The Power Transformer Oil Monitor is called the OilQSens® Model OQ3000 measures components and possible impedances of the oil. Impedance products can be particles, cellulose fibres, acid and moisture. These items can cause a change in the electrical properties of the oil. Dependent parameters measured continuously on-line. Changes in the oil, then the condition of the transformer oil is evaluated.

Firstly, the OilQSens® measures the specific electrical conductivity. Electrical Conductivity of oil is extremely low. Using a compensation algorithm in neural network it accurately measures conductivity to 0.1 picosiemens per metre.

Secondly, it measures the dielectric constant and the oil temperature. Relative permittivity is a measure of the dielectric constant. The oil sensor makes a statement about water ingress and a modification of insulating strength of the oil. Therefore, with the conductivity values, a clear picture emerges of the changes in the oil. As oil ages it forms charge carriers which alter conductivity. The presence of metal catalysts, oxygen and temperature cause the process to be accelerate.

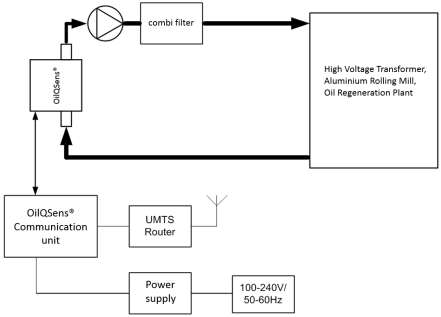

A unique feature of the system is that it provides online monitoring of the loss factor tan delta directly from the transformer. Calculated from the conductivity and permittivity. This online system is ideal for remote locations. Measurements transmitted via LAN, WLAN or Serial Interface.

Features of the Power Transformer Oil Monitor include:

- Condition Based Maintenance providing huge cost savings

- Detects change in the system before damage starts

- Decentralised Web based monitoring system 24/7

- Easy to install and retro-fit

- Low cost of ownership, no service contract and no consumables

To learn more click here for the brochure or contact us