Dewesoft, recently published an article taking an in-depth look at the different types of current transformers used for current measurement. In this summary we’ll take a look at those technologies, their advantages, disadvantages and analyse cost and suitability.

Current Transformers

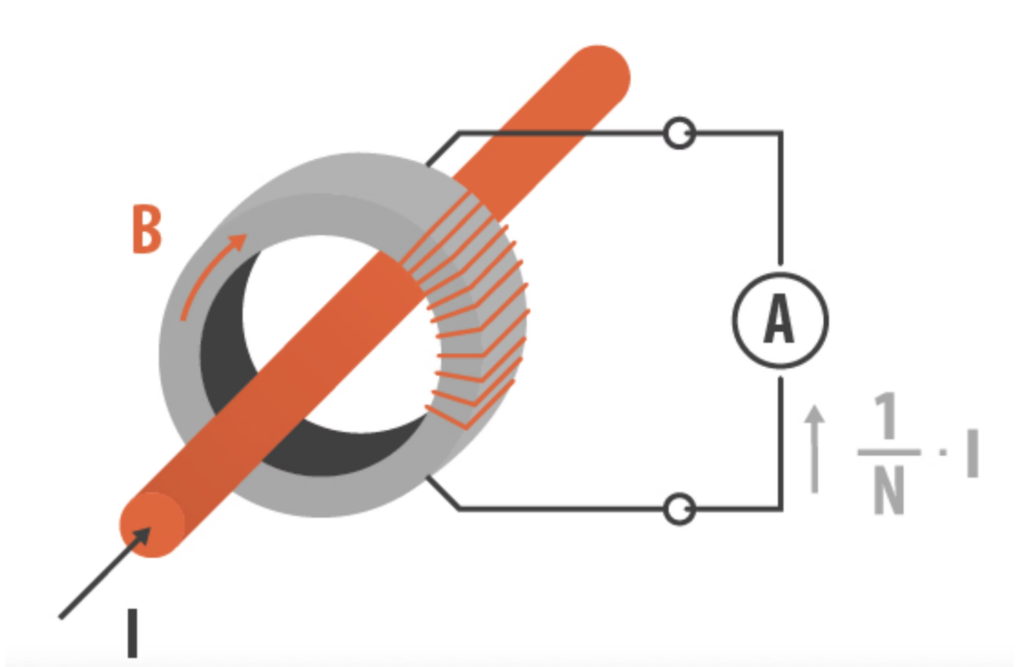

Current transformers measure alternating currents (AC). They do this by producing a reduced current that is proportional to the current in the primary circuit. This allows the Current Transformer to safely monitor and measure AC currents without directly interfacing with high voltage. This feature makes current transformers popular among electricity companies who use CTs to meter electricity and for protective relaying. Another advantage to using a current transformer is that it has excellent accuracy and high linearity. As a result, they are heavily used in power generation, transmission applications and other applications involving very high currents. With that said, it’s important to note that current transformers have a limited bandwidth, size and also weigh a substantial amount. Many people choose to use current transformers despite these drawbacks because of its accuracy and reliability. This product is perfect if you’re looking to meter and protect power systems. You can read more about this product here.

DC-CT® Platise Flux

If you’re looking to precisely and accurately measure direct currents, then the DC-CT® Platise Flux by Dewesoft is for you. This product utilizes advanced sensing methods to provide high resolution and low noise performance. It is ideal for applications that require a detailed current analysis. DC-CTs work by using a magnetic field to modulate the permeability of a core material. It is very accurate, has a low temperature drift and low power consumption. While this current sensor may be costlier than others it is great for high precision, high bandwidth applications. It also reliably and accurately measures currents and provides excellent power analysis. You can read more about this product here.

Fluxgate / Zero Flux

The Fluxgate or Zero Flux technology by Dewesoft is a sophisticated current transformer that accurately measures even the smallest currents. It’s precise in detecting very small current changes. As a result it’s ideal for applications that require high sensitivity, accuracy and low hysteresis. This technology operates by using a magnetic field that modulates the permeability of a core material. It’s great for complex designs and applications that require a sensitivity to magnetic fields and use high power consumption. You can read more about this product here.

Open-Loop Hall Effect

The Open-Loop Hall Effect sensor by Dewesoft leverages the Hall Effect principle by outputting a voltage proportional to the magnetic field generated by the current flow to measure electrical currents. Open-loop sensors are simple and cost-effective. As a result, they are suitable for a wide range of applications. Furthermore, thanks to their simple and cost effective design these sensors are moderately priced. Yet, it’s important to note that they can be susceptible to external influences and may have a lower accuracy as a result. With that said, this sensor still makes a great general purpose current.

Closed-loop Hall Effect

The Closed-loop Hall Effect sensor by Dewesoft utilizes a magnetic field to induce a voltage. The feedback then adjusts for accuracy in the current measurement. Although this current sensor has a more complex design and is higher cost it is also higher in accuracy and better at linearity. As a result, it’s great for precision applications and has a moderate price point. You can learn more about this current sensor here.

Fiber-optic currents sensors

Fiber-optic current sensors (FOCS) are distinguished by their high accuracy and immunity to electromagnetic interference. They also have the ability to measure currents without a direct electrical connection. These current sensors are especially useful in high-voltage applications and environments with strong magnetic fields. This is because they offer a safe, non-intrusive method for current measurement.

Shunt Resistor

A shunt resistor measures electric currents by placing it in parallel with a circuit. This allows a small portion of current to flow through it. The voltage then drops across the shunt resistor. The shunt resistor then measure and calculates the total current flowing through the circuit. This method is widely used for its simplicity and effectiveness in measuring high currents. This unit is simple and cost effective. One of the disadvantages to using a shunt resistor is that power dissipation can affect the circuit’s impedance. With that said, this product’s cost is on the lower end of the spectrum and it’s perfect for power supplies and battery monitoring.

Rogowski Coil

A Rogowski coil measures alternating current (AC) by using a helical coil of wire with a conductor that passes through the coil’s centre. The voltage induced in the coil is proportional to the rate of change of the current. This reading then helps measure the AC current. This product is flexible and non-intrusive. As a result, it’s suitable for irregular conductor shapes. One of the drawbacks is that it integrates signals that require additional processing. With that said, it’s great for high-frequency AC current measurements and power analysis. Finally, the Rogowski Coil by Dewesoft comes moderately priced.

Considerations When Comparing Current Transformers

What current sensor you decide to purchase will depend on the specific requirements of your application. Dewesoft’s DC-CT® is suitable for high-end AC and DC measurements. Hall effect sensors offer versatility, and specialised sensors like fibre-optics are suitable for high-voltage environments. Another factor to consider is cost. Since costs can vary depending on the Current Transformer method you choose, some buyers consider it more economical to use resistor shunts. In the end, your choice of sensor will depend on the application’s requirements, accuracy needed, and cost considerations. If you would like a more in depth detailing of these topics, please visit Dewesoft’s original article here.

Contact Us

If you would like to get in touch about these product, please contact us here.