A Power Analyzer for Vehicle Measurement Testing is needed for electric and hybrid cars to evaluate the power consumption. Dewesoft’s new SIRIUS XHS Data Acquisition System is capable of doing this and much more. It comes standard with Hybrid ADC Technology and does both high bandwidth transient recording and high dynamic alias free acquisition. It makes it possible to safely measure voltage and current accurately during real drive tests with no influence of the cable shield.

Hybrid ADC Amplifier Technology

New converter technologies in the electric vehicle market or wireless charging have very high switching frequencies (>100 kHz) due to the usage of MOSFET semiconductors. High switching frequencies come with advantages. Such as improved control characteristics as the interval between pulses is shorter. Therefore, a reduced output current ripple and it reduces the size of the total solution. By increasing the allowable cut-off frequency of the regulator’s output filter.

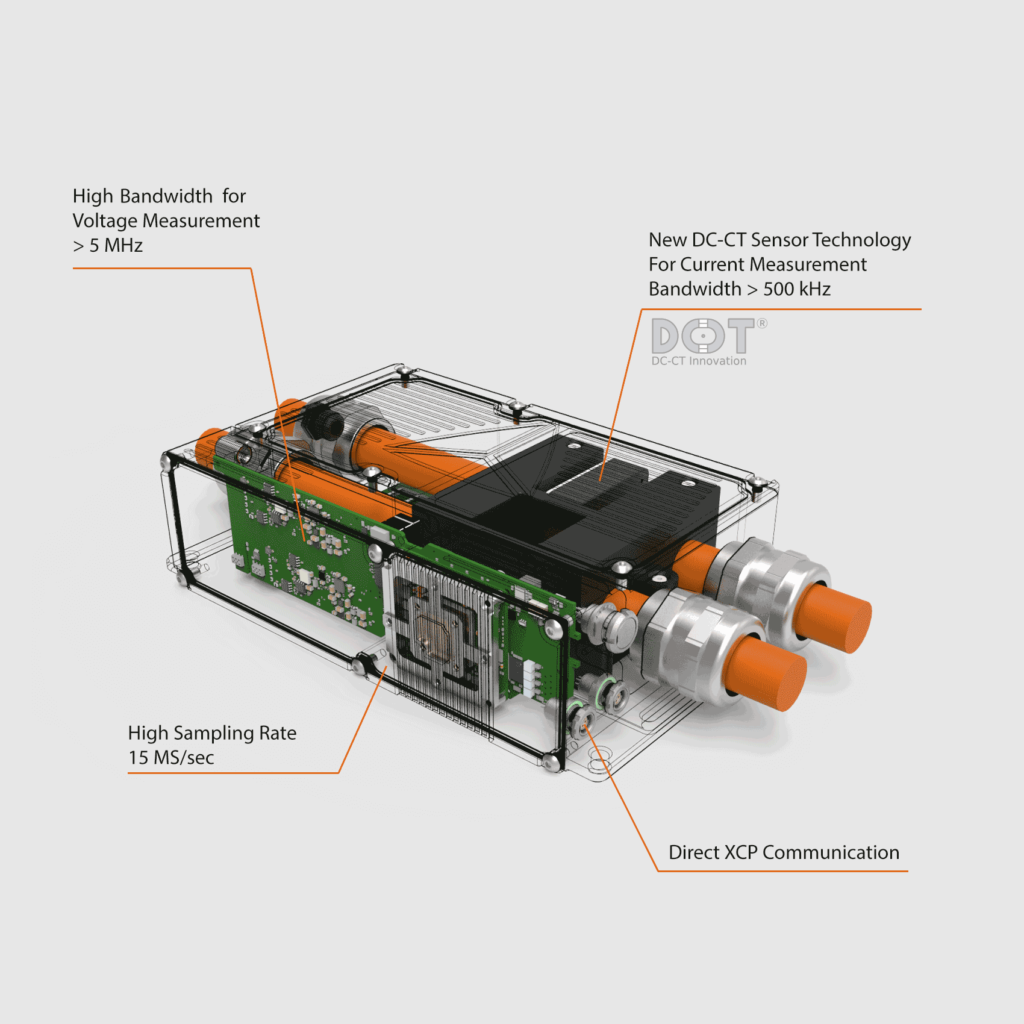

The SIRIUS XHS is capable of synchronising the channels regardless if they are set to high-bandwidth 5 MHz and 15 MS/s sampling rate, alias-free measurements at 1 MS/s, or a combination of them. The filtering design ensures that all the signals are perfectly time-aligned with a zero-phase shift. There is no Sigma-delta filtering group delay. When you mix channels from Sigma-Delta and SAR ADC devices (high bandwidth and alias-free).

