If you’re interested in achieving or learning about Synchronised Combustion and NVH Measurements with one Instrument on an Engine Test Bench, then you must check out this application story written by Thorsten Hartleb at Dewesoft.

Background on Synchronised Combustion on Engine Test Bench

Subjective driver experience in passenger car design is becoming increasingly important to Automotive Manufacturers. One of the key factors is the amount vibration and noise the driver is exposed to. The vehicle powertrain is identified as the key influencer.

Therefore, the basis for analysis and optimisation is understanding data from the internal combustion engine. As well as the multiple Noise, Vibration and Harshness (known as NVH) data of the driver including the environment and vehicle bus data. The only way to test synchronised combustion and NVH is on an Engine Test Bench.

The Scenario

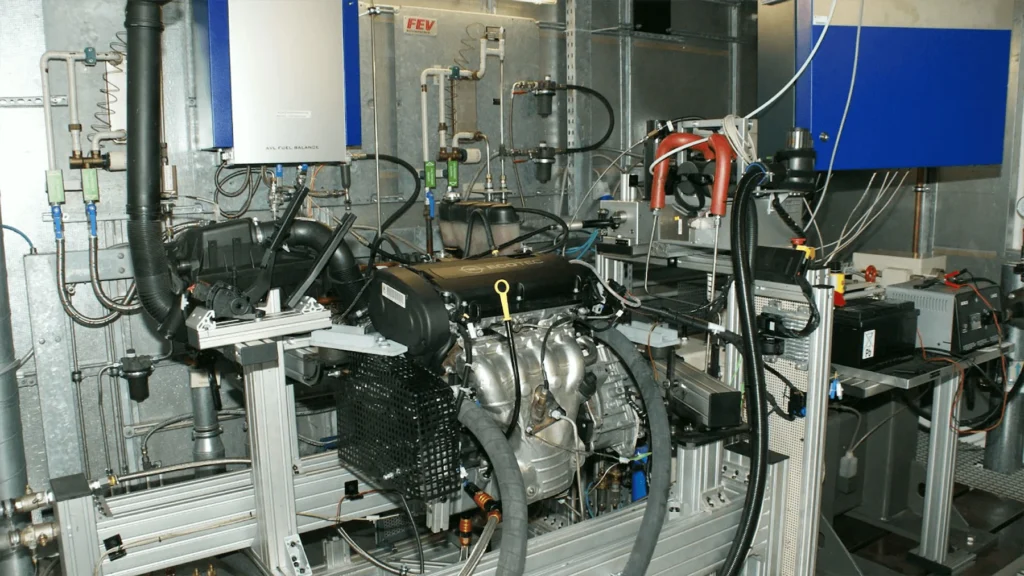

Firstly, the scenario is set at the University of Applied Sciences in Frankfurt. Laboratory Engineer Dipl.- Ing. Ingo Behr, M.H.Edu. in the Computer Science and Engineering Faculty Laboratories has been focusing on the combustion engines. He is involved in the design of the Mechanical Engineering Courses offered by Frankfurt UAS. The University is well resourced and has several engine test beds.

Problem

Ingo Behr had a problem. The lab couldn’t show the students the principal interactions between the in-cylinder pressure of a combustion engine and NVH parameters.

This was because in many measurement systems it only focuses on one application and one data set. But in more complex tasks like Mr Behr was trying to illustrate it often requires several measurement systems and unfortunately, in a lot of these systems there is no visualisation. In addition, the time required for post-processing many exported files consumed more time than the test itself.

Challenge for the University

On its test beds, the University had the challenge of simplifying measuring and gaining valuable training capacity.

Dewesoft Solution

The Dewesoft Solution enabled the university to establish synchronised measurement with visualisation as a standard approach. In addition, this method only required one measurement file for various exports. Allowing the University to do analysis and optimisation in whatever software they chose.

In this application note, Thorsten discusses the importance of achieving driving comfort and how it has traditionally been measured. In addition, he discusses working with the University and Mr Behr and how installing a simplified, visual test system was developed using Dewesoft Data Acquisition Systems and Software. As well as detailing the NVH and Combustion Analysis measurements that the students were able to make.

Hardware Configuration

Hardware configuration consisted of the

- SIRIUSi-HS-6xCHG-2xCHG+ with CAN-FD upgrade and charge amplifiers

- SIRIUS-HD-16xACC with CAN-FD upgrade and IEPE inputs

Software Configuration

Along with Software Configuration which consisted of

- DewesoftX Professional – software for signal measurement, data recording, signal processing and data visualisation and analysis.

- Dewesoft Combustion Engine Analyser – enables basic combustion analysis, recalculation from time domain to the angle domain. As well time domain for cold starts. This option also adds the combustion scope and p-V diagram visual control.

- Dewesoft Sound Level Meter Module – adds the sound level meter functionality to DewesoftX.

- Dewesoft FFT module – enables real time FFT analysis on unlimited input channels with a large selection of advanced markers and bearing faults.

In addition, a sound level meter which provided sound quality, sound intensity and torsional vibration measurements that were all completely synchronised.

The advantage of DewesoftX Software is that it supports various screens and widgets to provide a range of data visualisation possibilities. Therefore, the goal of the visualisation to have a clear overview of relevant data to verify if the measurement is valid.

In conclusion, Mr Behr was thrilled with the simplified approach and analysis process. In addition, because Dewesoft’s Systems are modular and flexible he will be able to adapt the approach for different testing combinations. Such as Hybrid Engine Analysis and NVH Analysis of Electric Cars.

Finally, Metromatics proudly sell, service and support the Dewesoft product range in Australia and New Zealand.