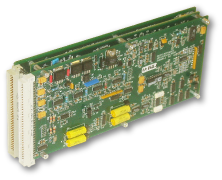

After acquiring data, the Transient Recording I/O Modules digitise and record it into non-volatile, solid-state memory. In addition to this, these modules also record calibration, pre-trigger and post-trigger data. Furthermore, in a typical test scenario a TTL input, program instruction or automatic sequencer initiates the recording of pre-trigger data. Following this, a TTL input or on-board discriminator then triggers post trigger data recording.

The quantities and sample rates of pre and post-trigger data storage are programmable. As a result, this configures the transient recorder according to the characteristics of the collected data. Furthermore, users can also change sample rates during acquisition without interrupting data flow to capture high-speed events while maintaining sufficient memory space to record long-term effects. The 5800 is also configurable with multiple records. For example, each use the same pre and post-trigger sampling profile. Finally, an ethernet interface debriefs and transfers data into permanent storage.

Each channel has two inputs: one for bridges, voltage, RTDs, potentiometers and thermocouples; the other AC coupled with current excitation for transducers with built-in electronics. Signal conditioning includes programmable excitation and completion for 1/4, 1/2 and full bridge, AC-coupling, automatic balance, voltage and four-step shunt calibration, programmable gain and a four frequency, eight-pole filter.

Key Features of the Transient Recording I/O Modules:

- Record fast events, up to 10 MS/s

- One pre-trigger and two post-trigger sample rates

- Rugged 3 or 16 channel, battery operated enclosures

- 16 Channel A/C powered laboratory enclosures

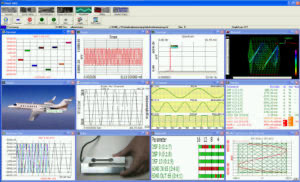

- Ethernet interface with Windows software

- Dual inputs, bridge and ICP

- Programmable for 1/4, 1/2 and full bridges

- Voltage & shunt calibration

- Automatic, hands-off operation

- Analog output for external recording

For more information, please contact us.