This application note has been provided by our valued supplier Acromag.

Defining the Problem of Splitting Gas Detector Outputs for Monitoring & Process Control:

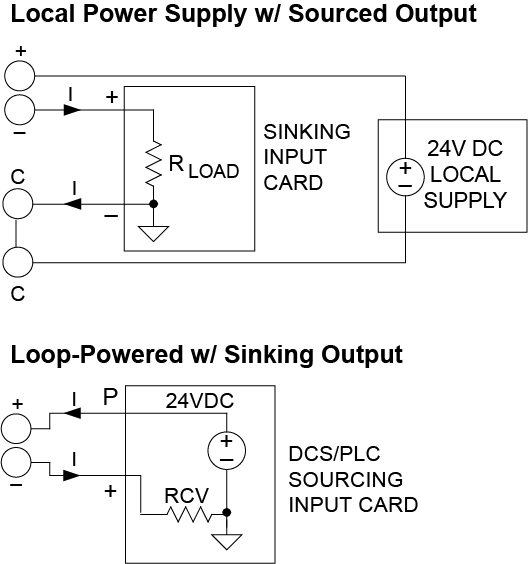

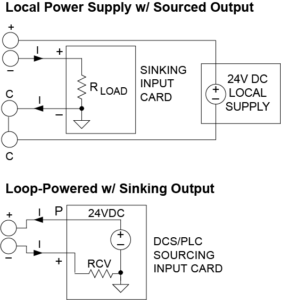

Methane (CH4) and Hydrogen Sulfide (H2S) are monitored with MSA X5000 Gas Monitors at a remote wastewater pumping station. The 4-20mA outputs must be split to a GasCard XL Controller and Emerson Ovation I/O. The Controller has powered inputs. However, the Ovation inputs require an external power source. Typical splitters have 2 outputs that are identically powered: either both are sinking or both are sourcing. Hence, we need a splitter with independent outputs to interface with our instrumentation.

System Requirements:

The SP family of splitters can be powered by any low voltage DC supply, 9-32V. Loop powered models include 2 independent and isolated outputs that can be wired as either sinking or sourcing to the loads. USB configuration via the Acromag Agility mobile application for Android devices or with a Windows PC.

Agility Mobile Application

Output Wiring

Implementing the solution

- Download the Agillity mobile application from the Google Play Store or Windows software from Acromag.

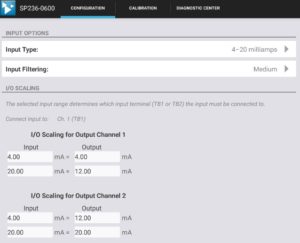

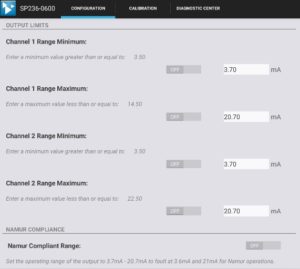

- Configure the module. Scale the input and output ranges independently for normal or reverse acting outputs. Add programmable output clamps or Namur compliant limits if needed.

- Wire each output for sinking or sourcing power to the load.

- Review manual to apply earth ground for best practice wiring.

Why Acromag?

Therefore, one splitter module eliminates having two separate modules that would increase the wiring and cost. Additionally, the SP products have UL/cUL Class 1 Div 2 & ATEX Zone 2 approvals, 4G Vibration, 25G shock ratings and can operate from -40 to 80°C temperatures.

For more information about splitting gas detector outputs, contact us.