In modern manufacturing environments, robotic arms play a vital role in improving productivity by automating repetitive and complex tasks around the clock. These robotic systems are not only programmable but can also function collaboratively as co-robots (cobots), working safely alongside humans.

To ensure accurate, stable, and controlled movement, robotic joints—driven by servo or stepper motors—must not only monitor position but also torque output. By integrating reaction torque sensors, engineers can develop feedback-based control loops that enable smooth, consistent, and autonomous operation.

🛠️ Products in Use

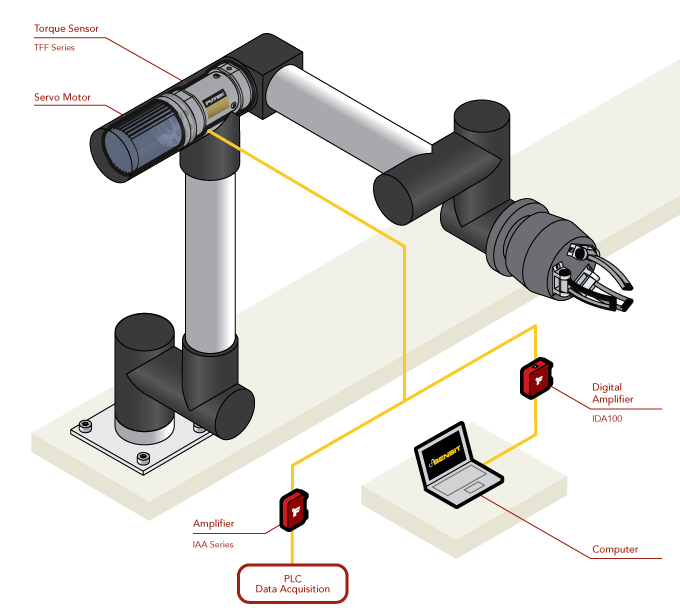

For this application, FUTEK provides the following solutions:

- TFF400 Reaction Torque Sensor

- IAA Series or IDA100 Amplifiers

These components form a reliable system for joint torque feedback and motor control.

🔁 How Robot Joint Control with Torque Sensors Works

- Sensor Installation

The TFF Series Reaction Torque Sensor is mounted between the servo motor and the robot arm’s frame or mounting points. - Torque Measurement and Signal Amplification

As the motor operates, the torque produced is measured by the TFF sensor. This raw signal is then amplified using FUTEK’s IAA Series or IDA100 signal conditioners. - Feedback to Control System

The amplified torque signal is sent to a PLC or robotic controller, where it helps close the control loop. This enables dynamic adjustments in real time for smoother, more precise joint motion. - Optional Monitoring and Software Control

For enhanced performance and diagnostics, the signal can be monitored using FUTEK’s SENSIT™ software, which provides real-time visualisation and digital calibration options.

⚙️ Why Torque Feedback is Essential

- Ensures smooth and precise joint movement

- Prevents over-torque conditions and wear

- Supports advanced robotic functions like force-limited collaboration in cobots

- Enables adaptive responses in dynamic environments

About FUTEK Advanced Sensor Technology

Founded in 1985, FUTEK is a global leader in the design and manufacture of advanced sensors and test instrumentation, offering:

- Load cells, torque sensors, pressure sensors, and multi-axis sensors

- High-quality amplifiers, software, and integration solutions

- Engineering, calibration, and product lifecycle support services

- ISO 9001:2015 & ISO 17025 certified production at its Irvine, California facility

Local Support in Australia and New Zealand

Metromatics proudly represents FUTEK across Australia and New Zealand, providing customers with:

- Local sales and application knowledge

- Technical support and service

- Reliable access to cutting-edge FUTEK products

Interested in improving your robotic systems with precision torque control?

Contact us to learn how FUTEK sensors can enhance your automation performance or Robot Joint Control.