Fuel Flow Measurement Redefined: The DFM Marine Flow Meter for Heavy Machinery

The DFM Marine is a high-precision fuel flow meter. Designed to monitor fuel consumption and engine operating time in heavy-duty applications. Whether it’s for sea and river vessels, locomotives, mining equipment, or powerful diesel generators. The DFM Marine helps reduce fuel waste, detect inefficiencies, and improve overall operational performance.

Key Features

Built Tough for Demanding Conditions

The DFM Marine features a corrosion-resistant brass measuring chamber. In addition, the choice of durable duralumin or solid brass body construction. Therefore, providing long service life in harsh environments.Flexible Installation Options

Available with threaded or flanged fuel line connections to suit a wide variety of fuel systems.Handles High Fuel Temperatures

Suitable for monitoring liquids up to 150°C, ideal for engines and equipment operating in high-temperature conditions.Dual-Line Differential Measurement

Easily set up two meters in a paired configuration to monitor both fuel supply and return lines without the need for separate calibration.Advanced Operating Time Tracking

Tracks engine time in multiple load modes—such as “Idling,” “Optimal,” and “Overload”—providing insight into equipment performance and fuel efficiency.Security and Tamper Alerts

Built-in diagnostics help detect interference or tampering with counters for enhanced reliability and accountability.ABS Certified

Certified by the American Bureau of Shipping for use in marine and offshore applications.

Applications

Marine & River Vessels – Monitor real-time fuel consumption and engine health on board.

Locomotives & Rail Vehicles – Improve fleet fuel usage tracking and maintenance scheduling.

Mining & Quarrying Equipment – Optimise fuel costs for large machines operating in remote or rugged environments.

Diesel Generators & Industrial Boilers – Ensure efficient fuel use in high-power stationary systems.

Why Choose DFM Marine?

With rugged construction, flexible installation, and intelligent data tracking, the DFM Marine helps businesses manage fuel more effectively, reduce costs, and extend the life of their machinery. It’s the smart choice for operators who demand accuracy, durability, and real-world performance.

How it Operates

Positioned past the fine filter in the fuel line, the DFM Marine operates as a direct volumetric fuel measurement device, housing a unique ring-type measuring chamber. As the fuel pressure drives through the flow meter inlet, the ring traverses along the chamber’s inner surface, pushing the fluid out systematically. For each complete ring rotation, a volume equivalent to the chamber’s capacity is pushed out. Volume is automatically calculated by the flow meter’s electronic unit.

Integrate your results seamlessly with Fuel Monitoring, GPS Fleet, or Telematics Monitoring Systems. This synergy provides real-time data insights and live t p conditions (t p = temperature and pressure). Therefore, making it a pivotal tool for informed decision-making.

Key Insights Delivered:

- Fuel Consumption Metrics: Gain insights into instant fuel consumption rates, hourly fuel consumption, overall consumption, and consumption during different engine modes.

- Operational Analysis: Track the total operational hours, differentiating between modes like “Idling”, “Overload”, and “Optimal”. Plus, reset counters as needed.

- Special Features: In addition, dive deep with insights into “Tampering” and “Interference” modes, current engine operation status based on consumption, fuel temperature, battery charge, and more.

- Diagnostics Function: Assess the flow meter’s performance, adapt settings to fuel system parameters, and access diagnostic codes and event logs for a holistic view.

Finally, enhance your experience further with the Service S6 DFM Software for PCs. Enabling you to tweak settings for units of measurement, operational mode boundaries, and temperature correction coefficients.

