Rotor Balancing

Firstly, Rotor Balancing is the process eliminating unbalance and vibrations in rotating machinery. Secondly, Balanced Rotors are essential for smooth operation, reduced material defects and a longer machine life. It is a preventative machinery diagnostics tool. Finally, it will reduce long down times of machinery and make it more efficient.

Rigid Rotors

In most cases, rotors are considered “rigid rotors”. Because the operating speed of the machine is below 70% of its first resonance frequency. Resonance Frequency is the critical speed, where structural resonances cause heavy vibrations. Plus at the resonance, the phase is turning quickly and it would be impossible to make the correct measurement.

How do you balance a Rotor?

First off you will require:

- Dewesoft Data Acquisition System for Vibration Analysis

- DewesoftX3 Data Acquisition Software (FREE with Dewesoft Data Acquisition System) comes with inbuilt balancing module

- Counterweights

- Precise Vibration Sensors

Step by Step guide to balancing a rotor

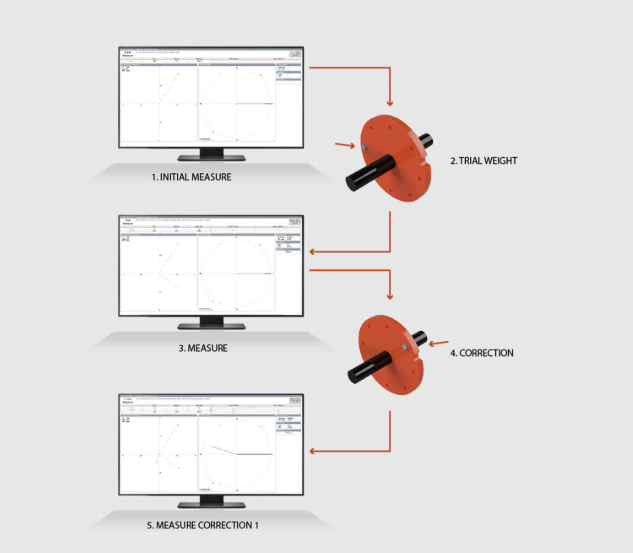

- Firstly, record the actual status

- Secondly, add a trial weight

- Thirdly, record with trial weight

- Plus, add the correction weight at the appropriate angle

- Finally, record with corrected weight & angle

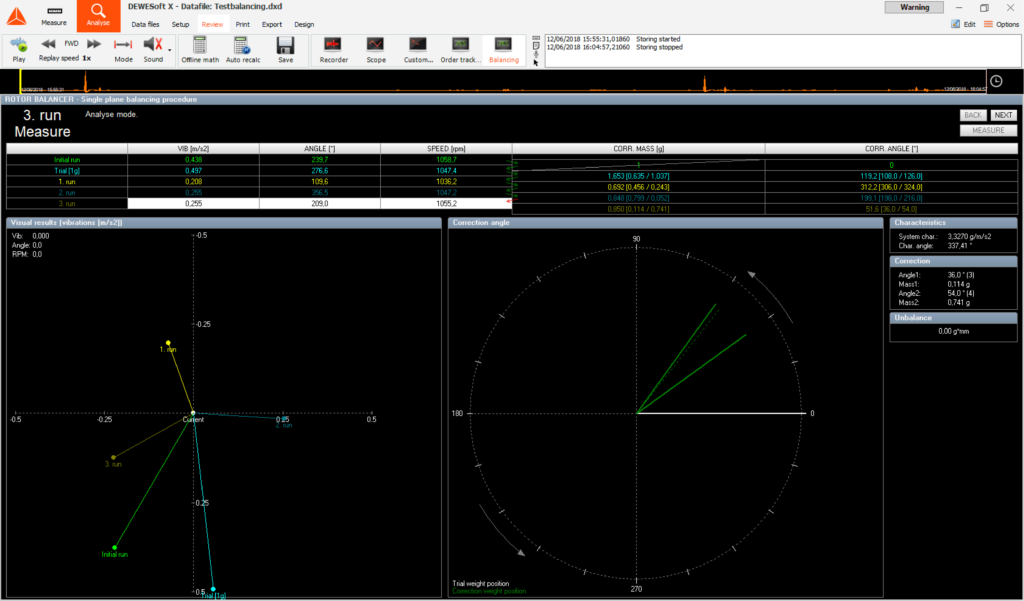

Steps can be repeated if you require. However, in the software, you can see the current step with an explanation with which action has to be taken. To the right, there are interactive buttons such as “Back”, “Next”, “Measure”. The software will automatically fill the table with the results after each step. The polar plot shows the vibration levels (amplitude and angle) of each run. However, the unit depends on the input, mm/s or mm/s² or g to be entered first.

Which one Single Plane Balancing or Dual Plane Balancing?

Depending on the machinery, single or dual plane balancing is required. Selecting one plane or two plane balancing generally requires on two factors:

- The ratio of the length of the rotor to the diametre of the rotor

- Operating speed of the rotor

Other features of the Dewesoft X3 Software to assist with Rotor Balancing

Auto generated Measurement Screen

When you have set up the balancing module in channel set up, there is an automatically generated display called “Balancing” in Measure mode. This is the rotor balancer visual control, with channels automatically assigned from the math module.

Weight Splitting

If you rotor has a certain number of slots or holes where weights can be mounted, know the position number and split weights instead of the absolute angle. Also, this can be done in the software by selecting “Divide plane xx to xx” from properties.

Link Multiple Instances

If the amplitude and phase of the signal are not stable, find a different location for the mounting sensor to get a better signal. Otherwise mount multiple sensors and measure them at once, and then decide which signal to take. The whole procedure is the same. However, you only need to operate one visual control as all other instruments will follow providing different results.

Initialise with system characteristics

If balancing is done on a particular rotor then the system characteristic is known; a trial weight run is not necessary to do again. System characteristics paremeters may be entered manually. This will allow the correction mass to be calculated immediately. This could be used if a shaft is balanced multiple times at a certain interval. System characteristics describe the relation between mass and vibration.

Where do you buy your Rotor Balancing Equipment from?

Dewesoft design and manufacture versatile and robust data acquisition systems and powerful data acquisition software. Their instruments are easy and fun to use. Modular and extendable and can work with any signal and sensor. They are the ultimate tools for every test and measurement engineer.

Metromatics provides the perfect sales, service and support for Dewesoft’s products in Australia and New Zealand.

For more information on how a Dewesoft System and Software could solve your rotating machinery problems, contact us now.

This content on Rotor Balancing was sourced from our Supplier Dewesoft’s Website www.dewesoft.com