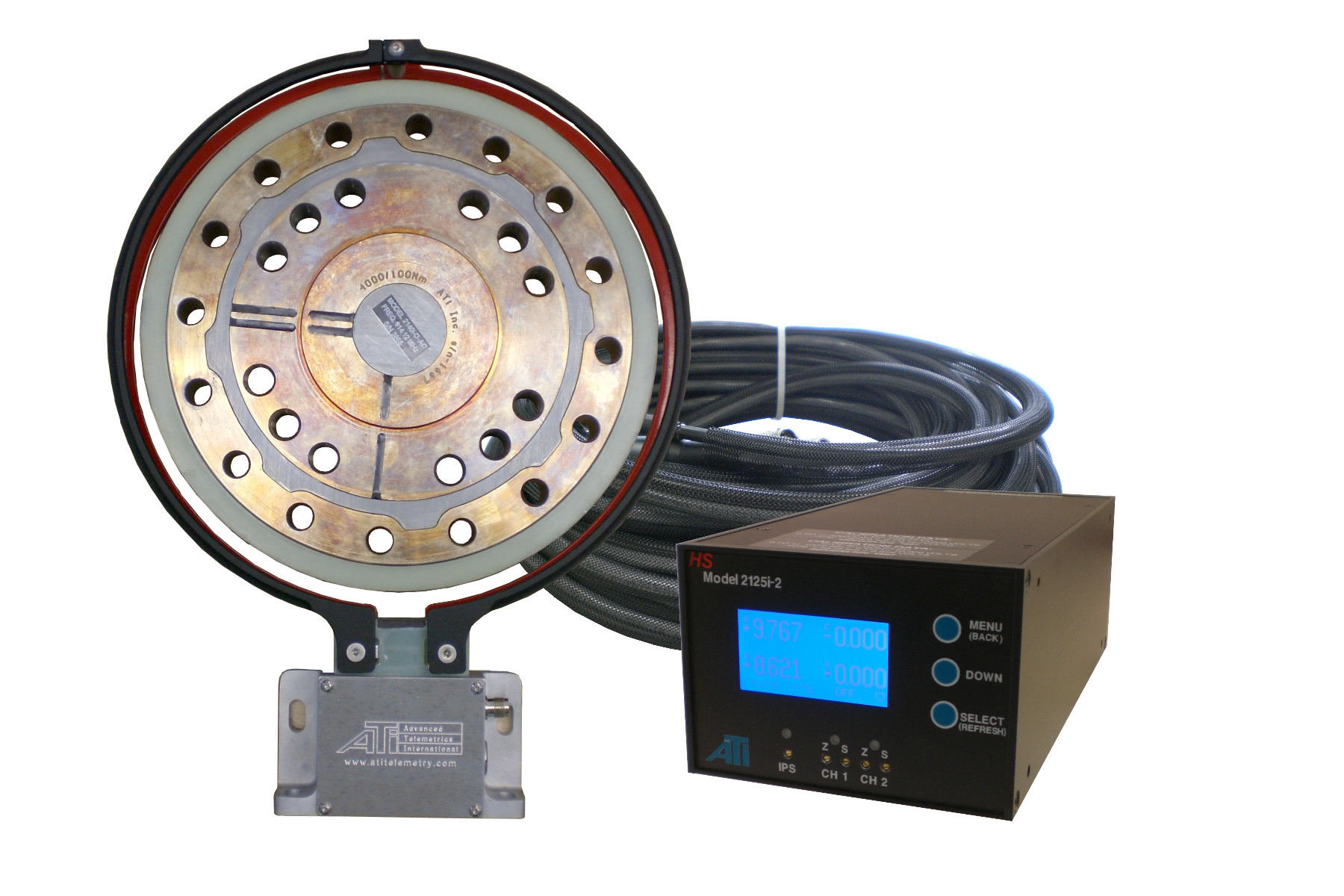

ATI’s Dynamic Torque Sensing System is the practical replacement solution for a conventional rotary torque transducer system. Some of the reasons why are listed below.

Extreme sensitivity. A second dynamic output is available. Which can be set for a full range as low as 1% of the primary output. Thus, output resolution can be as low as 0.0025% of the full primary output range. The secondary dynamic output would also have an overload capability of 500:1. This makes the sensor extremely useful for measuring gear mesh torsional data or extremely small torque fluctuations. This is possible since the data is not corrupted by bearing noise from the sensor.

Highly reliable and durable. RF Telemetry is used for data transfer while Induction Power is used for power transfer to the rotating sensor. These technologies permit excessive movement. Between the rotating sensor and stationary loop antenna with no effect on the signal quality. However, minimal alignment between the stationary and rotating components is required.

Immune to the Environment. The RF Telemetry and Induction Power are also immune to dust and oil build-up.

For more information on Dynamic Torque Sensing System, contact us.

Reviews

There are no reviews yet.