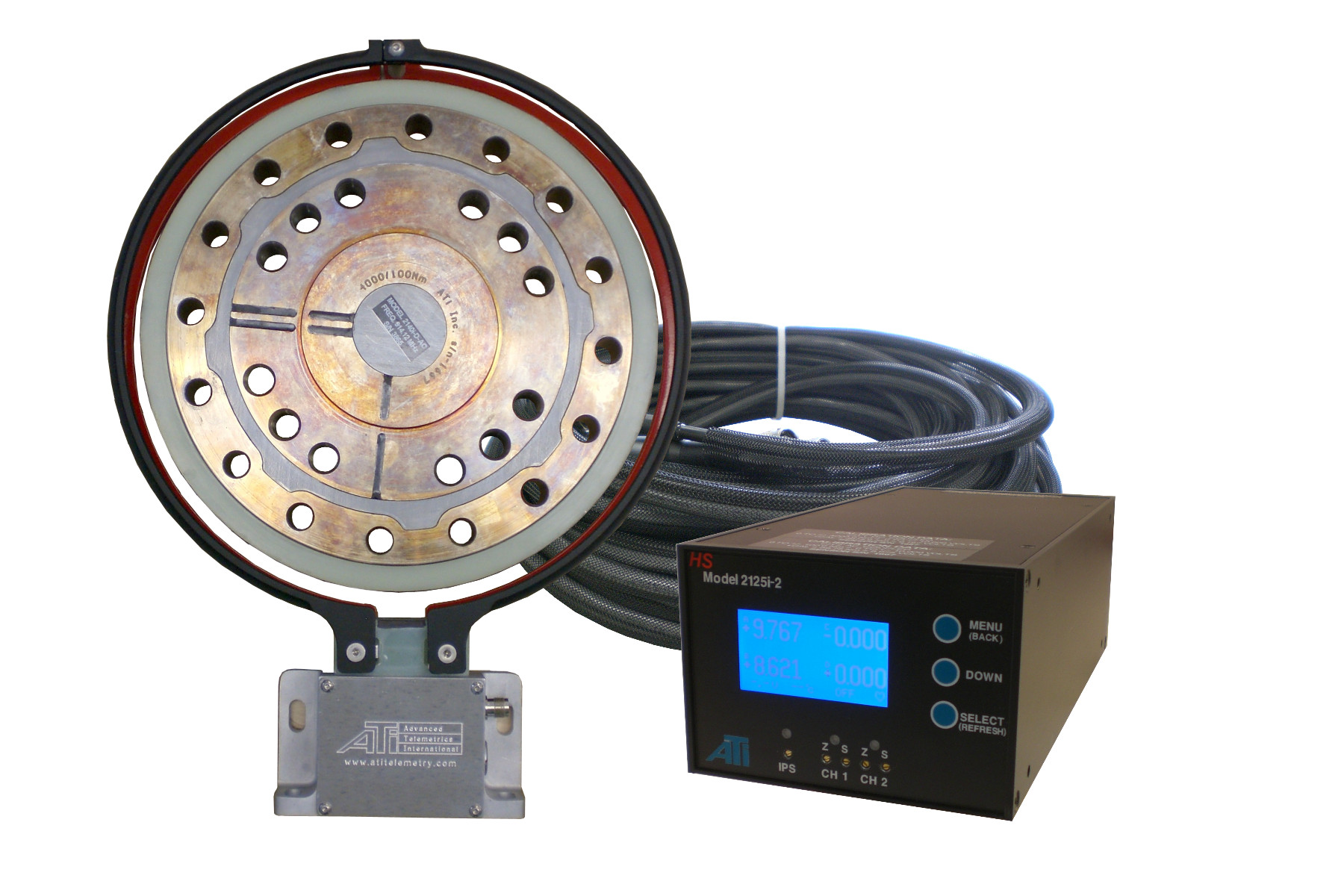

The 2100/3100 Series is a Wireless Torque Sensor System.

Firstly, conventional foot mounted, rotary torque transducers with bearing and slip rings can be impractical. Where they are unable to operate optimally in high speed, vibration and dirty environments.

The 2100/3100 solves this issue by using RF Telemetry. With RF Telemetry, the transfer the data eliminates the need for slip rings. Therefore, making the wireless torque meter more reliable and durable. By using batteries or induction power, power is providing energy to the rotating sensor and transmitter. This allows movement between the rotating sensor and stationary loop antenna with no effect on the signal quality. RF Telemetry and induction power are immune to dust and oil build up. Whereas, infrared torque sensors are sensitive to build up and shaft movements.

Features of the Wireless Torque Sensor System 2100/3100 Series include:

- Torque Sensing System available in Disk, Spline or Flange Mounting

- Dual Range Option available

- High speed operation with no lubrication up to 50,000 RPM

- Non Contact – no bearings or foot mounting

- Short sensor length minuses coupling accuracy requirement

- Suitable for any size shaft

- Eliminates frictional error due to bearings

- High Torsional Stiffness

- No Slip Ring Noise or Maintenance

Contact us for more information.

Reviews

There are no reviews yet.