This application summary has been provided by our valued supplier FUTEK.

Application Summary of Oktoberfest Fermentation Tank Measurement

Perfecting a good beer takes equal parts of great grains, as well as great equipment. Fermentation vessels are integral in the outcome of beer’s taste, colour, and alcohol content. Load cells are used to do the tank measurement of the contents throughout the brewing process.

Products in Use

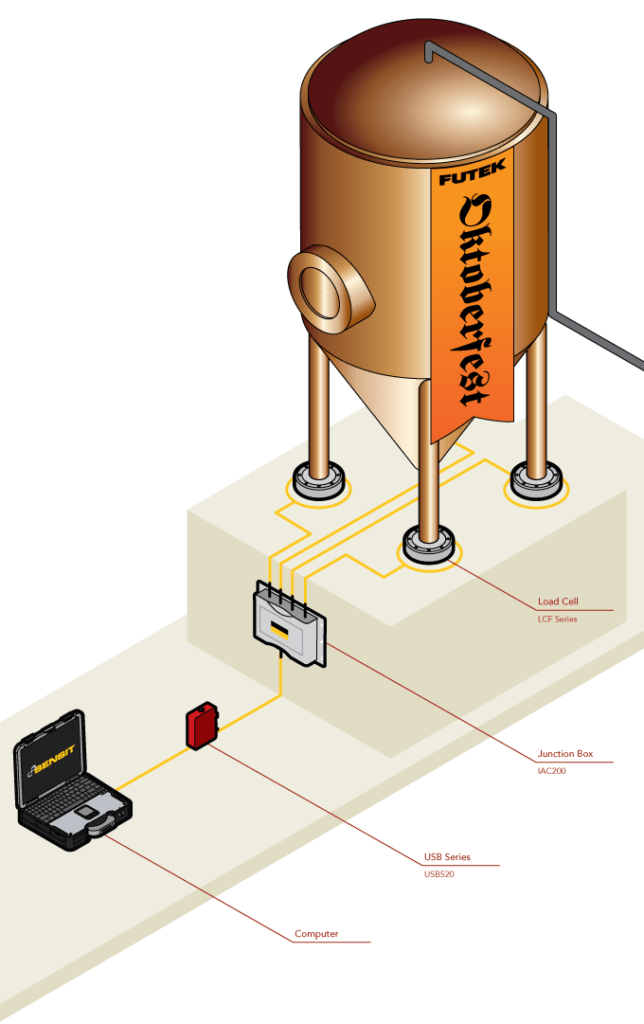

Four Pancake Load Cells (LCF Family) paired with Instrumentation (IAC200 and USB520)

How it Works

- In commercial breweries, the contents of fermentation tanks (vessels) need to be accurately gaged throughout it’s brewing period. These breweries tend to use load cells at the base of their tanks to monitor these measurements.

- In this depiction, four LCF Family Pancake Load Cells were installed at the base of each of the tank’s posts.

- After the fermentation process concludes, the brewers will need to drain the tank to proceed with packaging the beer.

- As this occurs, a carefully siphoned amount of liquid leaves the tank. This measurement is monitored by the LCF load cells and passed to a 2–4 Channel Summing Junction Box (IAC200).

- The summing junction box averages the beer’s emptying rate from the tank and streams that to the USB520, which can display the data on a PC.

All FUTEK application illustrations are strictly conceptual. Contact us for more information.