The HBK Microstrain 3DM-CV5-AR is an Industrial Tilt OEM AR Sensor that provides precise Attitude Reference (AR) Information.

Firstly, this unit is a combination of a Triaxial Accelerometer, Gyroscope, Magnetometer and Temperature Sensors. Therefore, it ensures comprehensive and precise measurement of motion, orientation, and environmental conditions. Resulting in accurate and reliable data.

In addition, this unit has Dual on board processors with an auto adaptive extended Kalman Filter making it highly responsive in real time applications. This set up enhances the accuracy of dynamic attitude estimates.

The Inertial Measurement Unit (IMU) includes direct measurement of acceleration, angular rate, Delta-theta, and Delta-velocity.

In addition, it has compensation options. These include automatic compensation for magnetic anomalies, gyro and accelerometer noise, and noise effects. The computed outputs vary between models and can include roll, pitch, and yaw. All sensors are fully temperature-compensated and calibrated over the operating temperature. Micro-Electro-Mechanical Systems (MEMS) technology allows for highly accurate, small, light-weight devices.

FEATURES AND BENEFITS Industrial Tilt OEM AR Sensor 3DM-CV5-AR

The Sensor: High Performance Accelerometer (8g standard options of 2g, 4g, 20g, 40g) Super stable Gyro (8 dph in-run bias, offset temperature hysteresis 0.05°/s, ARW 0.3°/hr;

- IMU Sampling rate up to 1000 Hz

- Auto adaptive EKF output rate up to 500 Hz

- IMU and EKF are independently configurable outputs

- Forward compatible MIP Protocol optimises bandwidth

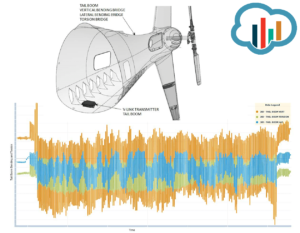

- SensorConnect Software for configuration, control, display and logging

- CNC Anodised Aluminium enclosure

- Precision Alignment features

- Compact and Low Profile

- Weights 11 grams

- TTL UART (up to 921600 BAUD) interfaces

- -40° to +85° Operating Temperature

SOFTWARE

SensorConnect software is a user-friendly program for device configuration. MIP Monitor (MicroStrain Internet Protocol) can also be used. Both packages provide for device configuration, live data monitoring, and recording. Alternatively, the MIP Data Communications Protocol is available for development of custom interfaces and easy OEM integration. The sensor operates independent of computer platform, operating system, or coding language.

Contact us to explore how this solution can revolutionise your navigation needs