This application note on Load Sharing with Pump Controller is courtesy of our friends, Acromag. Should you require any further information on this application, contact us.

The Problem

A local Public Utility District has a freshwater collection tank that sometimes fills rapidly and other times slowly. At times the main pump can not keep up. The backup pump must be turned on to keep up with the incoming water. The problem is that with the primary pump (running most of the time), has a higher failure rate and maintenance costs.

The Solution

Find a way to share the load between the two pumps.

Implementing the Load Sharing with Pump Controller

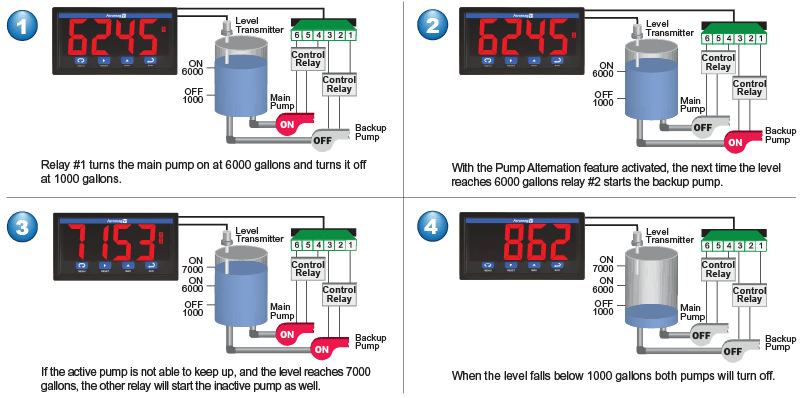

The VPM3000 can be used as a low-cost pump controller when paired with a continuous level transmitter. Either by controlling one pump for filling and another for draining or as in this case, two for draining. The VPM3000 has a useful feature of being able to control and alternate between two pumps. In this case, the goal is to control the level between 1,000 and 6,000 gallons. The first or main pump turns on when the level reaches 6,000 gallons and pumps down to 1,000 gallons and then shuts off. The next cycle, the second or backup pump turns on at 6,000 gallons and shuts off at 1,000 gallons thereby distributing the pumping load more effectively. If at any time the active pump cannot keep the level below 7,000 gallons, the inactive pump is turned on also.

Product Used

VPM3000 Programmable Digital Panel Meter with Alarm.

How did Acromag solve the problem?

In conclusion, Acromag solved the Load Sharing on the Pump Controller application by implementing the VPM3000 Digital Panel Meter. The unique combination of features available on the VPM3000 allowed the customer a low-cost solution without having to invest in an expensive and complicated controller. The VPM3000 is easily configured through the front panel pushbuttons or the free DisplayWizard™ software. Therefore, no need for complicated PLC programming.