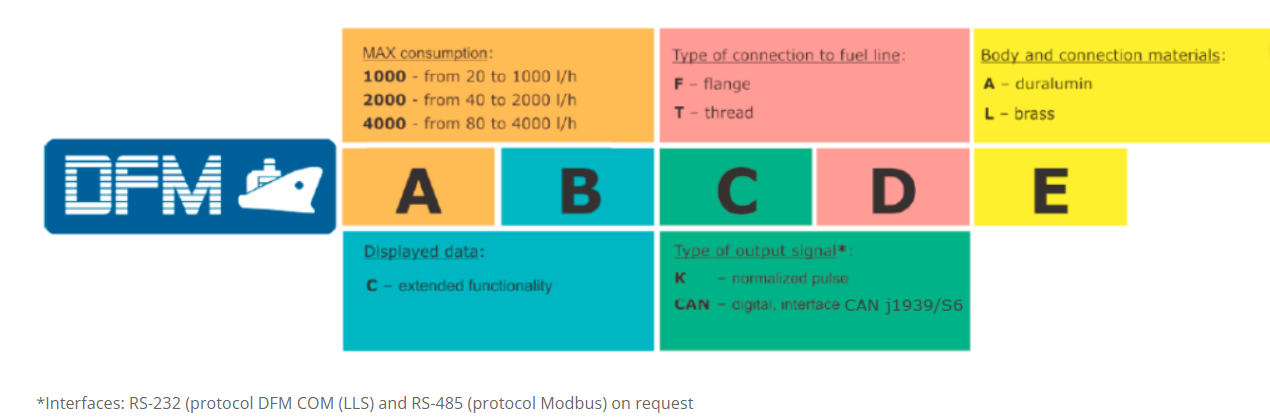

DFM Marine Models

The DFM 2000 allows measurement of consumption from 40 to 2,000 litres per hour. See below other model options.

DFM Marine Flow Meter Design

Finally, harness the power of precision with the DFM Marine Flow Meter for heavy machinery. Elevate your operational insights and optimise fuel consumption like never before. Don’t wait, enquire today by contacting us!

Specifications

| Specifications | Result |

|---|---|

| Maximum Pressure | |

| Flange Connection | 25 atm |

| Thread Connection | 16 atm |

| Maximum Temperature of Working Fluid | 95°C to 150°C* |

| Fluid Viscosity | 1.5 - 6.0mm ²/S. (CST) |

| Measurement Chamber Material | Brass |

| Body/Connection Materials | Brass/Duralumin ** |

| Inaccuracy Rate | See Measurement and Accuracy Table below for |

| Communications Standard | CAN J1939/S6 + NMEA2000 Digital Interface. RS232/485 (Protocols: Modbus and DFM COM (extended LLS) Interfaces pulse output |

*Under the order

** Specified in the order

Measurement and Accuracy

| DFM Marine 1000 | |

|---|---|

| Starting flow rate* m³/h | 0.01 |

| Minimum flow rate (Qmin) m³/h | 0.02 |

| Maximum flow rate (Qmax) m³/h | 1 |

| Relative Accuracy Error % not more than *** | ±0.5** |

| DFM Marine 2000 | |

| Starting flow rate* m³/h | 0.02 |

| Minimum flow rate (Qmin) m³/h | 0.04 |

| Maximum flow rate (Qmax) m³/h | 2 |

| Relative Accuracy Error % not more than *** | ±0.5** |

| DFM Marine 4000 | |

| Starting flow rate* m³/h | 0.04 |

| Minimum flow rate (Qmin) m³/h | 0.08 |

| Maximum flow rate (Qmax) m³/h | 4 |

| Relative Accuracy Error % not more than *** | ±0.5** |

- *Minimum threshold flow rate value when the meter starts operating. The value is indicated for reference only. Therefore, accuracy is not standardised for operation on the starting flow rate.

- **In differential/summarisation measurement mode, in accuracy is not higher than ±1.0% (depending on the proportion of fuel consumption in the chamber of each flow meter used)

- *** If fuel consumption in the range from Qmin to e-Qmin, the allowed inaccuracy is not more than ±1.0% . Therefore, for differential/summarisation fuel consumption modes – not more than ±2.0%

Installation Options

The DFM Marine fuel flow meter is installed directly in the fuel line after the fine fuel filter. It can be configured in one of two common installation schemes:

Pressure Side Installation – positioned after the low-pressure pump

Suction Side Installation – positioned before the low-pressure pump

For full installation guidance, including diagrams and setup instructions, please refer to the DFM Marine Operational Manual.

Power Supply Options

Stand-Alone Power Supply (DFM Marine C Models)

These models are powered by an internal lithium-silicon battery. The estimated operating time before full battery discharge is at least 36 months, ensuring long-term, maintenance-free operation.

Combined Power Supply (DFM Marine CK/CCAN Models)

These models operate using an external power source, with a built-in battery as backup in the event of external power loss. If the external voltage drops below 8V, the unit automatically switches to battery mode. In this mode, the estimated operational time is also at least 36 months.

Reviews

There are no reviews yet.