This differential pressure sensor measurement application came from our friends, FUTEK. To read the original article, click here.

Generally, one single pressure transducer receives pressure measurement from two different ports for comparison.

However, sometimes two different types of sensors are required for medium constraints. For example, different liquid corrosion indexes which requires different sensor bodies or medium differences such as gas vs. liquid.

Signal subtraction is achieved. This is by two differential independent pressure sensors and a control system. However, it also allows process engineers to measure the differential pressure. As well as level, flow, interface, and density (but we aren’t concentrating on these measurements today).

Firstly, the pressure measurement at the bottom of the silo or tank measures the total pressure exerted by the fluid and gas above it. But the pressure sensor at the top only measures the static pressure provided by the gases alone. So this allows the gas pressure to be subtracted from the total measurement at the bottom. Finally, leaving the pressure generate by the liquid. Therefore, allowing process engineers to determine the level of the tank, the flow level rate of change or the density of the liquid.

It is calculated using the following formula

h=(P2-P1)/(p x g)

h= height of the liquid column in metres

P2 = hydrostatic pressure at depth h

P1=pressure of the enclosed gas in the vessel

p=density of the liquid [kg/m³]

g=gravitational force [m/s²]

How the Differential Pressure Sensor Measurement Application Works

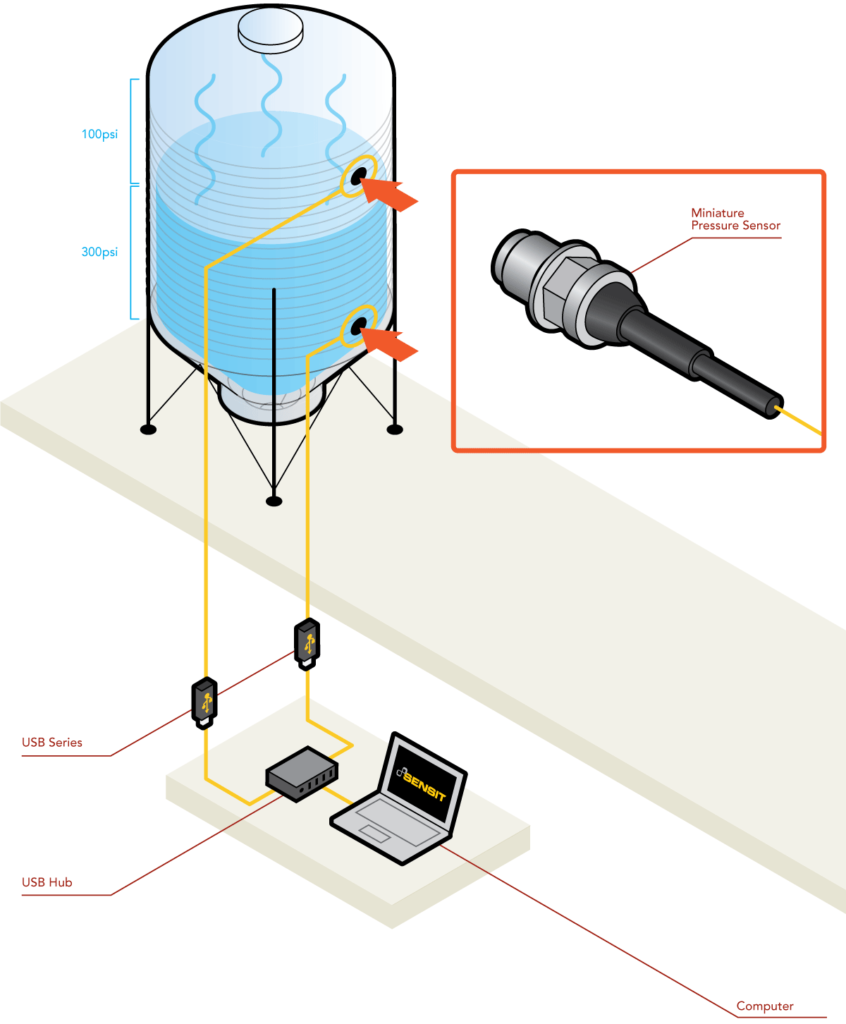

- Engineers and/or operators have installed two miniature differential pressure measurement sensors to monitor the ratio of liquid to gas within the tank

- As shown, the pressure of the fluid within the tank measures at 300 PSI. Whilst, the emitted gases measures at 100 PSI.

- These measurements are fed to FUTEK’s USB solutions to a PC using FUTEK’s SENSIT™ Test and Measurement Software. Finally, the software calculates the differential pressure within the tank.

- In this specific case, SENSIT™ calculates the differential pressure as 200 PSI.

Products Used

Two miniature pressure sensors with USB Solutions and SENSIT™ Test and Measurement Software.

- PFT510 -Flush mount diaphragm miniature pressure sensor

- USB Series – Internal PCB with internal USB Output

Please note that illustrations are conceptional. Contact us to learn more.

However, to learn more about what is a differential pressure sensor and how they work with differential pressure measurement. Be sure to check out this article from FUTEK.