This case study on an Electric Dirt Bike Vs Gas Dirt Bike Test & Comparison comes from our innovative friends at Dewesoft. The original article was written by Valentino Pagliara, a support Engineer at Dewesoft S.r.L, Italy. To read the original, click here.

Summary of Electric Dirt Bike vs Gas Dirt Bike

Dewesoft is recognised worldwide for their easy-to-use Data Acquisition Measurement Systems. As well as their top-notch support of companies who conduct R & D using Dewesoft’s measurement systems. However, I think their biggest enjoyment is getting their hands dirty and actually applying the Dewesoft instruments into real world testing situations. They never let an opportunity go by.

So, we’ve all heard people’s comments about electric vehicles. Such as “Electric vehicles never being able to give the sensations that driving a motor vehicle does” and ”how much more satisfying it is to hear silence from an electric motor”. Therefore, you’re either pro Electric Vehicle or Traditional Car. Or in an Australian context and to do with V8 motor racing – you’re either Ford or Holden.

The opportunity evolved from a new application – Electric Dirt Bikes. Dewesoft Italy decided to compare the capabilities of two motocross bikes – one with an internal combustion engine and one with an electric one. They had help from a Motocross friend of theirs. Their aim was to answer: which one is better?

Picture 1: Motocross is a form of off road motorcycle racing.

The Motocross Driving Expert – Valerio Lata

Valerio Lata, a friend of Dewesoft was nominated as the driver of this test. He is the official driver of KTM, the Austrian motorcycle, bicycle and sports car manufacturer and a Motocross EMX 125cc European champion.

Picture 2: In 2021, Valerio Lata won the European Championship in the EMX 125cc class

Whilst only 17, Italian born Valerio has been riding motorbikes since he was 5. He joined motocross at 7 and last year he entered the European Title in the 250cc class. Valerio was the perfect rider to conduct this test.

Picture 3: Left is the electric motorbike and the right is the motorbike with an internal combustion engine involved in the measurement campaign.

All that was left was the Italian Dewesoft team had to prepare all the equipment and ensure that the measurements they obtained were, as always, as accurate as possible.

The Challenge

Firstly, the largest challenge they faced was to equip the bikes with the Dewesoft Data Acquisition Systems. This would involve getting in amongst it. The Italian team was up for the challenge.

The Measurement Instrumentation Setup

Firstly, they wanted to equip both dirt bikes with the Dewesoft DAQ systems. As this would allow them to measure acceleration, speed, roll, altitude data, pitch and yaw. This information would allow the team to evaluate and compare the performance of the bikes and their rides.

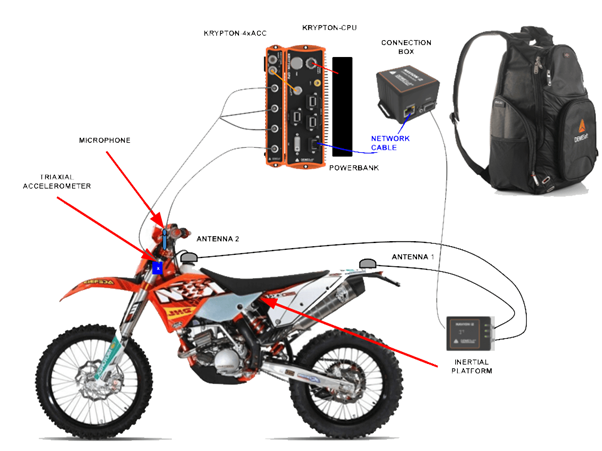

Picture 4: Measurement set up diagram

The measurement setup – see picture 4 – chosen for the project consisted of:

- The brand-new Dewesoft inertial platform Navion2i – see figure 4

- A triaxial accelerometer ICP 10 mV / g, 500 g, 2 at 7 kHz, model PCB 356B21

- One 1/2 “pre-polarized free-field condenser microphone, 50mV / Pa (+/- 1.5dB), 3.75Hz – 20kHz (+/- 2dB) with 1/2 ” ICP® preamp “(426E01) and TEDS (PCB model 378B02)

- A Krypton CPU to acquire the data. Perfect thanks to its small size.

