Automated Fuel Management for Diesel-Powered Equipment

The Fuel Supply Automation Unit is designed to automate the fuel transfer process between reserve and main tanks in diesel-powered machinery. This device ensures your critical systems—such as diesel generators, boilers, heaters, and refrigeration units—operate without interruption by maintaining optimal fuel levels automatically. It works in conjunction with fuel level sensors and electric pumps. To deliver efficient, hands-free fuel supply control, reducing the risk of manual error and equipment downtime.

🔧 Key Features of the Fuel Supply Automation Unit:

Automatic Fuel Pump Control:

Monitors the main tank’s fuel level and automatically switches the fuel pump on or off. Based on pre-set minimum and maximum thresholds.Sensor Compatibility:

Works with a range of fuel level sensors. Including DUT-E, DUT-E 2Bio, and DUT-E GSM, providing flexibility for different system setups.Supports 12V and 24V Pumps:

Compatible with both 12V and 24V fuel pumps, making it suitable for a wide range of equipment and installations.Simple Configuration:

Allows easy setup of fuel level thresholds without the need for software or programming skills.Plug-and-Play Installation:

Comes with all necessary components, including interface cables and relays, for fast and straightforward installation.Compact and Durable Design:

Engineered for industrial environments, ensuring long-lasting performance and reliability.

⚙️ Applications of the Fuel Supply Automation Unit:

Diesel Generators:

Keeps generators running continuously by ensuring the main fuel tank is always filled, especially during critical backup operations.Industrial Boilers and Heaters:

Maintains consistent fuel supply for heating systems, improving energy efficiency and preventing downtime.Refrigeration and HVAC Systems (HVAC-R):

Supports uninterrupted cooling and temperature regulation by automating the fuel feed process in fuel-powered units.Off-Grid and Remote Installations:

Ideal for use in locations where manual monitoring is impractical—mines, construction sites, mobile camps, and remote facilities.

How the DUT-E SAU Works

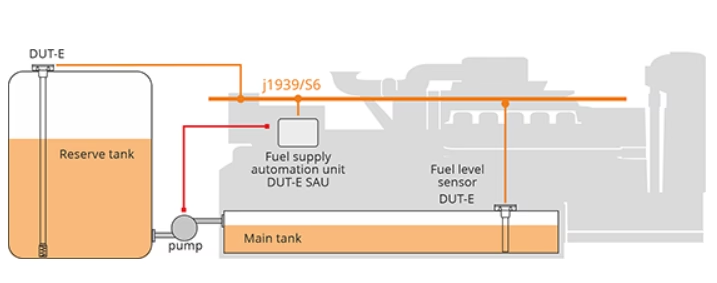

The DUT-E SAU constantly receives fuel level data from a DUT-E fuel level sensor installed in the main tank of a diesel generator.

When the fuel level drops to the pre-set minimum. The DUT-E SAU automatically activates the fuel pump to transfer fuel from the reserve tank. Once the fuel reaches the maximum level, the unit switches the pump off, completing the refuelling cycle. This automated process ensures a consistent fuel supply without manual intervention.

Configuring the Fuel Supply Automation Unit

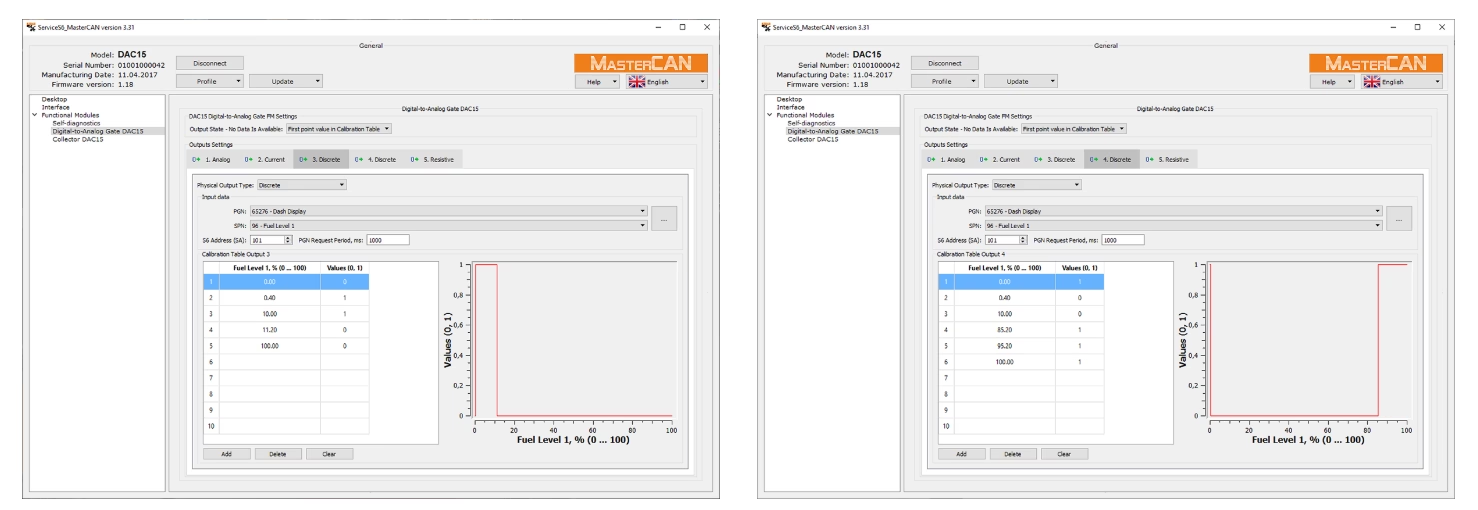

The key settings of the Fuel Supply Automation Unit (DUT-E SAU) are the minimum and maximum fuel levels in the main tank:

The minimum fuel level is the point at which the unit triggers automatic refueling from the reserve tank.

The maximum fuel level is the point where refueling stops, preventing overfilling.

These levels are set as a percentage of the tank’s total volume. So an accurate tank calibration is required before setup. Calibration involves creating a table that maps fuel level (in millimetres) to fuel volume (in litres). Allowing the system to calculate remaining fuel more precisely. The DUT-E fuel level sensor stores the calibration data in its memory, ensuring the automation unit operates with high accuracy.

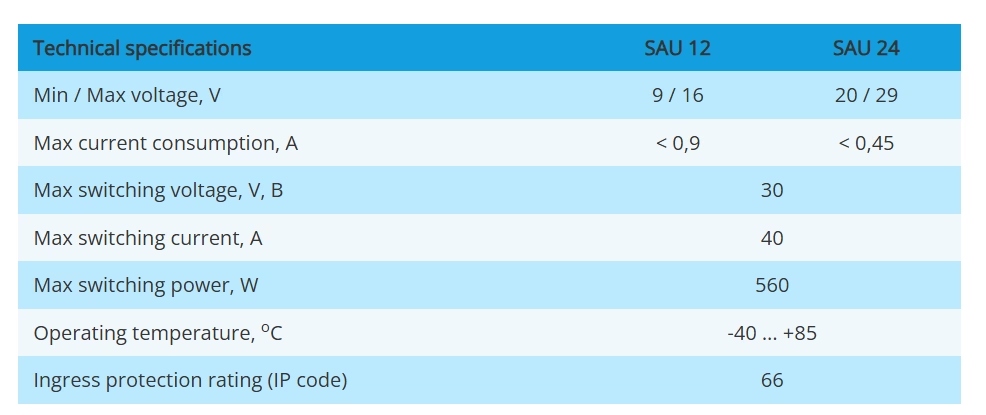

Technical Specifications of the Fuel Supply Automation Unit

For more information, contact us.