Dewesoft offer Machine Condition Monitoring Solutions that identify significant changes in machinery whilst in operation. Generally, changes in the operation of machinery such as vibration, temperature and noise indicate a developing fault or malfunction. It enables preventative maintenance to be conducted rather than completely breaking down and the machine being off line for hours or days.

Main Features of the Machine Condition Monitoring Solution

POWERFUL WEB BASED SOFTWARE – In addition, the Software provides an overview of the machinery state.

INDEPTH MACHINE CONDITION ANALYSIS – Firstly, FFT-Analysis, time domain analysis, orbit plot, order tracking, waterfall diagram, trend statistics, bearing fault detection and also many more software features.

HISTORICAL DATA STORED IN DATABASE – Secondly, data is stored. Used to monitor trends or for comparison.

THIRD PARTY CONNECTIVITY WITH OPC UA PROTOCOL – In addition, data can be integrated into any 3rd party control system.

DATA ACCESS FROM ANYWHERE – Because data can be access from local computer, mobile phones, control systems or remotely via pre configured web browser application.

UNLIMITED INPUT CHANNELS – Dewesoft’s Data Acquisition Systems offer unlimited input channel configurations. To allow monitoring all at the same time.

DISTRIBUTED SYSTEM – Designed to be distributed under any condition. Also EtherCAT technology allows devices to be placed near the sensors and connected with a single cable for power, data and synchronisation.

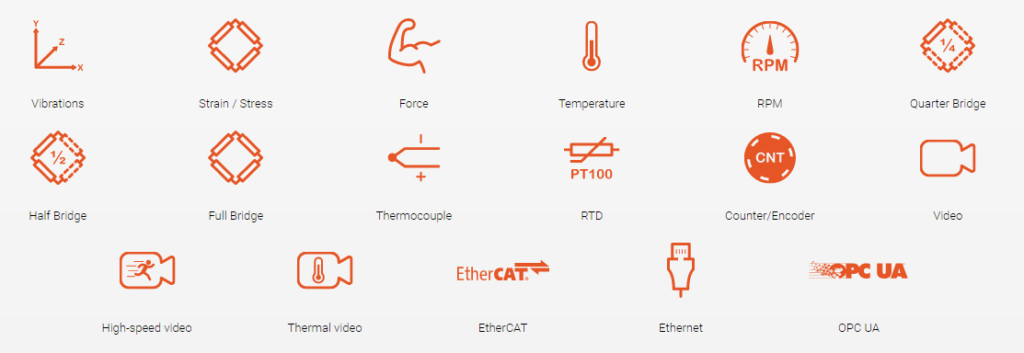

ANY SENSOR – In addition, the input amplifiers offer support for any accelerometer, temperature, pressure and rotatory torque sensors that need to detect rotating machinery issues.

LIFETIME FREE SOFTWARE UPGRADES AND SUPPORT – Dewesoft offer lifetime FREE software upgrades and technical support to all their users.

Frequently asked Questions:

Why use permanent conditioning monitoring techniques?

Firstly, machine health monitoring allows users to understand the condition of your machines in detail. Secondly, it enables you to perform the right maintenance at the right time.

Machine Health Monitoring System can measure the following:

- Temperature

- Vibration

- Strain Monitoring

- Pressure Monitoring

- Rotational Speed Monitoring

- Force Monitoring

Faults that maybe detected?

- Bearing faults

- Overheating

- Shaft un-balance

- Detached Mounting

- Gear Tooth Failure

- Load Misalignment

- Stator Eccentricity

- Other Machine Catastrophic failures

Which applications is Condition Monitoring used?

PULP & PAPER – blowers, conveyor belts, chippers, chip classifiers, refiners, pressure screens, screw conveyors, agitators, nip monitoring, felt rollers etc.

IRON & STEEL – raw material handling machines, conveyor belts, ship unloaders, glavanisation plants, stack reclaimers, continuous casters, cranes, rolling mills, annealing machinery, pumps, fans and gear boxes etc.

AUTOMOTIVE – wind tunnels, air handling units, pumps in paint shops, presses and transfer presses etc.

CEMENT – Crushers, gearboxes, conveyor belts, separators, fans, raw mills, ball mills, elevators and blowers

INDUSTRIAL PLANT & FACILITIES – gearboxes, UPS, AC, electric motors, fans, pumps,

Why a Dewesoft Machine Condition Monitoring System?

