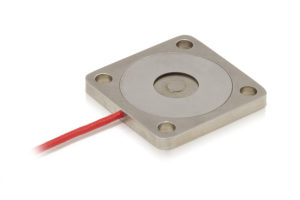

The integrated slip-ring design of the Rotary Torque Sensor TRS150 enables continuous torque measurement from stall through rotation. As a result, it’s ideal for miniaturised test rigs, robotics, medical devices, and other demanding applications where a compact Rotary Torque Sensor is essential. This sensors is also manufactured with aerospace-grade stainless steel and anodised aluminium housing. Finally, the TRS150 also combines rugged durability with exceptional sensitivity. As a resultm it’s ready to integrate into your next advanced instrumentation or OEM solution.

Key Features of the TRS150 Smallest Rotary Torque Sensor

- Ultra-compact size: 17 mm × 17 mm cross-section and only ~53 mm in length, enabling integration into very tight assemblies.

- Lightweight design: approx 1 oz (28 g), ideal where mass is critical.

- Slip-ring signal transfer: integrated slip ring allows continuous torque measurement on a rotating shaft from stall through rotation.

- High accuracy and repeatability: non-linearity ±0.1% RO, hysteresis ±0.2% RO, non‐repeatability ±0.05% RO.

- Safe overload rated to 150% of rated output.

- Low power consumption: designed for low-voltage excitation (≤ 10 VDC) making it suitable for portable or embedded systems.

- Compact shaft-to-shaft mounting: available with small diameter shafts (5 mm / 6 mm) for torque capacities from 0.5 N·m up to 2 N·m.

- Robust mechanical construction: stainless steel shaft and anodised aluminium housing.

Applications of the TRS150 Smallest Rotary Torque Sensor

- Precision torque measurement in miniaturised test rigs and benchtop systems

- Robotics and automation where compact, lightweight torque sensing is required

- Medical devices and surgical tool testing requiring high accuracy in limited space

- Motor and actuator performance testing for small electric or servo motors

- Aerospace and defence applications where low-mass, high-sensitivity components are critical

- R&D laboratories for prototype testing and material torque characterisation

- Quality control and calibration systems for small torque tools or components

- OEM integration into portable or embedded torque measurement systems

FAQs About the TRS150 Smallest Rotary Torque Sensor

1. What makes the TRS150 different from other rotary torque sensors?

The TRS150 is one of the smallest rotary torque sensors available, featuring a compact 17mm × 17mm housing and lightweight 28g design—ideal for applications where space and mass are critical, such as robotics and medical devices.

2. How does the TRS150 measure torque while rotating?

It uses a precision slip-ring and brush system that transfers the strain-gauge signal from the rotating shaft to the stationary electronics, allowing continuous torque measurement during rotation.

3. What torque capacities are available for the TRS150?

The TRS150 is available in ranges from 0.5 N·m to 2 N·m, covering low-torque applications such as small motor testing, lab instruments, and precision assemblies.

4. Is the TRS150 compatible with Metromatics’ data acquisition systems?

Yes. The TRS150 outputs a standard mV/V strain-gauge signal, making it fully compatible with Metromatics’ range of amplifiers, DAQ systems, and signal conditioners for seamless integration.

Learn More about the TRS150 Smallest Rotary Torque Sensor

If you have any other questions or would like to learn more about this product, please contact us.