Portable Crane Weighing: Ensuring Stability with Load Cell Technology

When a portable crane swings into action to lift weighty payloads, it’s not just about brute strength. Equally vital is the crane’s precision in handling weight. Ensuring not only the successful transfer of the load but also the safety of the operation. This is where load cell technology, specifically FUTEK’s LCF Load Cells, plays an indispensable role.

The Crucial Balance: Weight and Stability

Think of a crane as a giant arm that lifts and shifts. For a crane perched on a truck, stability is paramount. Every lift, especially of heavy or varied loads, has the potential to destabilise the truck. The key to preventing this is to know the exact weight being lifted. Enter the world of sensor solutions.

The Role of Tension Load Cells

In the realm of construction and industrial applications, especially those requiring low to medium duty capacities, tension load cells take the centre stage. These devices are specifically tailored to gauge tensile or “pulling” loads. Whether you’re looking at crane weight monitoring, hoisting, or rigging applications, these load cells – also known as Load Monitoring Indication (LMI), tension links, or load shackles – are your go-to tools.

These cells are usually integrated into a load block and hoist hook. This setup ensures the crane doesn’t bite off more than it can chew. As the load gets hitched and rises, the operator can track it real-time. And if the weight proves too much at any point? The operation can be halted and reversed, thanks to the load indicator in the cabin, which is equipped to halt operations, flash warnings, or sound alarms if necessary.

FUTEK LCF Load Cell Series: Built for The Heavy-Duty World

Designed for capacities of up to 100,000 and boasting a 150% safe overload threshold, the FUTEK LCF Load Cell Series is robust. Its IP protection goes up to IP65, making it a fit contender for demanding industrial scenarios.

Considering that portable cranes are tasked with handling a gamut of payloads, having a sturdy, high-capacity load cell becomes essential. It ensures that operators are always in the know about the weight variations between lifts.

The Mechanism: How Does it Work?

Given the variability and the sheer weight that portable cranes deal with, operators rely on high-capacity, sturdy load cells to provide essential measurements.

Here’s the drill:

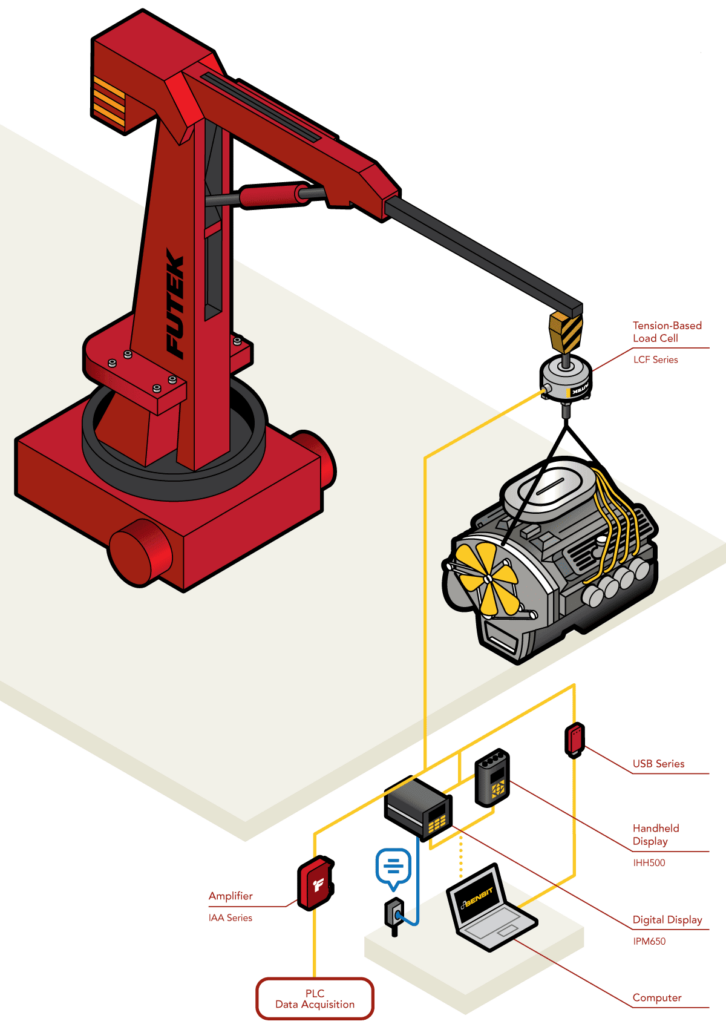

- FUTEK’s Pancake Load Cell (LCF Series) is attached to the crane’s cable.

- As the crane operates, the Load Cell gauges both the weight of the load and the cable’s endurance.

- These measurements can be amplified using an IAA Series Analog Amplifier and then displayed on a digital screen (like IPM650 or IHH500). Alternatively, they can be sent directly to a PC using FUTEK’s USB Solutions.

- If synced with FUTEK’s SENSIT™ Test and Measurement Software, operators can keep tabs, log, and even graph the data on a PC.

Key Products:

- Pancake Load Cell (LCF Series): Your primary weight measurement tool.

- Instrumentation Tools (IAA Series, IPM650, IHH500, USB Solutions): For amplifying, displaying, and transferring data.

In conclusion, when it comes to portable crane operations, knowing the weight isn’t just a good-to-have. It’s essential for safety, efficiency, and ensuring a successful lift. FUTEK’s LCF Load Cells serve as the bridge between heavy-duty operations and the precision required to carry them out safely. To learn more, contact us.