An E-mobility Power Analysis Device

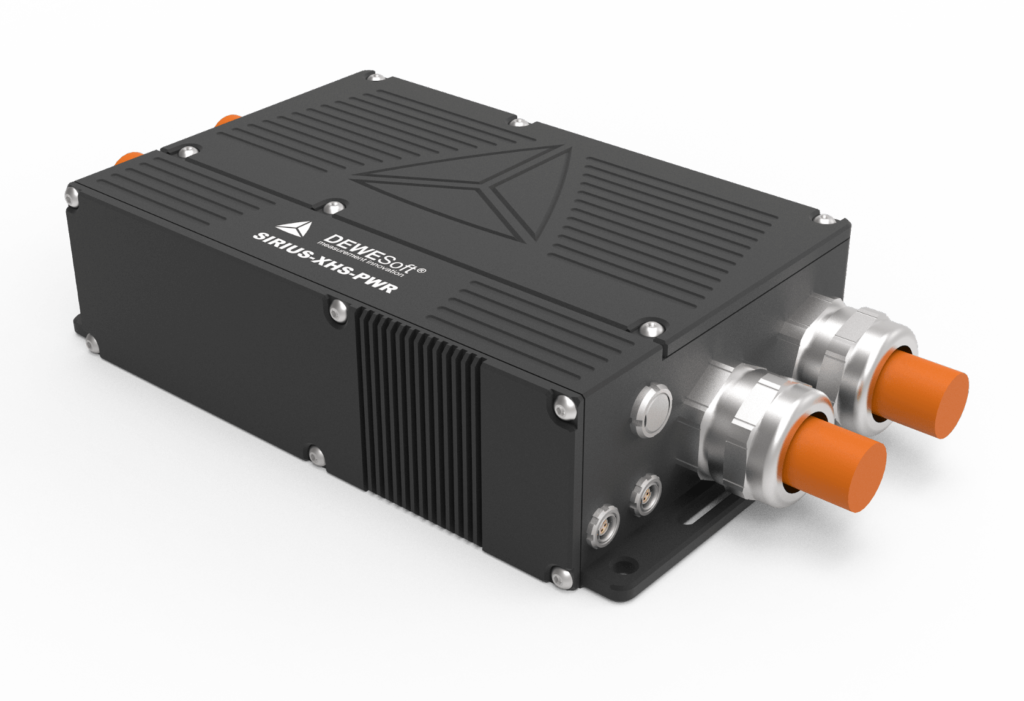

The SIRIUS XHS 1xHV,1xHA measurement device is well-suited for in-vehicle analysis. A built-in patented DC-CT current transducer allows for precise current measurements. Even in most demanding applications such as very high current peaks as well as leakage current measurements.

Learn more about the new DC-CT current transducer technology and how it works.

This measurement device is perfect for in-vehicle installation having the power lines running directly through it. This product also has an IP67 degree of protection. Making it ideal when the measurement application is destined to meet harsh environments, and the user wants the measurement to work without a hitch.

For instance, when doing an in-wheel motor drive test with four online power analysis at 5 MS/sec, the measurements are fully synchronised with each other. Data can be evaluated during the real drive test in-vehicle in real-time. Then, because all the raw data of the measurement is also stored it is possible to do a much more detailed evaluation in post-processing in the laboratory.

