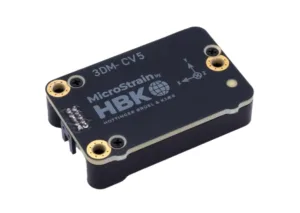

The HBK Microstrain 3DM-CX5-AHRS is an OEM AHRS (Attitude and Heading Reference System) Sensor.

Firstly, this high-performance unit features an IMU. This allows a direct measurement of acceleration and angular rate. In addition, it is fully temperature compensated and calibrated over the operating temperature and uses MEMS Technology.

Optimal combination of measurement qualities is achieved in the 3DM-CX5-AHRS unit with use of a triaxial accelerometer, gyroscope, magnetometer, and temperature sensors. Packaged in one unit.

Secondly, designed for demanding OEM applications. Featuring an onboard Extended Kalman Filter for attitude estimation. The IMU and EKF provide independently configurable outputs. Housed in a compact and low-profile CNC Anodised Aluminium package. The operating temperature range is from -40 to +85°C.

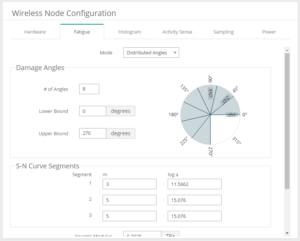

SensorConnect Software is ideal for configuration, control, display, and logging. Whilst the MIP Protocol optimises bandwidth.

FEATURES AND BENEFITS OEM AHRS Sensor

- Dual on-board processors run a new Auto-Adaptive Extended Kalman Filter (EKF) for outstanding dynamic attitude estimates

- Bias tracking, error estimation, threshold flags, and adaptive noise modelling allow for fine tuning to conditions in each application

- Accelerometer noise as low as 20 ug/√Hz

- Smallest and lightest industrial AHRS with Adaptive Kalman Filter available

- SensorConnect enables simple device configuration, live data monitoring, and recording

- Development Kit available

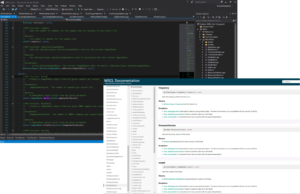

- The MSCL API allows easy integration with C++, Python, .NET, C#, Visual Basic, LabVIEW and MATLAB environments. Robust, forward compatible MIP packet protocol

- MIP open byte level communication protocol

- Automatic magnetometer calibration and anomaly rejection eliminates the need for field calibration

- Automatically compensates for vehicle noise and vibration

SOFTWARE

SensorConnect software is a user-friendly program for device configuration. MIP Monitor (MicroStrain Internet Protocol) can also be used. Both packages provide for device configuration, live data monitoring, and recording. Alternatively, the MIP Data Communications Protocol is available for development of custom interfaces and easy OEM integration. The sensor operates independent of computer platform, operating system, or coding language.

Contact us to explore how this solution can change your navigation needs in OEM applications.