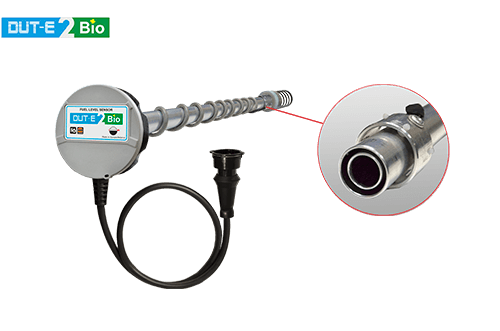

The DUT-E 2Bio is a differential fuel level sensor. Designed to measure fuel volume and automatically detect changes in fuel type or quality. Ideal for vehicles and machinery that may operate using blended fuels. Such as biodiesel or fuels with varying chemical compositions across regions.

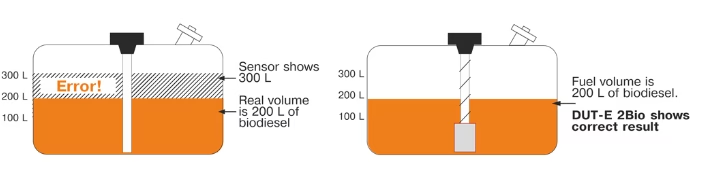

It features a third capacitive electrode. This means the DUT-E 2Bio goes beyond traditional fuel level sensing. Providing data that not only reflects how much fuel is in the tank but also gives insight into what type of fuel is being used. This feature allows users to identify potential misuse or fuel substitution, protect engine performance, and ensure fuel quality compliance.

DUT-E 2Bio integrates easily into GPS tracking and telematics systems. In addition, it is powered by the IoT Burger® and S6® technologies. Therefore, enabling onboard data processing and sensor-to-sensor networking over a single cable.

Key Features

🔍 Fuel Type Detection

Automatically detects changes in fuel composition using a third measuring electrode – perfect for biodiesel monitoring or ensuring fuel consistency across regions.🧠 IoT Burger® Onboard Processing

Filters and processes raw fuel data inside the sensor, sending only clean and stable information to your telematics platform.🔗 S6 Technology Support

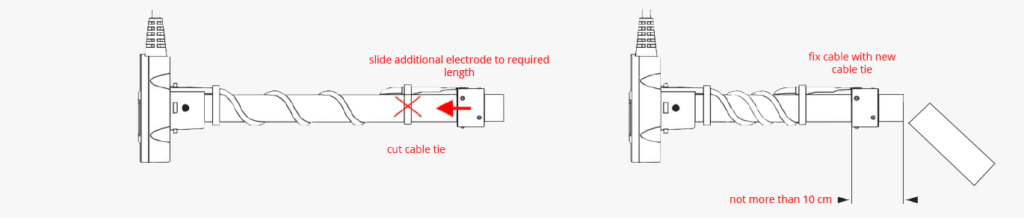

Easily integrates with other S6-compatible sensors using a single cable for both power and data. Therefore, ideal for systems with multiple tanks or complex fuel systems.📏 Adjustable Probe Length

Probes are available in standard sizes (700 mm and 1000 mm). In addition, they can be cut or extended (up to 6000 mm) to suit your tank depth.🔧 Simple Installation

Designed for easy mounting with a standard 5-bolt flange and a wide compatibility range for different tank types.🔌 Flexible Output Options

Available with multiple output signal types including:Digital: CAN J1939/S6, RS-232, RS-485 Modbus

Analog: Voltage (1–9 V), Frequency (500–1500 Hz), or Current (4–20 mA). Analog Outputs are optional and available on placement of order.

🌡️ Rugged Design for Harsh Environments

Built to perform in temperatures from -40°C to +85°C, with excellent protection against overvoltage (up to 100 V) and EMI.

For more information, contact us.

🔧 Customising the DUT-E 2Bio Probe Length

The DUT-E 2Bio sensor probe can be easily adjusted to match the depth of your fuel tank. You can cut the probe to shorten it, or extend it using optional extension sections — up to a total length of 6000 mm. This flexibility makes it suitable for a wide range of tank sizes and applications.

Specifications on the DUT-E 2Bio

| Operating Principle | Capacitive |

| Measurement inaccuracy | 1% |

| Supply Voltage | 10 to 45 V – however, protection to 100 |

| Current Consumption (DC 24/12V) | <25/50mA |

| Probe Length | 700mm or 1000mm (can be manufactured up to 6,000mm on request) |

| Output Signal | CAN j1939/S6, RS-232/485 Modbus, Voltage, Frequency or Current |

| Temperature range | -40°+85°C |

| Installation | Standard 5 Bolt Flange |

Applications

🚛 Fleet & Commercial Vehicles

Monitoring blended fuel use in trucks operating across different regions

Ensuring consistent fuel type in logistics and freight vehicles

Detecting fuel substitution in rental or leased vehicles

🏗️ Construction & Heavy Equipment

Monitoring fuel quality and levels in generators, dozers, and excavators

Tracking consumption and refuelling on remote job sites with mixed fuel sources

🚜 Agriculture

Managing biodiesel use in tractors and harvesters

Preventing damage caused by improper fuel blends in farm equipment

🛢️ Stationary Fuel Tanks & Storage

Monitoring fuel level and type in industrial backup generators

Checking fuel quality in bulk diesel or biodiesel storage tanks

🏭 Industrial Applications

Ensuring process fuel consistency for burners, boilers, and heavy machinery

Fuel tracking for compliance in off-grid or remote power systems

Installation & Integration

The DUT-E 2Bio installs via a standard 5-bolt flange and is supplied with optional mounting kits to suit your tank. The probe can be cut to length or extended with additional sections, making it suitable for tanks of almost any depth.

Configuration is simple via Bluetooth (optional S6 BT Adapter) or directly through a telematics interface using S6 tools. Output signals are compatible with a wide range of tracking and monitoring systems including CANbus, RS-485 Modbus, and analog interfaces.

Compatible Accessories

Mounting Kit (MK DUT-E) – for secure sensor installation

S6 BT Adapter – wireless configuration via smartphone or tablet

S6 SK Service Kit – for diagnostics and firmware updates

Probe Extension Sections – to increase probe length up to 6000 mm

Fuel Supply Automation Units (DUT-E SAU) – for more advanced systems