Measuring Rotary Shaft Thrust with Load Cell and Rotary Load Cell

Rotary shafts are at the heart of many industrial systems, from motors and turbines to pumps and robotic systems. Accurately measuring the thrust they generate is critical and achieved by using load cells and rotary load cells. Such as donut/through-hole load cells, which offer precise thrust measurement for a variety of applications.

Why Measure Rotary Shaft Thrust?

Understanding and monitoring rotary shaft thrust is essential for maintaining the health and efficiency of industrial machinery. Excessive or insufficient thrust can lead to operational inefficiencies, equipment damage, or even system failure. Measuring thrust with load cells and rotary load cells provides actionable insights to:

- Optimise Performance: Fine-tune equipment to operate at peak efficiency.

- Prevent Failures: Detect issues like misalignment or excessive force before they cause breakdowns.

- Ensure Safety: Protect workers and machinery by monitoring dangerous operating conditions.

Application Summary: Measuring Rotary Shaft Thrust with a Load Cell

To ensure turbines, drills, linear actuators, and lead screw systems perform efficiently and reliably, testing is essential. Shaft thrust measurement helps optimise system performance, which, in turn, maximises the design and life of the bearings.

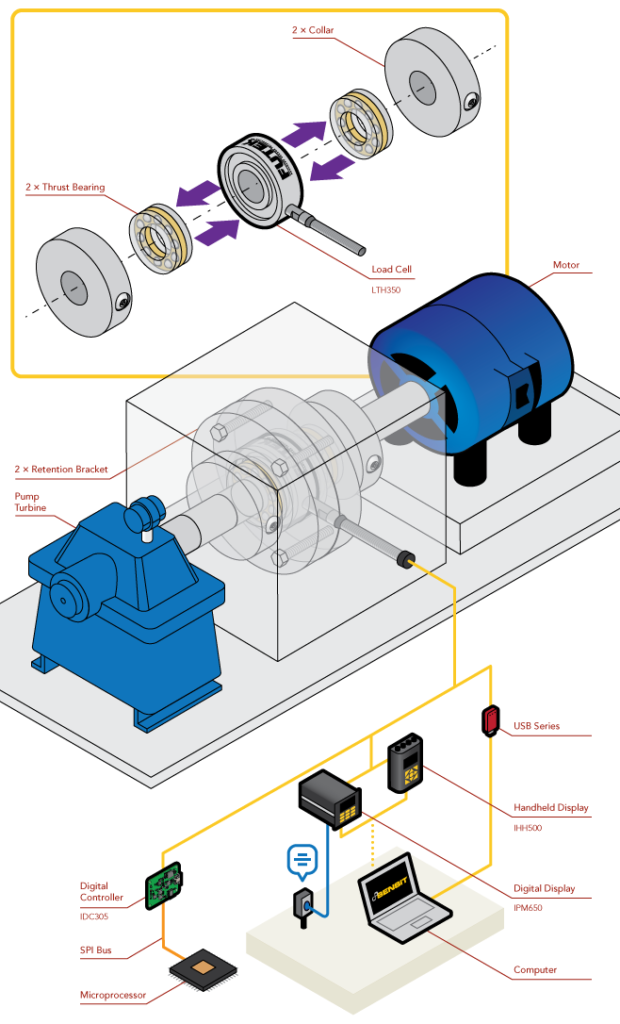

One ideal solution is the use of a donut load cell, such as the FUTEK LTH350 Donut/Through Hole Load Cell, which can operate in tension and compression. This type of sensor is perfectly suited to measure the thrust applied to a shaft in real-time.

Products in Use

- LTH350 Donut/Through Hole Load Cell

- Paired instrumentation options include:

How It Works

The process of measuring rotary shaft thrust with the LTH350 Donut Load Cell involves these steps:

- Sensor Placement:

The LTH350 Donut/Through Hole Load Cell is freely slid onto the shaft. - Bearing and Collar Setup:

A pair of thrust bearings and collars secure the donut load cell in place on the shaft. - Retention Bracket Attachment:

A retention bracket is attached to the outer circumference of the sensor, anchoring the sensor to a solid fixture. - Load Transmission:

As thrust forces are applied to the shaft, the bearings and collars transmit the load through the sensor for measurement, delivering the load to the retention bracket. - Real-Time Display:

The IHH500 Digital Hand-Held Display and the IPM650 Panel Mount Display capture and display the measured load in real-time. - Data Recording:

Force data can also be captured simultaneously using the USB220 High-Resolution USB Solution and FUTEK’s SENSIT Software on a PC, providing detailed analysis and reporting.

Applications of Rotary Shaft Thrust Measurement

Rotary load cells and through-hole load cells are versatile tools that find use in a variety of industries, including:

- Turbines and Generators:

Monitor thrust to optimise bearing design and prevent system failures in power generation systems. - Drills and Actuators:

Measure forces in lead screw actuators to ensure alignment and peak performance. - Robotics and Automation:

Enhance precision in robotic arms and rotary actuators by accurately measuring applied forces. - Material Testing Machines:

Collect real-time data for load testing and performance analysis of rotating components.

Conclusion

Accurately measuring rotary shaft thrust with load cells and rotary load cells is vital for maximising the performance, safety, and reliability of rotary systems. Solutions like the LTH350 Donut Load Cell and compatible instrumentation provide engineers with the tools to capture real-time data and optimise system efficiency.

Metromatics offers a range of load cells, rotary load cells, and supporting instrumentation to meet your specific application needs. Contact us today to learn more about our solutions or to request a quote.