This article on Industrial Networking on Rail was kindly provided by our friends at Antaira.

Background:

In the fast-paced world of public transportation, particularly in passenger rail systems. Ensuring the safe and timely transport of large populations requires more than just well-maintained trains.

The backbone of any successful rail operation lies in its industrial networking infrastructure. Firstly, it is responsible for connecting various components. Such as pedestrian crossings, message display signs, PA systems, automated ticketing kiosks, train status displays, and security cameras. These components must work seamlessly together to collect, transmit, and process real-time data.

One of the critical challenges faced by rail operators is maintaining a network. That is not only reliable. But also resistant to the harsh environments of railway operations. Such as heavy vibrations, electromagnetic interference, and wide-ranging temperature and humidity levels are constant threats.

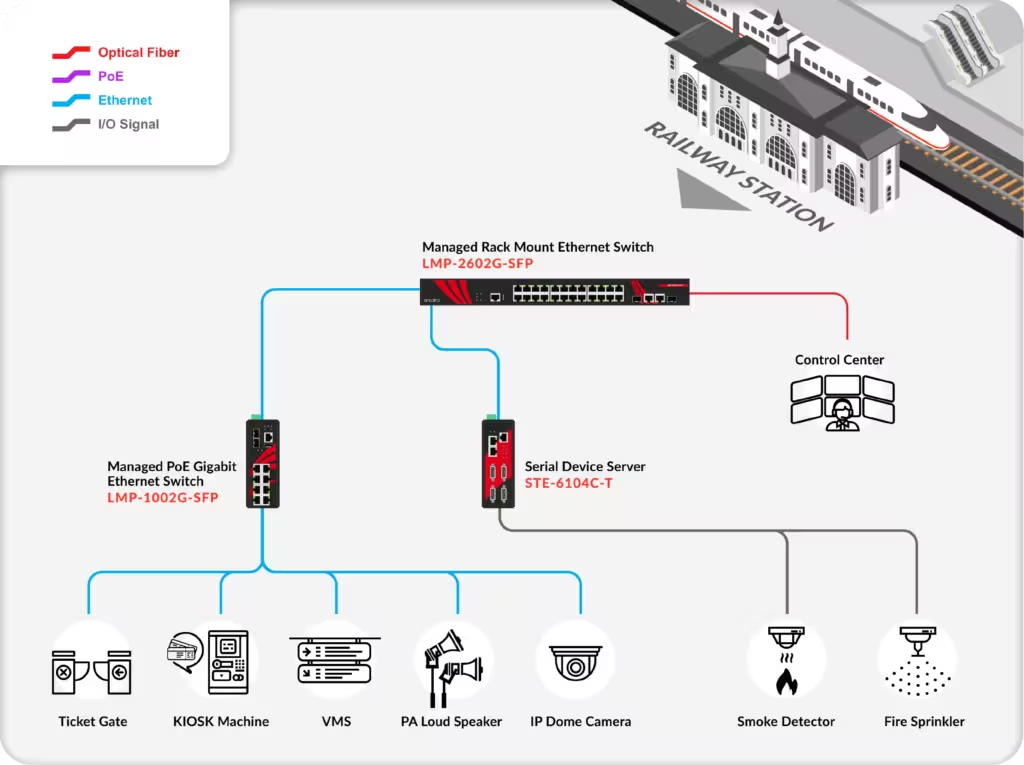

Product

LMP-2602G-SFP Managed Rack Mount Ethernet Switch

LMP-1002G-SFP Managed PoE Gigabit Ethernet Switch

STE-6104C-T Serial Device Server

A leading passenger rail operator sought to upgrade its network infrastructure. This was to ensure uninterrupted data flow between stations, intersections, and external systems. They faced several challenges:

The Challenge:

- Need for redundancy to ensure the network is operational 24/7.

- Real-time data transmission requirements between remote stations and external devices.

- Electromagnetic interference (EMI) in urban environments.

- Vibration-resistant connectivity in rail cars and trackside equipment.

- Data transmission over long distances, requiring robust wireless and fibre optic communication.

- Wide temperature and humidity range that equipment needed to withstand.

The rail operator needed a reliable solution that would address these challenges while providing easy management, reduced downtime, and secure operations.

The Solution: Industrial Networking Products for Rail

The rail operator partnered with Antaira Technologies to deploy a comprehensive solution. It consisted of Managed Ethernet Switches, M12 Ethernet Switches, and wireless communication technologies. These products were chosen for their industrial-grade durability, management capabilities, and ability to handle complex, real-time data transmission.

1. Managed Ethernet Switches for Remote Network Management

Industrial Managed Ethernet Switches played a crucial role in ensuring the network could be monitored and managed remotely. With Layer 2 network management software, the switches enabled:

- Real-time monitoring of the network.

- The use of Quality of Service (QoS) to prioritise critical data such as train control and security feeds.

