This blog on Delivering AI Embedded Computers quickly originally comes from our friends USA based Crystal Group, Inc. Technology leaders in rugged computer hardware, specialising in the design and manufacture of custom and commercial rugged servers, embedded computing, networking devices, displays, and data storage for high reliability in harsh environments.

In this blog, Crystal discusses expanding their engineering team to include a specialist group called “Advanced Program Pursuits” (APP). The APP team are responsible for prototype design and development. This blog is how they go about their jobs, liaising with customers, developing, and testing products in house to deliver a prototype on a tight schedule.

Metromatics proudly sell and provide local support for the Crystal Group product line in Australia and New Zealand.

Delivering AI Embedded Computers on Short Time Frame

In 2022, Crystal expanded their engineering department by adding the Advanced Program Pursuits (APP) team. Firstly, the APP team is responsible for the design and development of prototypes. However, more particularly those prototypes that have unique features or have a tight delivery schedule.

The Customer Requirements

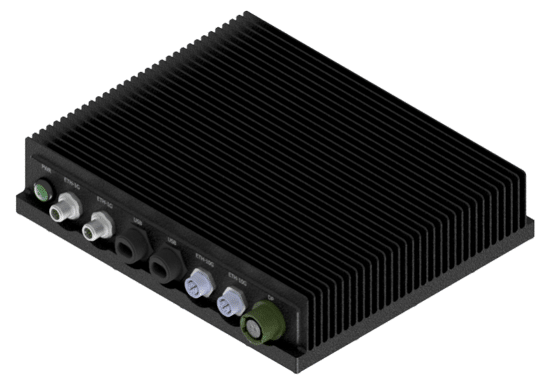

Early on, the first customer approached the team about a project requirement for a Defence application. Yet, the hardware requirements were brief. It had to be small. It had to incorporate the next generation of embedded GPU and it had to be delivered in six months. The RE3500, a rugged small form factor embedded computer was born. Designed to create operator situational awareness using AI.

Secondly, the Crystal APP Team were up for the challenge! This task was sure to test them – a new design, a new build, and a new team. Additionally, they quickly figured out how to work together and establish a functional rapid prototyping process. By communicating consistently with the customer, they were able to design the perfect device. Communication was the key in determining the features and requirements that were important to the project.

One of the challenges was the RE3500 would be operating in an amphibious environment. Therefore, would need to be sealed. In their in-house CNC shop, the APP team developed a custom machined chassis. It delivered in size requirements, kept water out and prevented shock when used in areas exposed to water.

Another challenge was it had to process massive amounts of data. Especially when out in the field used for applications such as image segmentation or object detection. Therefore, optimised I/O was installed so that signal processing in these applications would be reliable.

In-house Resources a great advantage for Rapid Prototyping

A great advantage Crystal Group was able to offer was the ability to use in-house resources. Such as their CNC shop and MIL-STD testing labs. This reduced the delivery and testing times to enable the meeting of the products six-month deadlines. Therefore, integration occurred successfully.

Finally, learn more about Crystal’s product range or contact us to find out how Metromatics and Crystal Group can customise a solution that’s right for you.