- A Krypton-4xACC acquisition system for dynamic measurements

- A power bank to free up the power supply of the motorcycle

- The DewesoftX data acquisition and processing software,

- An action camera – placed on the driver’s chest – to film the entire driving experience and easily synchronize it with the data acquired thanks to the many functions of the DewesoftX software

- A KTM 125 internal combustion engine motorcycle

- An electric KTM motorcycle

Picture 5. The new Dewesoft inertial platform, Navion2i.

Installation of the Components

After analyzing and studying the motorcycle frames they identified where to place their systems. With the support of the team of the ASD Motor Racing Vitinia – an amateur sports association and motocross school – and they began the installation.

While dealing with minimal spaces, the compactness of Dewesoft devices made installation quick and easy. First, they installed the two GPS antennas. In this case, the discriminating factor that guided them was to maintain a minimum distance of 1 metre between them. The distance of 1 metre is short. Especially, if you compare it to some systems of their competitors that require at least 2.5 metres between the antennas.

To achieve the right distance, they created a simple custom “L” bracket. This, anchored to the tank cap of the motorcycle with the combustion engine, served as the basis for the front antenna – see figure 6. On the electric motorcycle, the GPS antenna was anchored with 3M cloth tape to the frame just below the onboard computer.

Figure 6. GPS antenna mounted on the custom bracket.

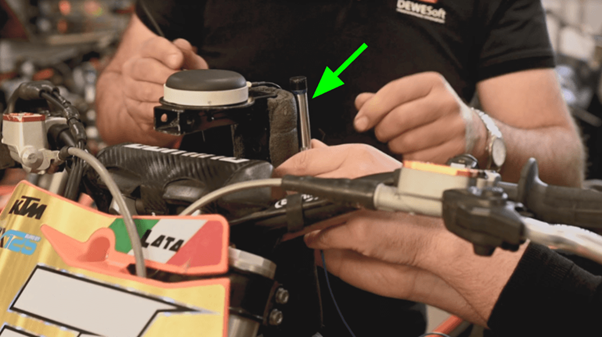

The “L” bracket was also used to install the microphone, which was anchored on the long part of the bracket using ordinary plastic ties – see figure 7.

Figure 7. Anchoring the microphone to the custom bracket.

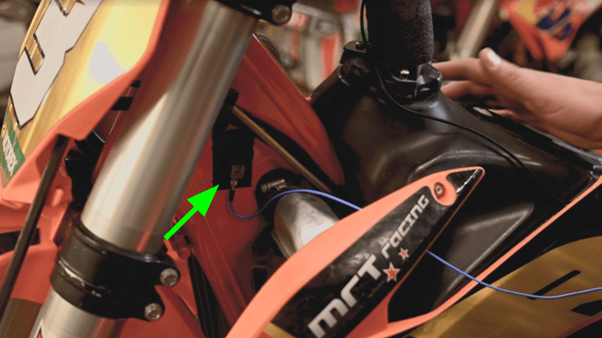

The IEPE accelerometer, on the other hand, was positioned directly on the bike frame, just below the handlebars – see figure 8.

Figure 8. Fixing the IEPE accelerometer to the frame.

They then moved on to fixing the other antenna. In this case, they took advantage of the stiffness of the rear wheel mudguards of the motorcycles. These provided them with an excellent anchoring base and, again with the help of the duct tape, they secured the GPS antenna on the rear – see figure 9.

Figure 9. GPS antenna is mounted on the rear fender of the motorcycle.

Installing the Navion2i

Having positioned the antennas, they moved on to fixing the Navion2i on the body of the bike. To ensure accurate measurements, this must be installed in a horizontal position in relation to the ground and, if possible, near the centre of gravity of the vehicle.

