Managing inventory levels can be a complex and challenging task. This is because manual methods such as dipping or gauging are often prone to human error. This leads to problems such as over and under stocking. Tank size and shape is another reason why it’s difficult to get accurate tank level measurements. Various shapes and sizes make it difficult for employees to accurately measure fluid levels.

Other issues such as, limited access and safety risks are other reasons why manually measuring inventory levels is difficult. For example, tanks located in remote locations can be difficult to access on a regular basis. This can cause delays in refilling and project progress. Finally, because traditional methods require employees to climb ladders or access confined spaces, risk of falls or exposure to harmful substances is another liability and risk that companies and employees need to consider when manually checking tank inventory levels.

Due to these reasons, businesses with large or multiple tanks can greatly benefit from wireless tank level sensors. This is because they simplify the inventory management process and reduce the risk of injury and inaccurate measurements.

Real-time data

One of the benefits of tank level sensors is that they provide real-time data on tank inventory levels. This allows business to use more accurate and regular data on tank levels. To top things off, this data data is also accessible remotely. Thus allowing business to monitor inventory levels from anywhere and at any time. This is particularly beneficial for business with remote and difficult to access tanks because it allows them to monitor tank levels more often and save money on travel time, man hours and potential safety liability costs.

Improved accuracy

Wireless tank level sensors are one of the most accurate and reliable ways to attain data on tank levels. Thanks to their accuracy and regular reporting overstocking and under-stocking risks are greatly minimised. Furthermore, thanks to more accurate data, businesses can also optimise their inventory levels. Therefore allowing them to free up valuable storage space.

Cost savings

By optimising inventory levels, businesses can also reduce waste and lower costs associated with overstocking or under-stocking. Business will also save man hours and on potential injuries often associated with manual tank measurements. Minimising these risks will lead to a significant cost savings over time.

Increased Efficiency

Wireless sensors also allow businesses to automate the inventory management process. They also increase efficiency, productivity and free up time for employees to focus on other tasks.

Customisable Alerts

These wireless sensors can also send alerts when inventory levels reach a certain point. This allows businesses to schedule deliveries or refills in advance. Thus preventing the risk of stock outs or production delays.

Greater Flexibility

Users can install wireless tank level sensors on tanks of various sizes and shapes. This provides greater flexibility for businesses with multiple tanks. Inventory management software allows users to easily access sensor data. Thus providing users with a more comprehensive view of inventory levels.

The LevelCon Wireless Tank Level Monitor F100M

One of the wireless tank level monitor solutions we carry is the The LevelCon Wireless Tank Level Monitor F100M. This is a mobile based remote telemetry monitor that provides real time data on inventory levels, temperatures, humidity, pressure levels and more. To use, simply pair this solar powered monitor with sensors based on what you want to measure. Once collected, data is viewable via the LevelCon Web Portal and app. Typical applications for this unit include:

- Product Level Monitoring of fuel, water, lubricants, chemicals, gases and solids

- LP or Propane Level Monitoring

- Frac Tanking Monitoring

- Generator Fuel Level Monitoring

This Wireless Tank Level Monitor is also M1-LTE/NB-IoT based. As a result, it uses a multi carrier mobile sim to function but also has a Global star Satellite option for when mobile sim use is unavailable. Furthermore, installation is a breeze thanks to its wireless features. It is great for single tank monitoring or can work as part of a bulk facility network or as a multi tank monitor. Also, because this unit is housed in an IP67 enclosure it is durable and can operate at temperatures -40° to 70°C.

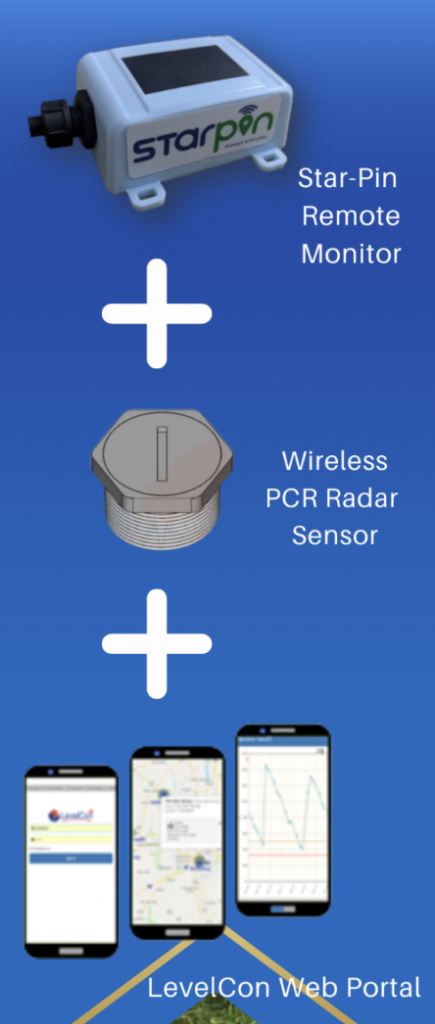

Remote Tank Level Monitoring Starpin

The Starpin is a small yet reliable remote tank level monitoring solution by LevelCon. It is also solar powered and mobile based. To use, simply pair this unit with sensors based on what you want to monitor. This includes, pressure, sonic, radar or lidar sensors. Once collected, data is displayed on the LevelCon Web Portal and App. Typical applications for this monitor incude:

- Product level monitoring of fuel, water, lubricants, Chemcials, gases and solids

- Industrial LP Gas or Propane level monitoring

- Frac Tank Monitoring

- Backup Generator Fuel Level Monitoring

Other features of the Starpin Monitor include: automatic sensor check for level change detection, optional satellite communication, free GPS positioning and Mesh Network configuration. To learn more about this product, please click here.

The Benefits of Tank Level Sensors

In summary, wireless tank level sensors can have a significant impact on inventory management. This is because they provide real-time data, improve accuracy, increase cost savings & efficiency, provide customisable alerts and offer greater flexibility. By implementing wireless sensors, businesses can streamline their inventory management process, optimise inventory, reduce costs and increase productivity.

Contact Us

If you would like more information about these products or to know which is right for your application, please contact us, here.