In the world of precision engineering, every millimetre counts. In addition, accuracy is crucial and public safety is paramount. Engineers rely on a multitude of innovative tools and technologies to measure the performance of their innovations. One such instrument is the strain gauge—a device that measures the smallest of changes in mechanical strain. It has revolutionised the way we understand structural integrity.

In a recent article written by Dewesoft legend Grant Smith (linked below), delves into the fascinating world of strain gauges. Exploring their principles, applications, and the invaluable contributions they make to the field of engineering.

What is a Strain Gauge?

At its core, a strain gauge is a sensor designed to measure strain or deformation in an object subjected to external forces. These forces can be tension, compression, torsion, or a combination of them. Strain gauges are found at the heart of load, force, and pressure transducers. Such as load cells and force transducers.

Principles of Operation:

The fundamental principle behind strain gauges is the concept of the piezo resistive effect. Certain materials, such as semiconductors and metallic alloys, exhibit a change in their electrical resistance when subjected to mechanical strain.

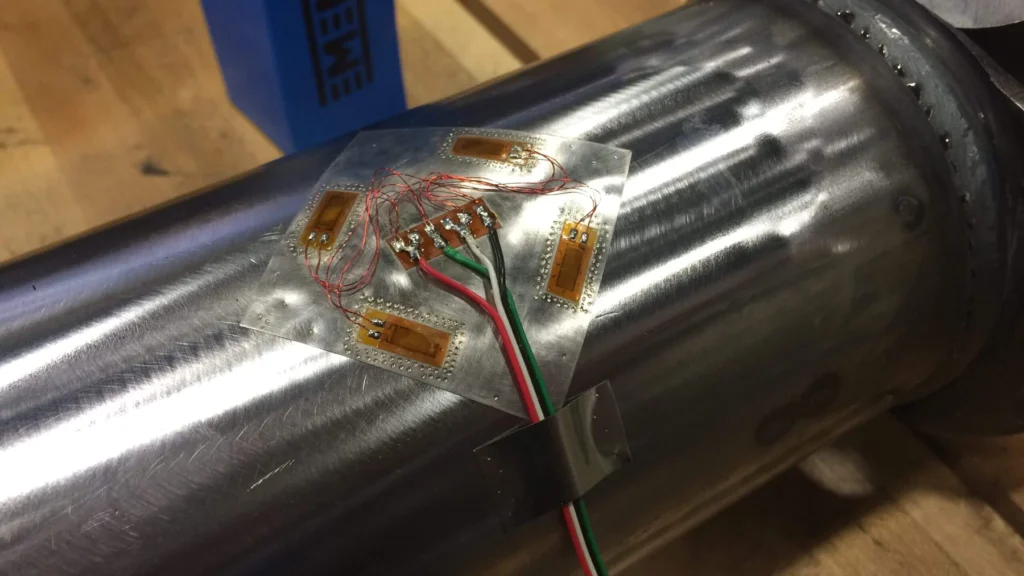

Strain gauges today typically consist of a flexible wire or foil grid patterned in a specific arrangement and attached to the surface of the object under examination. When the object deforms, the strain gauge experiences changes in its electrical resistance.

As the strain gauge only, senses change in one direction, multiple gauges are often used. Therefore, each gauge is applied in different directions to capture the full effect of movement.

So where does a Data Acquisition System come into play?

Outputs sent to a signal conditioner. This signal conditioner powers it, provides controls for “balancing” it before each test, and amplifies its small voltage output to one more suitable for digitising. The DAQ system digitises the conditioned signal, displays it on a screen, and records it to disk.

DAQ systems designed to handle strain gauges often have at least eight channels, and sometimes into the hundreds of channels in large-scale testing applications.

Applications for Strain Gauges:

Firstly, strain gauge measurement is used in all major industries. For example, aerospace, automotive, civil engineering, manufacturing, medical and more. Found in unexpected places such as our homes. In this article, you will find an extensive list of common and important strain gauge specific applications.

Finally, Metromatics proudly sell, service and support the Dewesoft product range in Australia and New Zealand.