Accelerometers measure acceleration, vibration, and shock. They are great for a wide range of applications. In this article, we discuss how accelerometers are used in various applications including Aerospace, the automotive industry, defence and in industrial settings.

What Do Accelerometers Do?

An accelerometer is a device that measures how quickly something is moving, and in which direction. A great example is the accelerometer inside your phone. It detects when you move your phone up, down, or side-to-side.

When you move your phone, the accelerometer inside it detects the movement and sends a signal to the phone’s processor. The processor then uses this information to change the orientation of the screen and other actions. Likewise, in other applications accelerometers detect, measure and monitor movement in things such as car speed or even earthquakes.

Accelerometers in Space

In aerospace, accelerometers measure vibration and shock on aircrafts, spacecrafts and satellites. This is particularly useful because vibration and shock cause damage to equipment. It can also affect the performance of the vehicle. Accelerometers measure the vibration and shock levels during launch, flight and landing. They also monitor the health of the vehicles during operation. As a result, users are able to monitor and detect issues before they become serious issues for passengers and flight-crew aboard an aircraft.

Accelerometers in the Automotive Industry

Another application an accelerometer is within the automotive industry. In this field accelerometers measure vibration and shock levels on vehicles such as cars, trucks and trains. Vibration and shock are important markers to measure because they affect the ride comfort and safety of a vehicle. They also causes damage to components such as engines, transmissions and suspensions. An accelerometer also measures vibration and shock levels during normal operation and in different driving conditions. Doing so helps identify and diagnose problems with a vehicle.

Defence

In defence, accelerometers measure vibration and shock on military vehicles, weapons systems and structures such as buildings and bridges. Doing this is important because vibration and shock can affect the performance and reliability of equipment and structures. It also cause damage and failure. Furthermore, accelerometers also measure vibration and shock levels during testing, training and operation. This process ensures the safety and effectiveness of equipment and structures before putting them to use in high stake scenarios.

Industrial Monitoring

In industrial monitoring, accelerometers measure the vibration and shock on machinery such as pumps, motors and turbines. Vibration and shock affects the performance and lifespan of the machinery. It also causes breakdowns and downtime. To help avoid this, accelerometers are used to measure vibration and shock levels during operation. This process helps manufactures identify and diagnose problems in the machinery before a breakdown occurs.

Versatile and Reliable

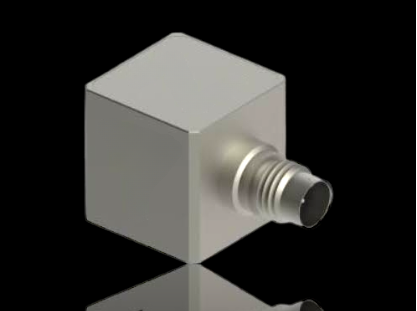

Accelerometer are versatile and reliable sensors that help a variety of industries measure vibration and shock. Their small size and lightweight design also make them easy to install in tight spaces and on moving objects. Furthermore, their wide frequency and sensitivity ranges make them suitable for measuring a wide range of vibration and shock levels. Whether in aerospace, automotive, defence or industrial monitoring accelerometers help improve performance, safety and reliability of equipment and structures.

Contact Us

To learn more, please contact us.