This application note on remote monitoring Steam Well for Power Generation has been provided by our supplier Acromag.

Defining the problem on Remote Monitoring Steam Well

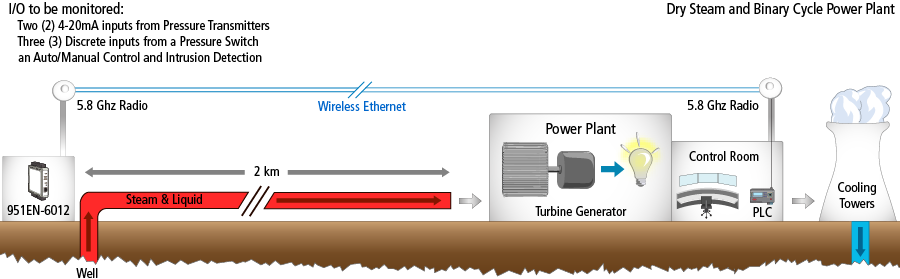

Operations at a remote geothermal steam well are monitored by a PLC from the power plant. Therefore, personnel need to transmit conditions from the wellsite to the control room 2km away. Apparently, a wireless communications network is available for Ethernet remote I/O. Furthermore, modules can be installed at the wellsite for telemetry purposes.

System Requirements

Remote communication via a 951EN-6012 Ethernet/IP module to an Allen-Bradley CompactLogix™ PLC. They need to monitor three discrete inputs and two analogue inputs. One Acromag® 951EN-6012 combination I/O module will accept these five inputs and report over the wireless network back to the PLC.

Featured Products

951EN-6012: Ethernet/IP Combo Module, 4 current inputs, 2 current outputs, 6 discrete I/O

Implementing the Solution

Firstly, refer to the Acromag CompactLogix™ application note, the RSLogix™ 5000 software can be configured to discover the I/O module. An EDS file is available on Acromag’s website from the 951EN-6012 product page, to create the module profile.

Secondly, the 951EN-6012 Ethernet/IP Control and Information Protocol (CIP™) module communicates with explicit messaging. So reading and writing is done with the Register Map using Object Models. The Acromag product user manual lists all of the CIP service definitions and formats.

Thirdly, the I/O module is configured using any standard web browser. The module is password protected for added security. Enter the network parameters and select the analog I/O ranges.

Fourthly, with wiring and power applied, view the analogue and discrete test pages in the browser to validate operations. For reliable performance, apply earth ground as shown in the Acromag user manual.

Above all, for further information on this application, contact us.