How to Use Acromag Thermocouple Transmitters in Paint Systems

Introduction

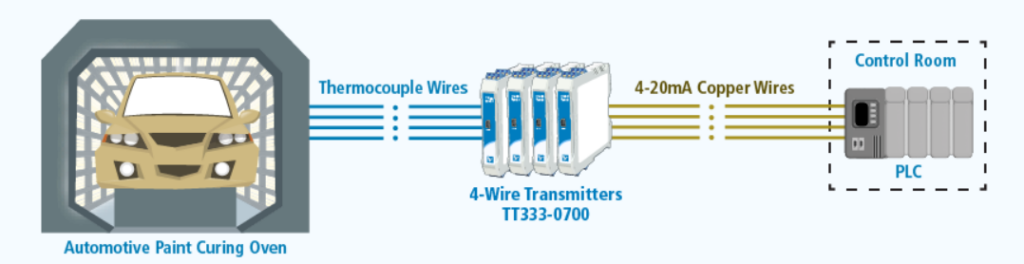

In automotive manufacturing, precision is key. Especially when it comes to the intricate process of paint curing. Ensuring the right temperature in paint curing ovens is crucial for quality control. Acromag’s TT330 Series thermocouple transmitters offer an efficient solution to monitor these high temperatures and integrate seamlessly with existing PLC systems. This blog originally from our friends at Acromag, explores how to use these transmitters to enhance temperature monitoring in automotive paint systems.

Defining the Problem

In the vicinity of paint curing ovens in auto manufacturing, elevated temperatures can adversely affect the performance of instrumentation installed nearby. The solution lies in using signal conditioners capable of operating at high temperatures. These conditioners, placed near the ovens. Therefore, allowing the process-controlling PLC to be situated in a cooler area. The key function of these conditioners is to convert thermocouple readings into 4–20mA outputs. Which are then transmitted over long distances to the PLC. This setup not only reduces costs but also minimises potential measurement errors caused by electrical noise.

System Requirements

A standout product for this application is the Acromag model TT333-0700. This isolated thermocouple to current signal conditioner boasts a high operating temperature range (-40 to 80°C). Its noteworthy feature is that it powers the loop to the PLC. Therefore, allowing for seamless integration. Additionally, standardising PLCs with current input cards, as opposed to temperature input cards, streamlines installations and programming throughout the plant, making it a cost-effective and efficient solution.

Implementation Steps for Optimising Paint Curing with Thermocouple Transmitters

- Selection of Thermocouple Transmitters: Begin with Acromag’s TT333-0700 thermocouple transmitters, chosen for their high-temperature tolerance and reliability.

- Installation Near the Ovens: Install the transmitters near the paint curing ovens. Their high operating temperature rating ensures they function optimally even in the heat-intensive environment.

- Conversion of Thermocouple Readings: The TT333-0700 units will convert the thermocouple readings into 4–20mA signals. This conversion is crucial for long-distance transmission and reduces the likelihood of errors.

- Transmitting to the PLC: The 4–20mA signals are then transmitted to the PLC. The TT333-0700’s ability to power the loop simplifies this process.

- Programming and Integration: Use either the TTC-SIP software kit or the Acromag Agility™ Config App for programming. These tools aid in integrating the transmitters with the existing PLC setup.

- Monitoring and Control: With the transmitters in place, the PLC can now accurately monitor and control the temperatures within the paint curing ovens, ensuring optimal curing conditions.

Advantages

- Cost-Effective: Running current loops instead of thermocouples over long distances is more economical.

- Accuracy: Minimises potential errors due to electrical noise.

- Consistency: Standardising on current input cards for PLCs enhances consistency in installations and programming.

- Reliability: High operating temperature range of the TT333-0700 ensures reliable performance in harsh environments.

Conclusion

Acromag’s TT330 Series, particularly the TT333-0700, provides an effective and efficient solution for monitoring temperatures in automotive paint systems. Their ability to withstand high temperatures, coupled with their conversion and transmission capabilities, makes them an ideal choice for this critical application. By implementing these transmitters, manufacturers can achieve greater accuracy, reliability, and consistency in their paint curing processes.

This blog provides a comprehensive guide on using Acromag thermocouple transmitters in automotive paint systems. It addresses the challenges, system requirements, implementation steps, and the advantages of using these advanced instruments for temperature monitoring and control.

For more information or pricing on the Acromag Thermocouples or about Optimising Paint Curing with Thermocouple Transmitters, contact us. Watch the video below for illustrative outlook.