To respect the requirements described above, they decided to place the Navion2i in a space close to the air filter. Again, installation took only a few minutes.

Once the plastic casing on the side of the bikes was removed, they had easy access to the compartment with the air filter. Once there, the small size of the Dewesoft device did the rest. Secured with plastic ties and duct tape, the Navion2i was ready – see figure 10.

Figure 10. Positioning of the Navion2i in the air filter compartment.

The backpack to house the Datalogger, DAQ Unit and PowerBank

All that remained was to position the Krypton CPU datalogger, the Krypton-4xACC data acquisition unit, and the power bank. In this case, the compact dimensions and the lightness of the devices allowed them to solve the problem with a perfect solution that ensured accuracy in measurements and driving comfort for the rider.

The three devices were placed inside a small backpack – see figure 11. The wiring was carefully sized to allow any type of rider movement during the driving phases.

Figure 11. The backpack with the Krypton CPU data logger, the Krypton-4xACC acquisition unit, and the power bank inside.

Therefore, Valerio didn’t have to do anything – just put on his backpack before hitting the track – see figure 12.

Figure 12. Valerio Lata on the electric bike just before starting a test ride.

Measurements on the Track

The track was – “Il Tridente di Nettuno” cross-track, just outside Rome.

Valerio first brought the electric motorcycle to the track and then the one with an internal combustion engine. He immediately launched into a series of fast laps – didn’t even need a lap of the track to familiarise himself with the feel of Dewesoft’s measurement setup on the bike.

Watch the video:

“The instrumentation didn’t bother me when driving, I almost forgot I had a backpack on my shoulders” , Valerio told us back in the garage.

The instrumentation and measurement setup responded perfectly. Thanks to the DewesoftX software, the acquired data was already available between one session and another. This allowed them to verify the validity of the measurements carried out, and to make initial analysis and evaluations.

Having the acquired data immediately available is of huge added value. This is because it allows you to adjust and optimise the measurement campaigns. Plus direct them towards details or problems that were ignored or unknown before starting the actual tests.

The Results

The test rides spurred the Italian Dewesoft’s Teams emotions – excitement, disbelief, and admiration – and “gave us a lot of hard data to analyse and reflect on”.

After the rides, Valerio said: “The electric bike seems to perform better in mixed sections, but the bike with an internal combustion engine allows me to jump better. I’m really curious to see the comparison of the data acquired to see if my feelings are confirmed by objective data!”

Having tested the vehicles on the same circuit and with the same driver, Dewesoft were confident that the data collected was really indicative of a comparison between the two motoring philosophies.

