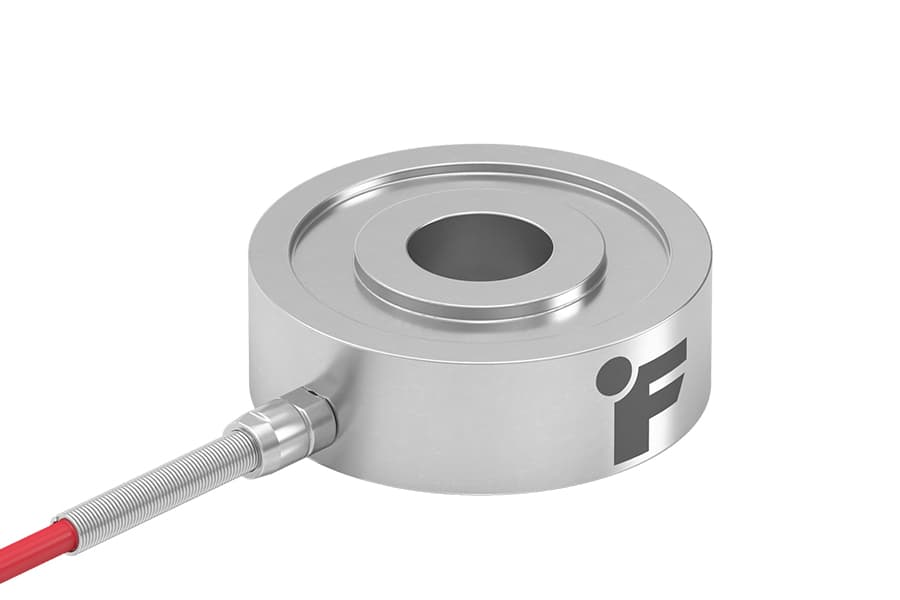

Key Features & Benefits of the Donut Through-Hole Load Cell LTH 400

True Through-Hole (“Donut”) Design – enables your mechanical component (bolt, rod, shaft) to run through the sensor while the load is measured around it.

Low Profile & Compact Diameter – Typical height of 0.630 in (≈16.0 mm) and outer diameter ~1.980 in (≈50.3 mm), making it suitable for installations with limited vertical space.

Multiple Inner Diameter Options – Various I.D. sizes (e.g. 3/8″, ½”, 5/8″) to match your bolt or shaft dimensions.

High Accuracy & Robust Output

Nonlinearity ±0.25% of RO

Hysteresis ±0.50% of RO

Nonrepeatability ±0.05% of RO

Strong Electrical Performance

Rated Output: ~2 mV/V nominal

Bridge Resistance: 700 Ω nominal

Insulation Resistance ≥ 500 MΩ @ 50 VDC

Durable & Rugged Construction – Made of 17-4 PH stainless steel, with conformally coated internals for shock, vibration, and environmental protection.

Sealed & Connectorized – IP67 rating for short submersion or harsh environments; uses a 4-position micro circular connector (CC19) for quick connect/disconnect.

Low Deflection & High Natural Frequency – Deflection ~0.002 in (0.05 mm) under rated load helps maintain stiffness and dynamic response.

Temperature Performance

Operating: –60 to +200 °F (≈ –50 to +93 °C)

Compensated: 60 to 160 °F (≈ 15 to 72 °C)

Temperature shifts small for zero/span per °F/°C

Technical Specifications of the Donut Through-Hole Load Cell LTH 400

| Specification | Detail |

|---|---|

| Capacities | Up to 10,000 lb (~44,480 N) (various inner diameters) |

| Rated Output (RO) | ~2 mV/V nominal |

| Nonlinearity | ±0.25% of RO |

| Hysteresis | ±0.50% of RO |

| Nonrepeatability | ±0.05% of RO |

| Safe Overload | 150% of RO |

| Bridge Resistance | 700 Ω nominal |

| Deflection | ~0.002 in (0.05 mm) |

| Material | 17-4 PH stainless steel |

| IP Rating | IP67 (short term submersion / environmental sealing) |

| Connector | 4-position micro circular (CC19) |

| Operating Temp | –60 to +200 °F (–50 to +93 °C) |

| Compensated Temp | 60 to 160 °F (15 to 72 °C) |

Typical Applications of the Donut Through-Hole Load Cell LTH 400

The Donut Through-Hole Load Cell (LTH400) is ideal for:

Measuring bolt preload / clamping forces in assemblies or bolted joints

Inline compression sensing in presses, clamps, or fixtures

Structural force measurement where a rod or shaft must pass through the sensor

Industrial automation or machinery with tight space constraints

Load monitoring in test rigs, manufacturing lines, and quality control environments

Why Choose the Donut Through-Hole Load Cell LTH 400

True through-hole design simplifies mechanical integration without detours around bolts or shafts

High accuracy & rugged build ensures dependable readings even under vibration and load disturbances

Connectorized & sealed – quick disconnects and IP67 rating support maintenance and harsh environments

Low deflection and high natural frequency help with dynamic performance and stiffness in your system

Support & calibration – Metromatics can help calibrate, size inner diameter, choose capacity, and advise integration

Donut Through-Hole Load Cell LTH 400 Versions

Item | Load Capacity | Inner Diametre cm | Outer Diametre cm | Height cm | Length cm | Width cm | Connection Type |

FSH04179 | 44482.2 N | 0.9525 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

| FSH04180 | 44482.2 N | 1.27 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

FSH04181 | 44482.2 N | 1.59 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

| QSH01074 | 1112.06 N | 1.59 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

QSH01388 | 44482.2 N | 0.9525 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

| QSH01688 | 44482.2 N | 1.59 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

QSH01798 | 1556.88 N | 1.59 cm | 5.03 cm | 1.60 cm | 5.03 cm | 5.03 cm | Cable |

Ordering & Configuration Notes

If you would like more information about this product, or would like to place an order, please contact us.

When selecting an LTH400, consider:

Inner Diameter (I.D.) – Choose the bore size (3/8″, ½”, 5/8″, etc.) to suit your bolt or shaft.

Capacity – Pick a load rating that exceeds your maximum expected load by margin.

Cable vs Connector – Connector version (micro circular) enables easier disconnection; cable version may also be available.

Calibration – Request standard 5-point compression calibration or optional custom calibration.

Mounting & alignment – Ensure the sensor is flush-mounted, aligned coaxially, and avoid side/bending loads.