This blog on Freight Train Brake Performance Testing in Winter Conditions was kindly provided by our friends at Dewesoft. It was written by Dewesoft team member Carsten Frederiksen and Magnus Skarhem, the business unit manager and head of the AFRY Test Centre. For the original article, click here.

Summary of Freight Train Brake Performance Testing

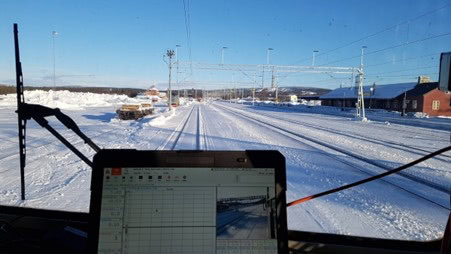

Firstly, the AFRY Test Centre in Northern Sweden carried out train set brake performance testing on behalf of their Swedish train transportation customer.

The train set with freight wagons were fitted out with different types of brake blocks also known as brake components. The purpose was to compare their brake performance in winter conditions. In addition, reference tests with disc brakes on freight wagons were also performed.

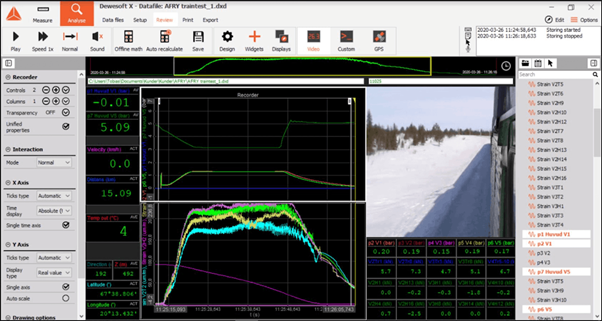

These tests measuring strain and temperature used the Dewesoft KRYPTON Data Acquisition Units in conjunction with the DewesoftX Software to deliver the results required.

About AFRY Test Centre

AFRY Test Centre is a large independent test lab in Sweden established over 30 years ago. It has a well-equipped test lab located in Borlange, Sweden. With over 17,000 employees and operating in more than 40 countries across the world, the test centre is part of AFRY an international engineering, design, and advisory company with five divisions.

The Test Centre is a business unit belonging to the Industrial and Digital Solutions division. Operations are focused on measurement, testing, analysis, and verification. AFRY’s customers are in all types of industries. Projects include verification of implants to ships, process plants and vehicles of all kinds. With projects having different requirements, AFRY believe it is important that the equipment at the Test Centre is easy to use, flexible and durable. That’s why they have used Dewesoft Hardware and Software for many years.

In 2019, the AFRY Test Centre was hired by a Swedish Train Transportation Customer as the measurement technology experts. The aim of this connection was to map the braking effect on freight trains when driving in different winter conditions.

EU regulations on rail noise

Firstly, background on this brake test project. Noise is a public health issue. It can have negative impacts on human health and wellbeing. Noise from freight wagons. Wagons with cast iron brake blocks contributes significantly to railway noise.

To address rail noise levels in Europe, the European Union has recommended changes to the European Commission Regulation (EU) No 1304/20142 (TSI Noise). This mean that the current maximum noise levels for new freight wagons applicable to existing freight wagons. Therefore, the proposed amendments would mean retrofitting cast iron brake blocks with “silent brakes”. Silent breaks are composite brake blocks or disc brakes. Composite brake blocks being the cheaper alternative.

The customer looked at the impact of the proposed changes to the Swedish Rail Network.

- Changes would reduce noise.

- However, financial impact to wagon keepers and railway operators running the wagons.

- Tests show composite brake blocks lose braking performance in severe winter conditions.

However, one way to overcome this loss is when trains arrive in Sweden from Europe, railway companies add wagons with cast iron brake blocks to trains containing wagons with composite brake blocks. Therefore, this will ensure a good level of braking performance. The only problem is the speed will have to be reduced to 80 km/h. Which leads to a reduction in capacity on an already saturated network.

The Challenges for this assignment

- Environmental Challenges: Severe cold with ice and snow but also moisture in zero degree weather

- Length of the train configuration required signal transmission over long distances and the possibility of distributing different parts of the measuring system in different carriages.

- Requirement of train’s position, speed and weather conditions to be documented each test case.

To meet the challenges, the measurement system must have.

- Good environmental resistance

- Have distributed DAQ’s in different locations in the train set

- Due to the harsh environmental conditions that test staff were to be exposed to it was crucial that system was easy to use and install.

Firstly, the AFRY Test Centre team were experienced with Dewesoft. Therefore, it was natural for AFRY to approach Dewesoft in Sweden to see if there was a suitable system for this requirement.

Measurement Setup for Freight Train Brake Testing

Another challenge of the measurement set up that the train would go in both directions. From north to south and vice versa. Therefore, the test engineer should only be required to grab the measurement lap top and move the front of the locomotive at the changeover. So, the measurement chain needed to work from both direction without adjustments to the setup.

The final solution

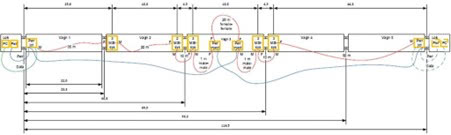

- A number of KRYPTON DAQ units daisy chained together to measure strain and temperature.

- 2 x KRYPTON-8xTH DAQ Modules

- 12 x KRYPTON-6xSTG DAQ Modules

- Power Injectors

- Power Junctions

- GPS Receiver to provide the position of the train

The train set test layout consisted of 5 wagons with a locomotive at both ends.

The KRYPTON units were distributed in wagons 3-5. Power junction and power injectors used to make sure the complete set up would be powered and measured from both directions.

Also, the complete set up was tested and simulated by the Dewesoft R&D Team at the head office in Slovenia to ensure it would work as required by AFRY.

The Dewesoft KRYPTON Modules are the perfect measurement solution. Firstly, they are flexible and could withstand the harsh environment of the Scandinavian winter. In addition, KRYPTON are rugged and distributed EtherCAT data acquisition system for field measurement in harsh environments. With IP67 protection, high shock protection and operation in extreme temperatures from -40 to +85°C. KRYPTON DAQ units connect by single cable. It provides data, power, and synchronisation. The other advantage is that the units can distributed over a large area with up distances of 100 Metres between DAQ nodes.

In addition, all KRYPTON units come with DewesoftX DAQ Software included with free lifetime upgrades. Software is easy to use and robust in functionality.

Screenshot of the measurement at the time when brakes are applied from all the train sets. The lower window shows the raw data from the strain gauge sensors and the upper window the pressure applied on the brakes and speed on the train.

Conclusion

Delivery time of this project was crucial. AFRY had a tight deadline. Therefore, a close collaboration between AFRY and Dewesoft was of high importance. Dewesoft support AFRY through the process and specified what they needed and how the measurement set up should be configured.

Dewesoft provided a reliable DAQ solution that could:

- Withstand the harsh climate

- Could work well from both ends of the train with no reconfiguration of the set up

Therefore, there was no delay in train departure to technical issues or adjustments each time the train switched direction. Less stress for the test engineer. The KRYPTON DAQ modules purchased for this specific test assignment will be repurposed for other applications. They are compatible with other Dewesoft DAQ products.

In conclusion, this was not an everyday measurement. Therefore, it was crucial to understand the set up and the challenges the customer was facing. AFRY and their customer were happy with stability of the system, the support provided to their engineers and of course the result.