Key Features & Benefits

3-Axis Force Measurement in One Sensor — measure forces in Fx, Fy, and Fz concurrently without needing multiple separate sensors.

Low Crosstalk — engineered to minimize interference between axes, improving measurement purity.

Good Overload Protection — safe overload up to 150% of rated output (RO) to protect the sensor under transient loads.

Rugged Construction & Aluminum Body — lightweight yet durable design for many engineering and test environments.

Connectorized Interface — 10-pin LEMO® receptacle (EGG.1B.310.CLL) for clean, reliable connections.

Wide Temperature & Environmental Range — operates from –60 °F to +200 °F (–51 to +93 °C), with compensated temperature range of 60-160 °F.

Ideal for Advanced Applications — perfect for wind tunnel force studies, flight control validation, robotic actuator reaction forces, and multi-axis instrumentation setups.

Technical Specifications

| Specification | Detail |

|---|---|

| Capacity | Fx & Fy: 250 lb each; Fz: 500 lb |

| Nonlinearity | ±0.25 % of RO |

| Hysteresis | ±0.25 % of RO |

| Cross Talk | ≤ ±3 % of RO (among axes) |

| Rated Output | Fx, Fy: ~1.5 mV/V nominal; Fz: ~0.75 mV/V nominal |

| Excitation (max) | 18 VDC or VAC |

| Input Bridge Resistance | ~253 Ω (nominal) |

| Output Bridge Resistance | ~700 Ω (nominal) |

| Insulation Resistance | ≥ 500 MΩ @ 50 VDC |

| Safe Overload | 150 % of RO |

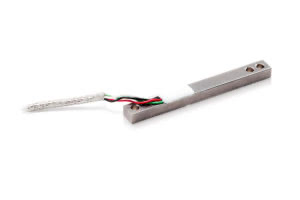

| Material / Construction | Aluminium flexure with red anodized covers |

| IP Rating | IP40 (standard) |

| Operating Temperature | –60 to +200 °F (–51 to +93 °C) |

| Compensated Temperature | 60 to 160 °F (15 to 72 °C) |

| Zero / Span Temperature Shifts | ~±0.01 % RO / °F and ±0.01 % of load / °F |

| Weight | ~2 lb (≈ 907 g) |

Typical Applications

Wind tunnel testing — lift, drag, and side force measurement

Aircraft flight control validation and instrumentation

Robotic actuator reaction force measurement

Multi-axis load monitoring in test stands or structural systems

Aerospace, Defence, automotive, and advanced research systems

Why Choose the MTA400 via Metromatics

Compact Multi-Axis Solution — integrates three force measurements in one sensor, saving space and reducing system complexity

Low Crosstalk & Accurate Output — ensures force components are well isolated and dependable

Robust Overload Safety & Durable Design — protects against accidental overloads, mechanical stress, and harsh conditions

Connector & Configuration Flexibility — standard LEMO connector for robust system interfacing

Support & Calibration Services — Metromatics can provide calibration, custom wiring, mounting advice, and verification to match your application

Ordering & Configuration Tips

If you would like to learn more information about this product, please contact us.

When specifying an MTA400, consider:

Your required force ranges in all three axes (Fx, Fy, Fz) to ensure you choose the correct variant

Mounting / fixture design to minimize off-axis loads and loading errors

Cable / connector routing and shielding considerations for EMI, noise, and signal integrity

Calibration needs (tension/compression, matching across axes, traceable certificates)

Environmental or temperature extremes — check sealing, thermal drift, and mechanical protection

Tri-Axial Load Cell MTA400

Item | Load Capacity | Mounting Type | Length in cm | Height in cm | Width in cm | Output type | # of Axis |

| 2224.11 N | Flange | 7.49 cm | 7.62 cm | 7.49 cm | Mv/V | 3 |

Finally, the MTA400 are a Triaxial Load Cell Series. Download the FUTEK MTA400 datasheet (PDF) to view technical specifications and configuration options.