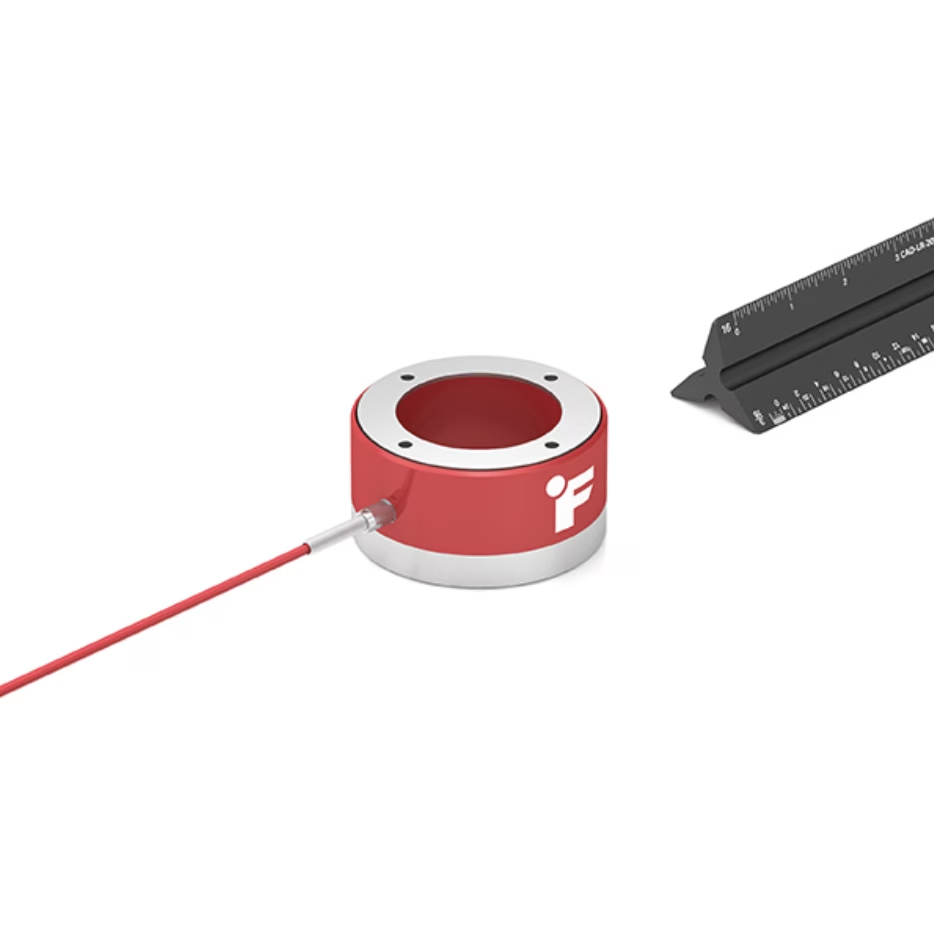

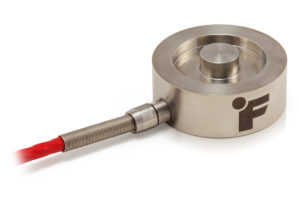

This force washer load cell is made from 17-4 stainless steel with an anodised aluminium cover. It features a 2.98″ outer diameter and uses metal foil strain gauge technology for high accuracy force measurement. It also has a minimal deflection of approximately 0.001″ and an operating temperature range from -50 °C to ~100 °C. As a result, the LLW555 delivers reliable, high stiffness measurement in harsh environments.

⚙️ Key Features

Robust construction: 17-4 stainless steel body with an anodised aluminium cover.

Compact “washer” (through hole) design with a 2.98″ (≈ 75.7 mm) outer diameter.

Central mounting hole diameter of 1.75″ (44.5 mm).

Designed for compression (press or inline) applications.

Nominal deflection of only ~0.001″ (high stiffness).

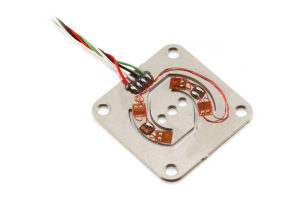

Metal foil strain gauge technology (for high accuracy).

Operating temperature range from approximately –60 °F to +212 °F (≈ –50 °C to +100 °C).

Supplied with 5 ft (≈1.5 m) 26 AWG 4 conductor spiral shielded Teflon cable.

🚀 Applications

Monitoring bolt tension and clamping forces in mechanical assemblies

Press-fit operations and compression testing

Structural load monitoring in industrial gear

Fastening and torque verification systems

Integration into automated manufacturing and production equipment

Use in research, engineering, and test rigs that need high stiffness force measurement

Suitable for aerospace, defence, automotive, and heavy industrial environments where stregth and accuracy are critical

FAQs

1. What does the LLW555 measure?

The LLW555 measure compression force in applications such as bolt tension monitoring, clamping force verification, press fit operations, and structural load testing.

2. Can the LLW555 handle dynamic loads?

Yes. Its high stiffness and minimal deflection (~0.001″) make it perfect for both static and certain dynamic compression applications within its rated capacity.

3. What type of output signal does it provide?

It uses metal foil strain gauge technology and outputs a standard mV/V signal. As a results, it’s compatible with most industrial amplifiers, indicators, and data acquisition systems.

4. Can it be used outdoors or in harsh environments?

Yes. Its stainless steel construction and sealed design make it perfect for harsh industrial, defence, and aerospace environments, Yet, it’s important to note that it must be paired with appropriate environmental protection.

5. Is the LLW555 customisable?

Yes. FUTEK offers custom options for capacity, mounting, and cable to suit various applications.

6. Does it require calibration?

All FUTEK sensors are shipped factory calibrated, yet occasional recalibration is suggested.

To explore a full overview of FUTEK’s Load Cell range and technical features.