- SNMP (Simple Network Management Protocol) and IGMP (Internet Group Management Protocol) for enhanced network performance.

- Email alerts to notify staff of any disruptions or issues.

- VLAN segmentation through IEEE 802.1Q to separate traffic and avoid bottlenecks.

These switches also provided Power over Ethernet (PoE) management. Therefore, allowing remote power control of edge devices like cameras and ticketing kiosks. This eliminated the need for manual resets and reduced system downtime.

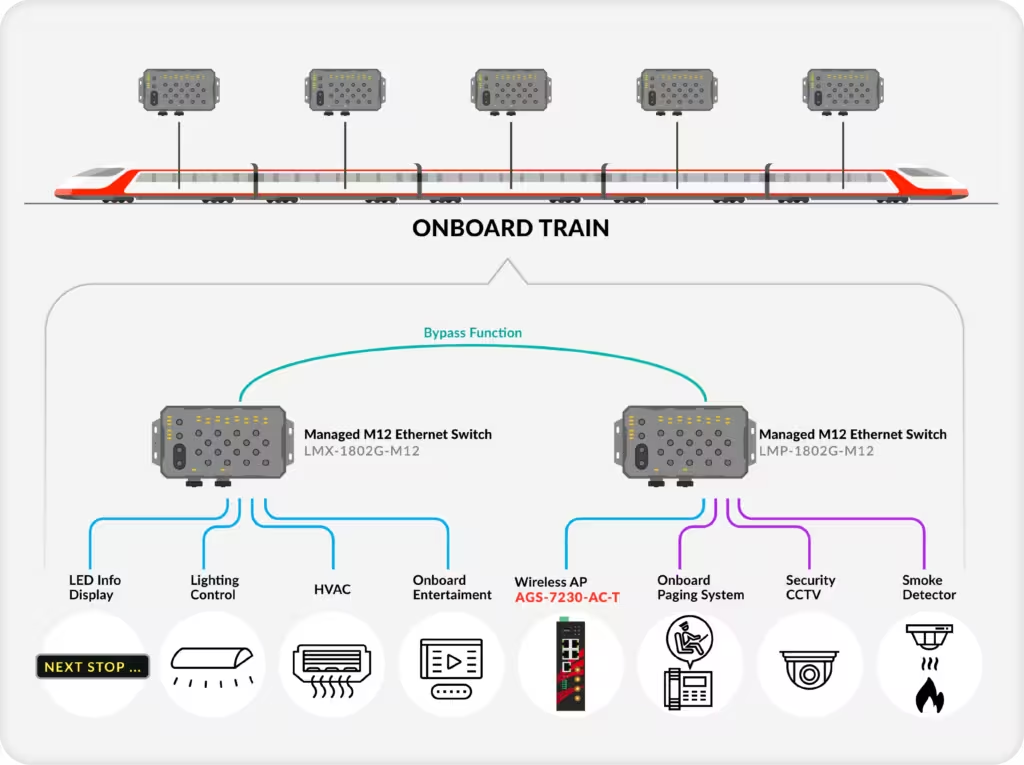

2. M12 Ethernet Switches for Vibration-Resistant Connectivity

Given the high levels of vibration in railway environments. Traditional connectors often risk disconnections, resulting in data loss and operational delays. The M12 Ethernet Switches, designed specifically for railway applications. In addition, they, feature secure, vibration-resistant M12 connectors. These connectors ensure stable and continuous Ethernet communication, even in the challenging environment of moving trains and trackside installations.

3. Wireless Solutions for Flexible Data Transmission

To handle long-distance data transmission and complex network topologies, our supplier’s wireless communication solutions were deployed. Using LTE and Wi-Fi technologies, wireless solutions offered a flexible alternative to wired connections. Therefore, enabling real-time communication between stations, remote locations, and control centres. This wireless capability allowed the operator to gather and process data from various devices without the limitations of physical cabling.

Results:

The implementation of Industrial Networking solutions provided several key benefits:

- Increased uptime through redundant network design and real-time remote monitoring.

- Reduced operational costs by automating power management and device recovery with PoE-enabled switches.

- Improved data transmission reliability in harsh environments with the use of M12 connectors.

- Enhanced flexibility in data transmission through wireless communication, boosting overall operational efficiency.

- Future-proofing the rail system’s infrastructure, allowing for easy expansion and integration of new technologies.

Conclusion:

With Antaira’s industrial networking products, the rail operator successfully upgraded its infrastructure. Therefore ensuring safe, reliable, and efficient transportation for passengers. By focusing on real-time data transmission, robust network management, and vibration-resistant connections. The system now operates with greater resilience to external challenges, offering a smoother experience for both passengers and operators.

Solutions have demonstrated that modern rail systems can benefit immensely from innovative industrial networking technologies. Such as ensuring 24/7 operation in even the most demanding environments.

Metromatics offer this product range for the Rail and Transport Infrastructure Industry in Australia. Contact us for more information or pricing.