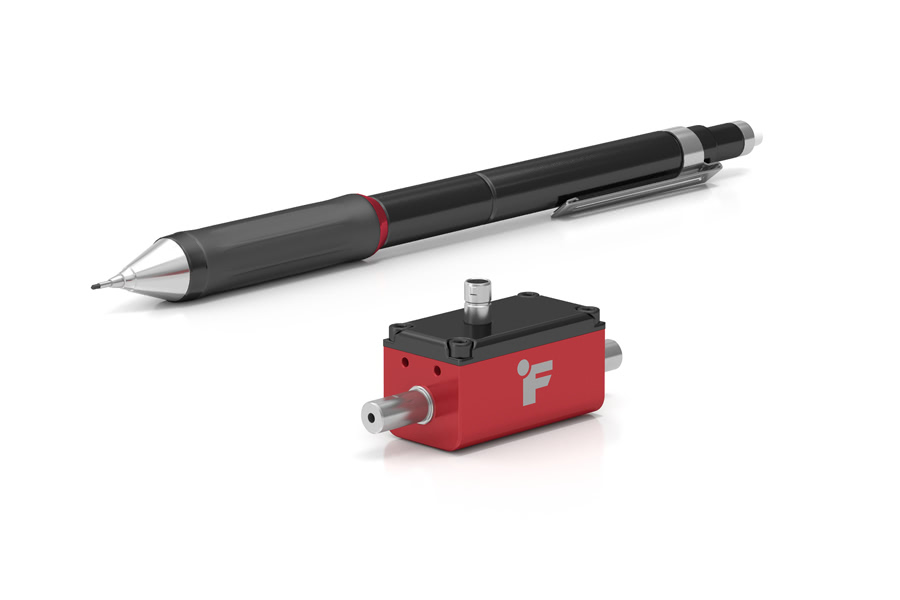

FUTEK has released the QTA163, a custom-built miniature torque sensor that weighs a mere 28.3 grams! With a 5mm shaft it is capable of measuring torque of up to 150 RPMs at a capacity of 8.851 in-lb.

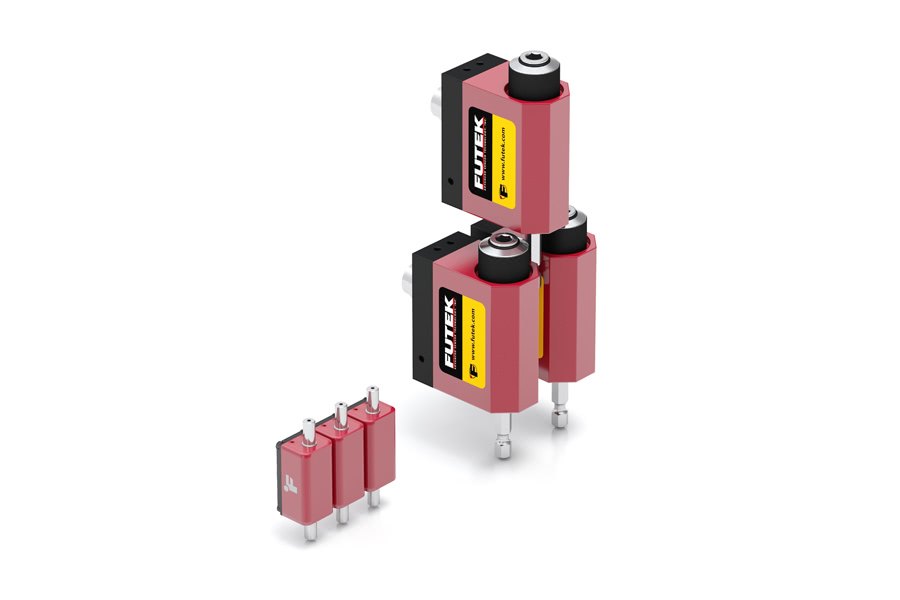

Firstly, housed in 17-4 stainless steel housing. This ensures durability and reliability over a wide temperature range. This compact design, with a cross width of 17mm x 17mm enables integration into systems and devices where space is at a premium. Therefore, this smaller cross section allows multiple sensors in an array within a narrow space. Compared to the stacking of larger torque sensors.

The custom-built internal slip ring allows the electrical signal to transfer from a rotating component to the stationary stator (outside the housing). Whilst still providing accurate reading and reliability. Another point of difference is the low power consumption considering the 1000-ohm bridge.

Secondly, the built in TEDS chip provides additional information on the internals of the sensor. Set up time is reduced. Simply by factory calibrating your sensor with your choice of amplifier before it leaves the FUTEK Manufacturing facilities.

This product is suitable for a wide range of torque applications. Such as in surgical robots, dental drills, precision machining and assembly operations. Also, in directional control units in cube satellites, machining of composites, rheometers in pharmaceutical and chemical plants and much more.

To learn more click here or contact us.