Key Features & Benefits of the Inline 3-Axis Load Cell MTA250

True 3-Axis Sensing — simultaneously capture force components in the X, Y, and Z axes with a single sensor.

High Overload Safety — 300% safe overload of rated output ensures durability in demanding use cases.

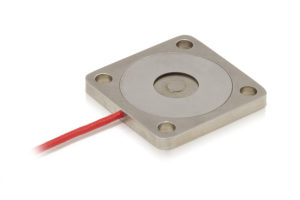

Compact & Inline Form — height 2.55 in (≈ 64.8 mm) × diameter 1.33 in (≈ 33.8 mm), with M4 × 0.7 threads.

Connectorised Design — uses 4-pin micro receptacles; simplifies cable routing and system integration.

Low Weight & Material — constructed from 2024-T4 aluminium for lightweight mechanical performance.

Repeatable & Accurate — good linearity, hysteresis, and non repeatability (see specs section).

Technical Specifications of the Inline 3-Axis Load Cell MTA250

Below is a summarised specification table based on FUTEK’s drawing and sources:

| Spec | Value |

|---|---|

| Capacities (Fx, Fy, Fz) | ± 10 lb each axis |

| Rated Output (RO) | ~2 mV/V nominal |

| Bridge Resistance | Fx, Fy: 350 Ω nominal Fz: 1,000 Ω nominal |

| Nonlinearity / Hysteresis / Non repeatability | Fx, Fy, Fz: up to ±0.15% of RO typical in many listings. |

| Safe Overload | 300% of RO across axes |

| Material | 2024-T4 Aluminium |

| Inner / Outer Dimensions | Ø 33.8 mm, Height 64.8 mm |

| Threading / Mounting | M4 × 0.7 threads |

| Overload / Safety Margins | 300% safe overload |

| Operating Temperature | –60 °F to +200 °F (–51 °C to +93 °C) |

| Connector / Wiring | 4-pin micro receptacle (CC19 wiring code) |

| Zero Balance | ±2% of RO typical (from datasheet drawing) |

Typical Applications of the Inline 3-Axis Load Cell MTA250

Embedded multi-axis sensing in robotics, haptics, or control systems

Force measurement in small test rigs or actuators

Dynamics or stability testing where Fx, Fy, Fz must be tracked simultaneously

Compact instrumentation where minimal size and axial measurement are critical

OEM systems needing a 3-axis “all-in-one” force sensor

Why Choose the Inline 3-Axis Load Cell MTA250

Compact and robust 3-axis design in an inline form factor

Strong overload tolerance for real-world use

Connectorised integration reduces wiring complexity in systems

Accurate multi-axis output in a single sensor saves space and cost

Support & calibration options — assistance in setting up axes, zeroing, calibration, and system integration

Ordering & Configuration Tips

If you would like to learn more about this product, please contact us.

Confirm which variant / sensitivity / calibration you will stock (Fx, Fy, Fz ±10 lb is typical)

Ensure correct threading (M4 × 0.7) for your mounting design

Consider your wiring / connector layout — the 4-pin micro receptacle must be compatible with your cabling scheme

Request calibration certificate or custom calibration (tension/compression) if needed

Design your system to minimise off-axis loads, align axes carefully, and provide proper mounting flats

Finally, the MTA250 is an Inline 3-Axis Load Cell. Download the FUTEK MTA250 datasheet (PDF) to view technical specifications and configuration options. Or Browse the complete FUTEK Multi-Axis Load Cell lineup.