Dewesoft has assisted many companies and their equipment has

- Dropped repair costs by 32% on average

- Costs in maintenance are reduced by 52% on average

- Increase Plant Life

- Plus increase revenue by 17% on average

- Reduce spares inventories by 26% on average

- Increase Personnel Safety

- Cost Savings in General

Metromatics with the assistance of Dewesoft will help you to:

- Assess what phase in the project your machinery is at.

- Determine and highlight your concerns with the machinery

- Guide you through several critical stages

- Deliver you a fully customised turn key condition based monitoring solution that will deliver improved safety, visibility and efficiency of your production plant.

- Provide you technical and software support for your product

HARDWARE SOLUTIONS

There are three different machine condition monitoring solutions available.

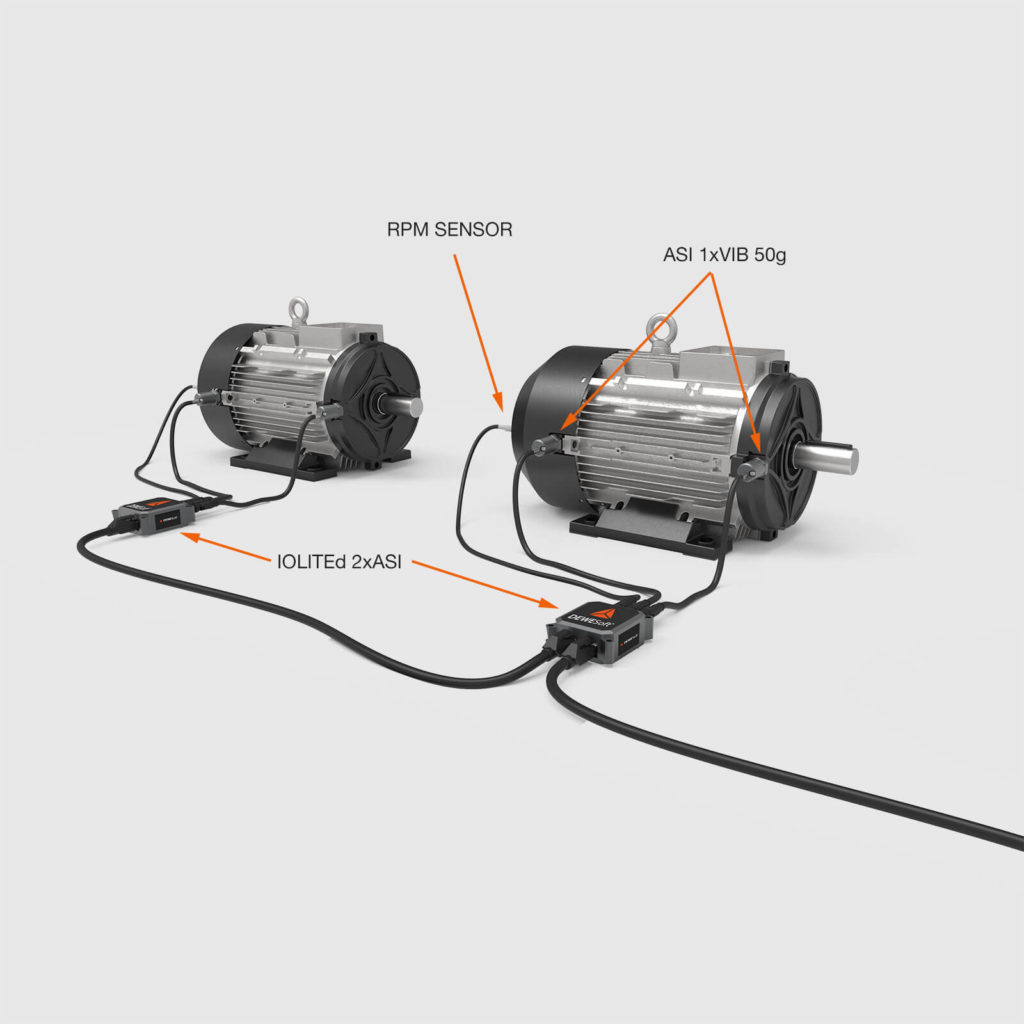

Dewesoft IOLITEd-2xASI

This device contains two analogue sensor interface channels with 40kS/s sampling speed per channel. In addition, one tacho which operates with the Dewesoft ASI-1xVIB-50g. This is a 10 kHz vibration and temperature sensor. More details below.

