 250 |

| 300-600 | DFM 500 |

- Distributor Type Pressure Pump – One chamber DFM fuel flowmeter needed

| Engine Power, Kw | Model |

| Under 80 | DFM 50 |

| 80-150 | DFM 90, DFM 100 |

| 150-300 | DFM 220, DFM 250 |

| 300-600 | DFM 500 |

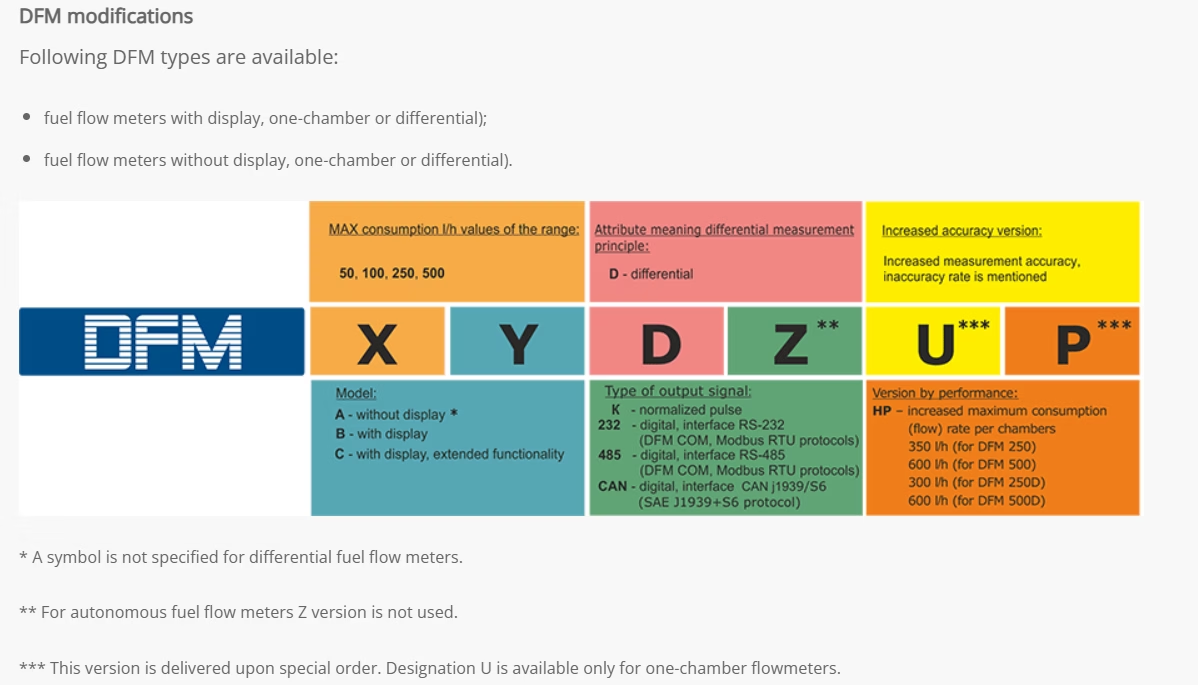

DFM Modifications

Tools for DFM D Installation

- Mounting Brackets (Order separately, not part of delivery set)

- Automotive hand tool kit – wrenches, drive sockets, screwdrivers

- Pyrometer (allows measurement of temperature remotely)

- Transparent canister 5 or 10 litres – used for checking fuel return line

- S6 SK or S6 BT service adaptor

- Service DFM software or Service S6 DFM mobile app

Installation and Connection of the DFM D

The DFM D Differential Fuel Flow Meter is installed directly into both the supply (feed) and return lines of a vehicle’s fuel system. Each chamber of the meter is clearly marked:

“F” for the feed line

“R” for the return line

The exact installation location will vary depending on the layout and specifications of the vehicle or equipment. For detailed guidance, please refer to the DFM D Operation Manual.

Multiple Units – One Telematics Cable

In systems with multiple fuel-consuming units—such as riverboats with dual engines, generators, boilers, or auxiliary systems—multiple DFM D units can be installed and connected to a single telematics device via one cable. This setup simplifies wiring and ensures centralised fuel data collection.

For instructions on configuring multiple meters via CAN or S6 interfaces, refer to our CAN/S6 Telematics Interface documentation.

For more information or pricing, contact us.

Specifications

| Connecting Thread | M14 x 1.5 |

| Nominal Pressure | 2 bar |

| MAX Pressure | 25 bar |

| Supply Voltage | 10-45 V |

| Over Voltage | <100 V |

| Current Consumption ma (12V/24V) | 25/50 mA |

| Operating Temperature (without/with display) | -40°+85° -20°+60° |

| Ingress Protection Rating | IP54 |

| Relative accuracy error per chamber | Not more than 1% |