This application note on Pressure Monitoring in Hybrid Rocket Engines comes from our friends at FUTEK.

Why Pressure Monitoring is Critical in Hybrid Rocket Engines

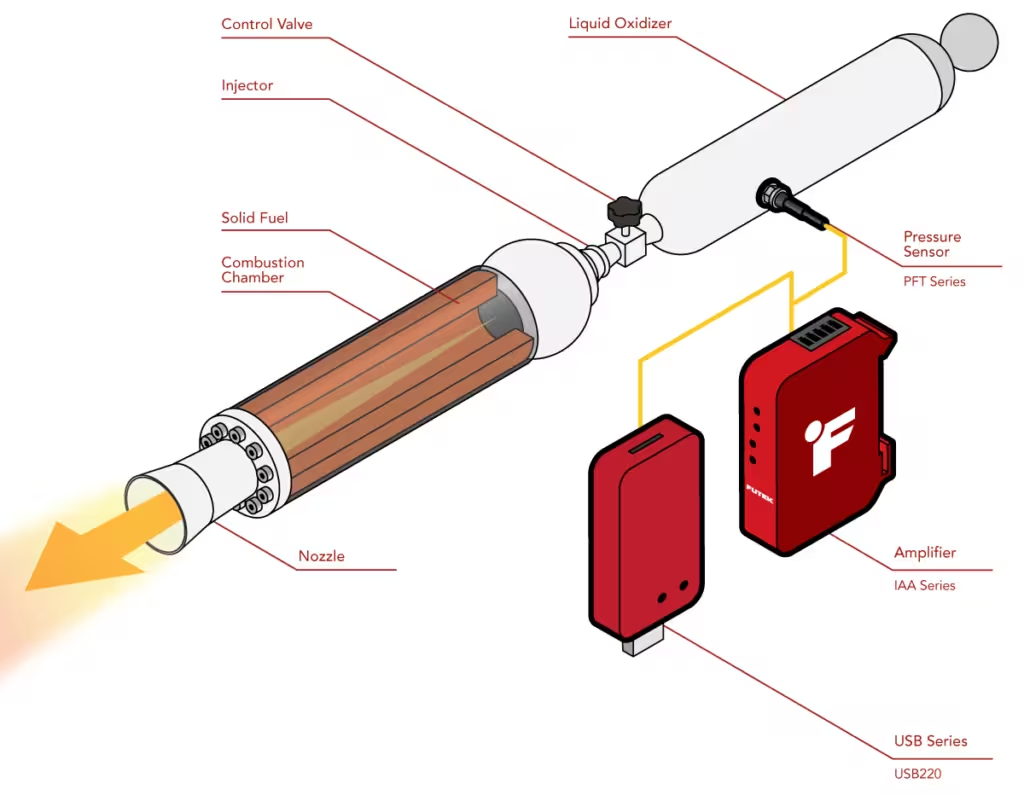

Pressure monitoring is a critical aspect of hybrid rocket engine design, ensuring safety and optimising performance. Hybrid rocket engines, which use a combination of gaseous and liquid fuels, are susceptible to rapid pressure spikes that, if unmonitored, could lead to catastrophic failure. Implementing high-frequency pressure sensors, such as the FUTEK PFT510 series, allows real-time monitoring and control, ensuring mission success.

In addition, pressure monitoring provides valuable feedback on engine performance. Enabling system optimisation and efficiency improvements.

While most pressure sensors on the market are limited to a natural frequency of 1kHz. The PFT510 series sets itself apart. As it features natural frequencies ranging from 6kHz to 100kHz. This higher bandwidth enables real-time tracking of rapid pressure changes. Hereby, offering unparalleled precision in hybrid rocket engine monitoring.

How FUTEK’s PFT510 Sensor Provides High-Frequency Monitoring

The PFT Series pressure sensor is designed to be mounted flush with the oxidizer tank’s inner walls. Therefore, ensuring accurate pressure measurement during engine operation.

Integration with DAQ Systems and Software

Real-time high frequency pressure data is collected by the sensor and can be streamed and logged using the USB530 to a PC running SENSIT software. Alternatively, the sensor can be connected to a PLC or DAQ system via the IAA300, providing flexible integration into existing test setups.

FUTEK Sensors Available in Australia and New Zealand

- FUTEK Miniature Flush Mount Pressure Sensor (PFT Series): High-frequency pressure monitoring

- IAA300 High Bandwidth Instrumentation: Signal amplification and data transmission

- USB530: PC interface for logging and monitoring via SENSIT software

- USB220: High resolution USB Solution

Interested in high-precision pressure monitoring solutions? Contact Metromatics today to learn more about FUTEK’s advanced sensor technology in Australia and New Zealand.

About FUTEK

FUTEK specialises in the design and manufacture of high-precision sensors. Specifically focusing on load cells, torque sensors, pressure sensors, and multi-axis sensors. They also develop amplifiers, instrumentation, and software to complement their sensor products. FUTEK’s sensors are known for their accuracy and reliability. In addition, they are used in a variety of industries including aerospace, medical devices, robotics, automotive, and industrial automation.

FUTEK’s expertise extends to providing custom sensor solutions for unique applications. Also they are widely recognised for their work in the space industry. For example, their sensors have been used in high-profile projects like NASA’s Mars Rover missions. Their SENSIT software enables real-time data acquisition and analysis, further enhancing the integration and use of their sensors in advanced systems.

Their products are widely used in applications requiring precise measurement and control, including testing and quality control in R&D labs, as well as in-field operations.

Metromatics sell and support the FUTEK product range to customers in Australia and New Zealand.