Power Analysis

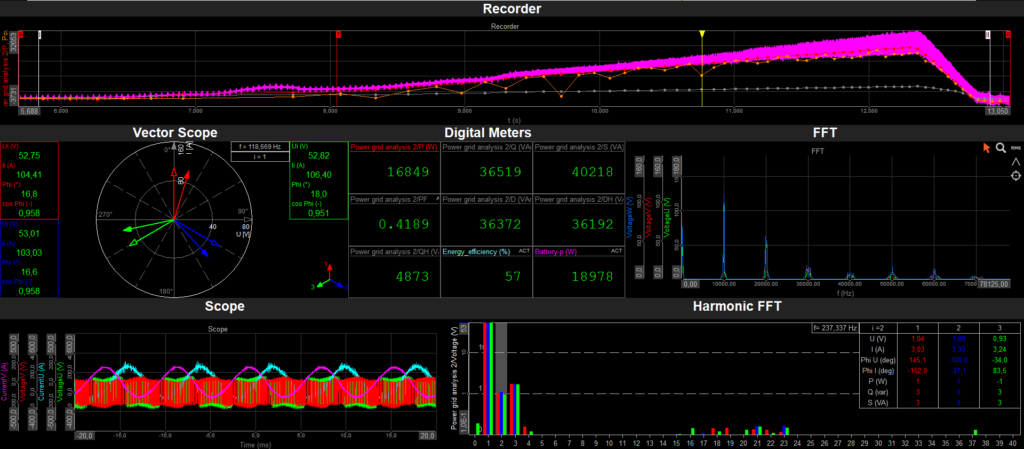

The Dewesoft X software will automatically calculate more than 100 power parameters like P, Q, S, PF, and cos φ, and many others. It also offers full raw data recording capabilities, oscilloscope, FFT, and harmonics up to the 3000th order.

The Power Analysis and Power Quality software module are also able to measure multi-phase motors (6 – 12 phases). All calculations can be done online or in post-processing.

All the calculated parameters can be visually displayed in the data acquisition software. Using one of the predefined screens that are available in the power module. As well as having the ability to set-up a user-defined custom screen that is perfectly attuned to the measurement that is being carried out. Dewesoft DAQ devices support most of the current transducers that are available on the market today.

As doing measurements at such high sampling rates puts a lot of strain on the computer’s CPU. The computer GPU is used as a multi-threaded calculation platform. The Dewesoft X power module can, therefore, calculate all the power parameters up to 15 MS/sec at full speed in real-time.

Synchronisation and Connectivity

The GLAN and USB 3.0 interfaces allow for the distribution of devices with PTPv2 synchronization. As well as the fastest possible data transfer and a quick connection to the computer respectively. In today’s world of open toolchain and intercommunication systems, each device should be compliant with standard protocols to ensure the interconnectivity. All protocols can be used at the same time.

Data is transferred to any host using the open OPC UA industry-standard protocol; in parallel the data is available over XCP protocol, allowing connection to ECU calibration software packages such as INCA. High channel-to-channel and channel-to-ground isolation prevents damage to the systems from voltage peaks and avoids ground loops.

As with any Dewesoft DAQ device, data can be synchronized to other data acquisition sources, such as vehicle bus interfaces (CAN, CAN FD, XCP, CCP, FlexRay), GPS/IMU, video, and digital counters among others. Devices can be synchronized between each other using a PTPv2 mechanism, IRIG, or PPS signal. This also provides absolute time synchronization using in-house time servers or GPS.

Award-winning Data Acquisition Software Included

All Dewesoft data acquisition systems are bundled with the award-winning Dewesoft X Professional DAQ software – the most advanced and easy-to-use data acquisition and analysis software with lifetime upgrades.

Dewesoft X’s flexibility and capability. Unleash the DAQ system to its full potential and provide advantages over other DAQ systems. Functionalities like plug-and-play, hardware auto-detection, smart TEDS sensors, advanced storing, and data analysis features that take the measurement and analysis experience to a whole new level.

The SIRIUS XHS has been developed to give engineers the freedom of choice when measuring power with the highest precision. This usually requires an array of measurement equipment. In this case, less is more! A high precision compact measurement device using the state-of-the-art Dewesoft X software concurrently replaces the need for extensive amounts of equipment such as an oscilloscope, power analyser, power quality device, data logger, etc. All whilst adhering to the highest safety ratings to ensure the safety of the users.

Contact us to find out more.