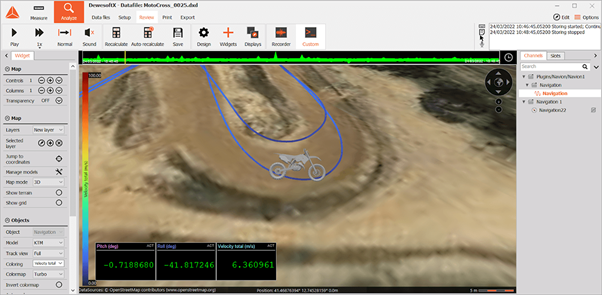

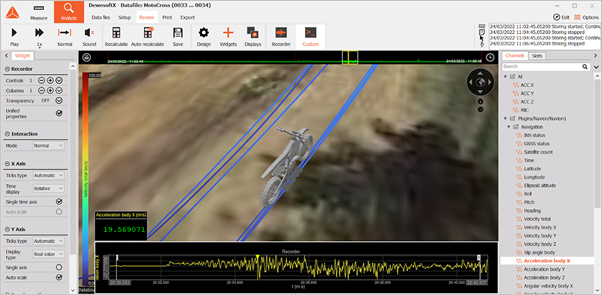

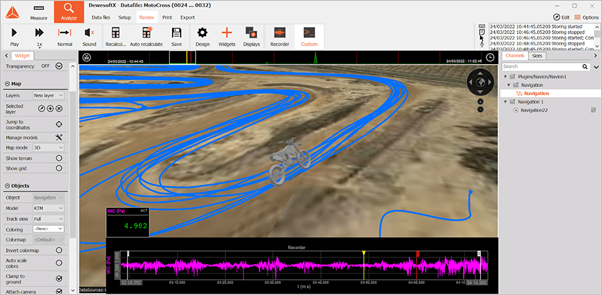

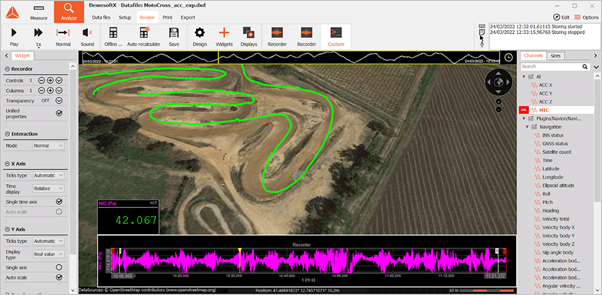

First of all, the use of the Navion2i allowed them to characterise the different behaviour of the two bikes from a dynamic point of view – see figure 13.

Figure 13. Analysis of data from Navion2i.

Entering the acceleration field – see figures 14 and 15 – the behaviour of the two bikes amazed the analysis team. The data on revolutions per minute showed how the electric motorcycle offers prompt and immediate thrust right from the very low revs. Whilst the petrol engine version offers stronger performance at higher revs.

Figure 14. The electric KTM bike – maximum acceleration out of corners.

Figure 15. The KTM bike with internal combustion engine – maximum acceleration in corner exit.

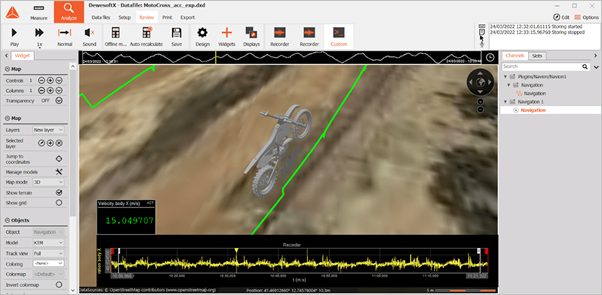

Analyzing the speeds of the two bikes on a stretch of track the performance of the bikes is very similar, though the petrol KTM has a much longer reach – see figure 16.

Figure 16. Speed - Internal combustion engine KTM vs Electric, (Navion2i).

Riding Style Conclusions

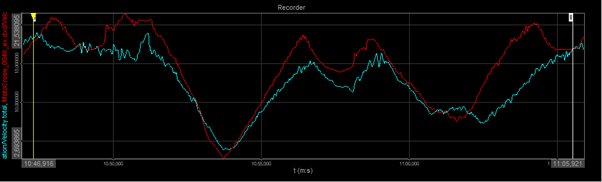

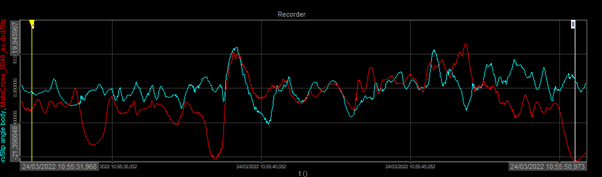

Another interesting fact that observed is: the driver’s different driving styles riding the electric KTM compared to the traditional KTM. The first part of the graph shows how Valerio brakes down more both at the entrance and at the exit of curves with the petrol bike. Yet, he is more composed with the electric counterpart – figure 17.

Surely such observations may have been predictable, but with the Navion2i it provided the opportunity to quantify the ride differences. This is a tool widely used in automotive development to objectify vehicle longitudinal, lateral, and dynamic performance in general.

Figure 17. Slip angle – Internal combustion engine KTM (in red) vs Electric (in turquoise), (Navion2i).

