Transient Recorder Programming

The Transient Recorder Channel and system parameters are programmed by high level instructions written to the Ethernet interface or by PI580 Windows application software. Operating parameters are stored in non-volatile memory and automatically loaded when the system is powered up or reset. Data recorders may be programmed in place or configured and programmed prior to fielding.

Programmable channel parameters are input configuration, excitation, calibration modes and levels, gain, and filter frequency. Sample rates, number of pre and post-trigger samples, trigger level and delay, power mode and autostart sequence are programmed by groups of three channels in the 5871 or two eight channel groups in the 5872. Operating parameters can be read back to verify system programming and configuration.

Installation of the Transient Recorder

Data recorders are ruggedised and battery powered. This allows installation near the measurement site to keep input cables short preserving higher signal frequencies. Hardware is available for mounting in 19-inch frames or enclosures.

The 5871 and 5881/3 have self-contained rechargeable batteries. A line operated power supply is available for operating and charging the battery. The 5872 and 5882 require an external battery or other power source. The 5893 is a DC-UPS that provides power from the AC line. It automatically switches to battery. Programmable power modes conserve battery power when setting up or waiting for a test.

Controlling the Transient Recorder

Sample timing and data recording is controlled by a PCM encoded control bus distributed from the Control Module to each Data Recorder. The Command Module has TTL inputs for system control including Clock, Start, Trigger and Autostart. The encoding of control signals makes the system immune to noise on the control bus that could cause false triggering and loss of data. The control bus synchronizes data recorded across multiple recorders.

The 5881 and 5882 Command Modules employ Category 5 cable for recorders within 50 meters of the Command Module. The 5883 Command Module employs optic cable for distances up to 1 kM.

Features of the Transient Recorder:

- Records fast events, up to 10MS/s

- One pre-trigger and two post-trigger sample rates

- 3 or 16 channel battery operated enclosures

- Up to 50 Gs shock

- Ethernet interface with Windows Software

- Dual Inputs, Bridge and ICP

- Programmable for 1/4, ½, and full bridges

- Voltage and Shunt Calibration

- Automatic hands off operation

- Optional Analogue Output for external recording

Transient Recorder Systems consists of:

| Enclosures | I/O Modules | PI580 Software |

|  |  |

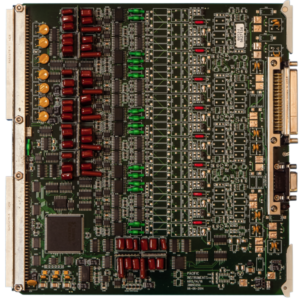

| I/O Modules have high bandwidth dual mode (Bridge and ICP/IEPE) signal conditioning

| PI580 is the turnkey application software for the Series 5800 Transient Recorder System. Operates in Windows Environment Includes everything for system set up – calibration, data display, debrief, and export for post processing |

For more information on the Series 5800, contact us.