This application note on Order Tracking Gas Turbines has kindly been supplied by our friends DeweSoft.

If you would to know more about the products used in this particular application, contact us.

Order Tracking Gas Turbines

Under the European research project ESPOSA (Efficient Systems and Propulsion for Small Aircraft (https://cordis.europa.eu/project/rcn/100644_en.html), for which COMOTI is a partner. The aim was to develop and integrate a novel design by manufacturing technologies for a range of small gas turbine engines up to approximately 1000 kW. This would provide aircraft manufacturers with better choice of modern propulsion units.

It also provided research for engine related systems. Which contribute to the overall propulsion unit efficiency, safety and pilot workload reduction, in this case the gear-box. As a producer a turbine motors, COMOTI came into this project with projecting, simulations and measurements for the transmission gear-box with a multiplication factor of 26. COMOTI has to project, simulate and test for this assembly. Among the tests it highlighted a fault detection, an Order Tracking Gas Turbines analysis was performed.

INTRODUCTION

COMOTI Turbine Engines Research and Development Institute is the only unit in Romania specialised in the development and integration of scientific research, constructive and technological design, manufacturing, experimentation, testing, technological transfer and innovation in the field of aviation turbine engines, gas turbine industrial machines and high speed blade machines.

Firstly, for testing procedures, a special stand was built (Fig. 2) on which the gears were brought to running speed. With 8 accelerometers placed axial and transversal to the axis of transmission. Secondly, the signal was transformed from time domain to the angular domain. Thirdly, the technique of Order Tracking Gas Turbines was applied. Bringing the asynchronously signals to a single sampled signal of the reference shaft. This re sampling being actually an interpolation. The FFT of the angular domain signal is defined as an order and represent a fraction of the angular velocity of the reference shaft. Finally, these orders make it possible to identify the frequencies which are related with angular speed and those which are different and which are a result of the structural vibration of the transmission gear-box.

MEASUREMENT SETUP

USED EQUIPMENT

For order tracking analysis, it used 8 analogue channels for acceleration measurement and a laser counter for measuring RPM. One channel is defined as alternatively RPM determination from FFT acceleration spectrum.

An encoder for measuring the velocity was used on a non-contact laser system with black-white marks on the shaft. For finding the eigen-frequencies related with angular speed, the Campbell diagram was plotted as a vibration response spectrum as a function of the shaft rotation speed.

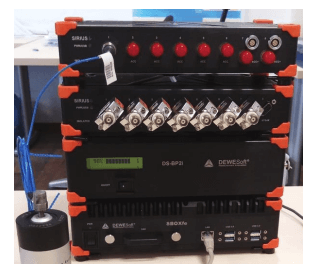

Data acquisition system

- SIRIUS 8x ACC

- Sirius 8 STG with 8 DSI-ACC converters

- SBOXfe computer battery

Sensors and transducers

- 8 Bruel&Kjaer Single axis accelerometers

- laser

Used software

Test setup

For setting up the channels, it was specified 8 channels for accelerometers and one channel for acquisition the angular speed or rotation per minute. Alternatively, the RPM was acquired from the FFT spectrum of one accelerometer.

ANALYSIS

The regimes of gear-box running on different angular speeds was found during the order tracking gas turbines analysis with Dewesoft. Using the Dewesoft OT module, the time domain data was resampled in order tracking way. It was plotted on the FFT spectrum and Campbell diagram. The angular speed was taken directly from the acceleration spectrum and from laser encoder and obtained similar results.

CONCLUSION

In conclusion, this analysis was examined to define the possible errors or faults in the ensemble of the gear box. Which may have come from unbalancing, bearing faults, gearing imprecision’s, eccentricity or assembling faults. Unbalancing was searched on the first order, eccentricity on the second order and different upper orders for bearings faults.