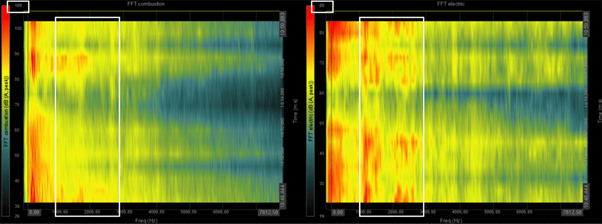

Noise Analysis Conclusions

The noise analysis – see figures 18 and 19 – on the other hand, confirmed what the team expected… a “rumble against a hiss”. While Valerio was riding the electric motorcycle, the noise of the drone trying to keep up with him was much louder than the noise of the bike itself.

Figure 18. The electric KTM bike – measurements of the microphone in full acceleration.

Figure 19. The KTM bike with internal combustion engine – measurements of the microphone in full acceleration.

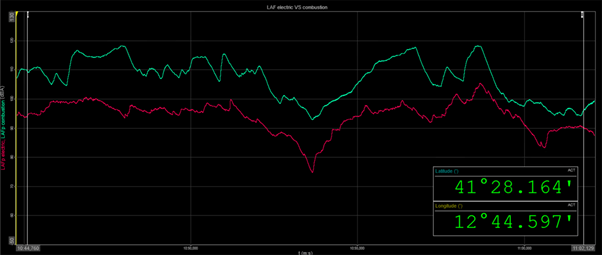

The data also confirms that the thermal combustion engine always has a significantly greater contribution when measuring the simple sound pressure level LAF.

In figure 20 the LAFs for the electric and combustion engines were compared in the same portion of the track – thanks to the GPS positioning information of Navion.

Figure 20. LAF sound pressure levels – Internal combustion engine KTM vs Electric.

On the other hand, the analysis of the frequency content of the two recordings is more interesting – see figure 21.

In the case of the electric motor, they see that even in the 1000-3000Hz range there are components not negligible compared to the total. Whilst no dominant harmonics are detected in this range for the combustion engine.

Such analysis allows objectification of the acoustic signature of the electric motor. Which is often the subject of more in-depth studies aiming to modify the acoustic behaviour, labelled by many as not very satisfying.

Figure 21. Characteristic frequencies – Internal combustion engine KTM vs Electric.

The Rider’s Conclusions

Certainly, in such a comparison, in addition to the data, it is also important to take into account the sensations experienced by the rider.

At the end of the day, Valerio told the team: “It was the first time I was riding an electric motorcycle on the track and I must say that it amazed me. I didn’t expect the acceleration and aggression out of corners to be so significant”.

Which one is then better? “I don’t know which of the two I prefer to drive, but I can say that I had a lot of fun with both”, Valerio said. “One thing is certain, the transition from an internal combustion engine to an electric one involves a change in driving style. This aspect should not be underestimated, especially for those approaching the world of two wheels for the first time”.

In the end, the EMX 125cc European Champion concluded: “I am unable to choose a motorcycle from this comparison”.

The Conclusion

The measurement campaign carried out on the track gave some confirmations, but also showed aspects that were not so obvious to expect.

Dewesoft data acquisition systems have proven to be perfect for high-difficulty applications like this one. They withstood significant stresses like jumps, bumps, and hard impacts with the ground – and the driving of a champion, without any suffering. Their small size and low weight allowed the Dewesoft team to create a setup. It guaranteed great measurement performance and the right driving comfort for the driver.

As to the question from which Dewesoft initially posed – whether an electric dirt bike vs gas dirt bike and which one is better – however, sorry to disappoint you, because …

There is no answer! As the ancient Romans used to say, “De gustibus non disputandum est” – there is no accounting for taste!

Figure 22. Valerio Lata with some of the guys from our team – the Managing Director of Dewesoft Italy, Gabriele Ribichini, and Global Assistant VP Sales, Bojan Čontala.

For more information on the Electric Dirt Bike Vs Gas Dirt Bike, contact us.