- IOLITEd-2xASI:data acquisition device with 2 analog input channels (with 40 kS/s sampling speed per channel) for interfacing 2 Dewesoft ASI-1xVIB-50g vibration probes and 1 digital input channel for connecting an RPM sensor (tacho).

- ASI-1xVIB-50g:a 1-axis high bandwidth (10 kHz) and low noise vibration sensor probe which also includes a temperature sensor and 3-axial low-speed accelerometer for orientation identification.

Benefits: The solution is designed for applications where distributed measurements of limitless numbers of perfectly synchronized vibration and temperature measurements are of the essence and where cost plays a significant role. Device operation is facilitated by using RJ45 connectors. The solution is bringing the DAQ device very close to the sensor eliminating long analog cables and thus reducing noise pick-up and cost.

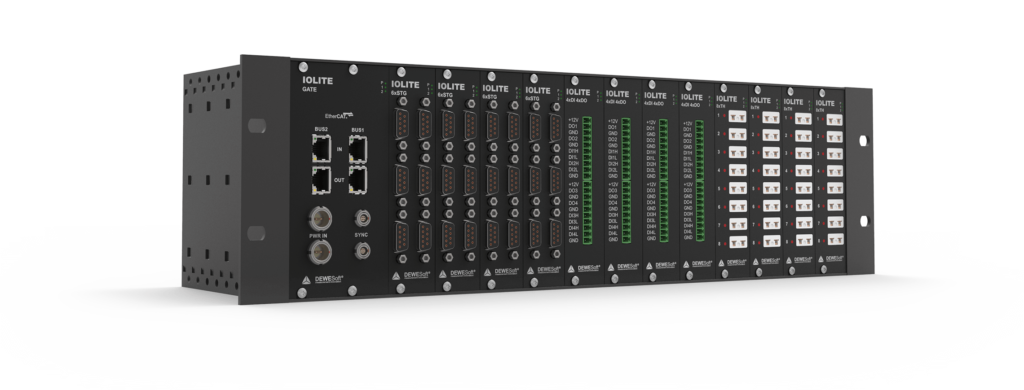

2. IOLITE Data Acquisition Systems

IOLITEr and IOLITEs are multi-channel general data acquisition devices with a wide range of input types with 24-bit resolution and 20 kS/s sampling speed. Available modules for measurement are:

- Voltage

- Current

- Strain Gauge

- Vibration (IEPE)

- Temperature – Universal Thermocouple and RTD

- Digital I/O and more

The EtherCAT Communication ensures perfect synchronisation between the devices.

Benefits: The IOLITEr and IOLITEs are ideal for those requirements with a large amount of channels. Plus, they are part of a wider EtherCAT measurement network. IOLITEr and IOLITEs also feature a secondary EtherCAT bus that can be used for parallel real-time data output to a 3rd party control & protection system.

Krypton Rugged Data Acquisition System

The KRYPTON EtherCAT DAQ Devices feature 3-8 measurement inputs in a rugged, waterproof and high temperature package for harsh environments. Linked together using a single rugged cable with Lemo connectors for power, data and synchronization.

Benefits: In harsh environments, the most suitable product is the KRYPTON Devices. While fitting into the same EtherCAT chain with IOLITE devices.

See the KRYPTON rugged DAQ video.

Condition Monitoring Software

The Dewesoft machine condition monitoring software is unique on the market. It combines PC Client software with in-depth machine condition analysis features, relevant for PdM expert engineers, a high-level Web-based software layer with an overview of the machinery state, appropriate for quick decision making and Historian time-series database for permanent storage of the data.

Learn more about Dewesoft machine condition monitoring software.

System Architecture

Dewesoft Data Acquisition systems, with its wide range of analog and digital inputs, offer support for almost any kind of 3rd party sensor. Digital and analog output devices provide the ability to drive actuators or switches.

All EtherCAT compatible devices (IOLITE, KRYPTON) can be connected into the same network giving the possibility to build a virtually unlimited channel chain by using a single cable delivering power, synchronization, and data. Node-node distances can be up to 100m.

All the raw data from data acquisition devices are collected and processed by measurement units running the Dewesoft X3 Machine Condition Monitoring software. The client PC allows you to access and view data. The times series database allows you to call up recorded information. Finally, Standard Interfaces send the data to SCADA systems or Cloud Software. Such as OPC/UA or XCP to truly support Industry 4.0 applications.

Reviews

There are no reviews yet.