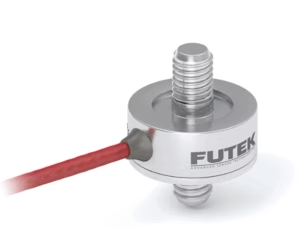

Embarking on the journey of mechanical innovation requires a foundation built on precise measurements and controlled operations. Central to this is the understanding and monitoring of torque within rotating systems. FUTEK’s strain gauge Rotary Torque Sensors emerge as a frontrunner in this domain, offering a range of model options tailored for diverse applications.

Explore The Models:

Firstly, FUTEK presents a range of these products. For example encapsulating models like Rotary Drive, Rotary Hex, and the pivotal Rotary Shaft-to-Shaft models. These variants cater to different torque measurement needs. As well as an expansive capacity range. Therefore, rendering them versatile for various operational demands.

Seamless Integration and Expanded Capacity Range:

The rotary sensors harbour a broad capacity spectrum, ranging from a modest 0.5 Nm all the way up to a robust 1000 Nm. This wide variety ensures there’s a perfect match for your specific torque measurement needs. Integrating these sensors is a breeze with compatibility extending to FUTEK’s USB Solutions, Digital Displays, Universal Amplifiers, and the intuitive SENSIT Software.

Accessorise and Calibrate:

With every sensor, FUTEK offers a complementary set of compatible accessories and instruments. This is coupled with a calibration service accredited by FUTEK’s reputable laboratory. Therefore, ensuring your torque measurement system operates with pinpoint accuracy right out of the box.

Output Signals Tailored for You:

Standard output options are provided in mV/V or VDC formats, catering to different data processing requirements. These varied output signals ensure a seamless interface with your monitoring and control systems, simplifying the integration process.

Maximised Rotation and Encoded Models:

Some models in this exquisite range boast an impressive maximum rotation of 50,000 Rotations Per Minute, accommodating high-speed applications with ease. Additionally, select models are equipped with encoders to measure Rotational/Linear displacement, Angle, or RPM, thus offering a more granular insight into your system’s operation.

Dive Deeper into Torque Measurement:

FUTEK’s Rotary Torque Sensors are more than just instruments; they are a gateway to an enhanced understanding of your mechanical systems. The precise torque measurement, coupled with the versatility of model options and accessory availability, makes this range a prized asset for engineers and technicians alike.

Applications of Rotary Torque Sensors

Used in a multitude of fields. Here are a few applications:

Industrial Automation:

From monitoring torque in rotating shafts to ensuring machinery operates within set parameters, these sensors are fundamental in modern industrial automation.

Automotive Testing:

Accurate torque measurement is crucial for testing automotive parts such as engines and transmissions. A rotary torque gauge provides the necessary data to ensure optimal performance.

Aerospace and Defence:

In sectors where precision and reliability are paramount, these products play a crucial role in testing and monitoring systems to uphold the stringent standards.

Medical Equipment:

Used in testing and monitoring medical equipment, ensuring they operate accurately and reliably.

Price and Selection

The price of a Rotary Torque Sensor can vary based on its features, capacities, and the specific model. However, investing in a high-quality torque transducer is invaluable. Therefore, ensuring accurate torque measurement. In addition, optimal performance of your systems.

In conclusion, whether it’s the robust shaft torque sensor or the sophisticated inline rotating torque sensor, selecting the right Rotary Torque Sensor is crucial for accurate measurement. Therefore, with their ability to provide precise torque data and their wide application range. They are indeed a key ingredient in modern engineering and machinery monitoring.

Metromatics proudly distribute FUTEK’s product range in Australia and New Zealand.

Contact us now for more information.