This application note on Thermocouple Transmitters was supplied by our valued supplier Acromag

Defining the problem:

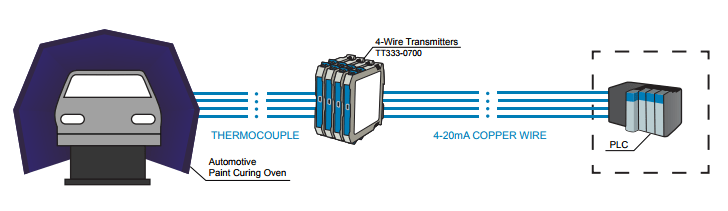

The area around an auto manufacturer’s paint curing ovens is at elevated temperatures affecting the performance of locally installed instrumentation. Placing Signal Conditioners rated for high operating temperatures near the ovens allows the PLC controlling the process to be mounted in a lower temperature area. The Signal Conditioner will convert Thermocouples to 4–20mA outputs. Running current loops over long distances instead of Thermocouples reduces costs and minimises the potential for measurement errors due to electrical noise.

System Requirements:

An Isolated Thermocouple to Current Signal Conditioner with a high operating temperature, Acromag model TT333-0700, that is rated for –40 to 80°C. The TT333-0700 output powers the loop to the PLC. Also, the plant has standardised on PLCs with less expensive current input cards over temperature input cards. This makes installations and programming throughout the plant more consistent.

Implementing the Solution:

- Program the TT333-0700 with software from either a Windows

based computer or with the Acromag Agility™ Config Tool. This

programming application for Android devices is available at no

charge from the Google Play Store. - Connect the shorter Thermocouples to the locally installed

Acromag Transmitters and run 4-20mA copper wires from the

Transmitters to the PLC panel.

Products Used:

- Loop powered Isolated Thermocouple Transmitters TT333-0700

- Programming options: TTC-SIP software kit or Android based

Acromag Agility™ Config Tool application downloaded from the

Google Play Store

Why Acromag?

The installation meets manufacturer’s process standards while delivering high performance with simple and fast set-ups.

For further information, please contact us.