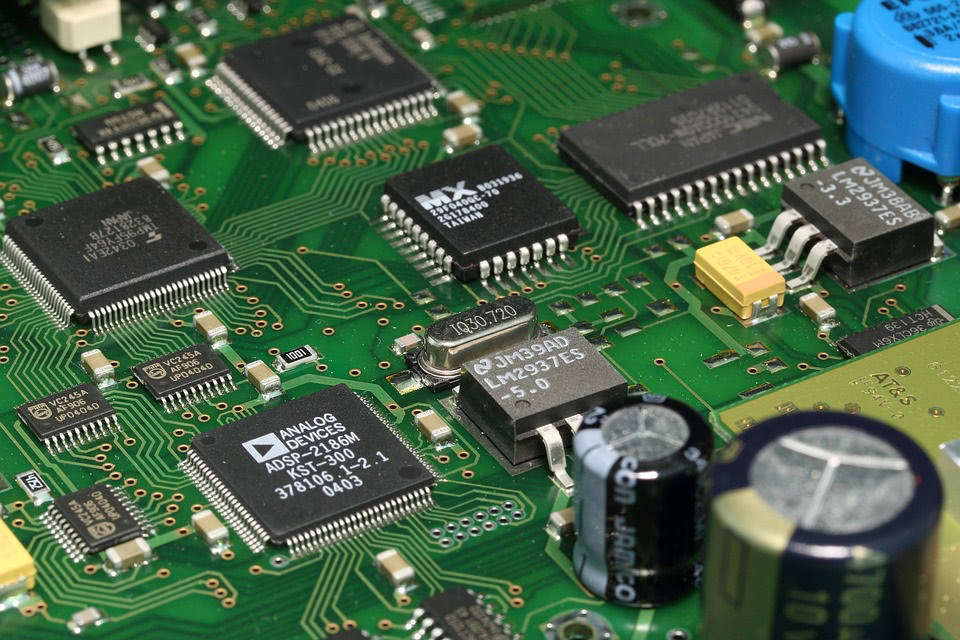

Printed Circuit Board Repair Systems

For over 40 years, Huntron Test Equipment has helped countless customers with reverse engineering, troubleshooting, fault finding, and repairing their printed circuit board assemblies.

Huntron manufacture Circuit Board Fault Finding and Automated Flying Probe Testing Systems

Their wide range of circuit board fault finding and flying probe testing tools are used by a variety of organisations world-wide. They assist in the increase operator productivity, provide accurate measurements, and troubleshoot expensive circuit board assemblies cost-effectively.

Do you need a Printed Circuit Board Repair System that is user friendly and easy to operate?

One of the great things about Huntron’s products is that they are designed to be user-friendly and easy to operate. This means that even if you’re not an expert in electronics, you can still use their equipment effectively. And with accurate and repeatable measurements, you can trust that you’re getting reliable results every time.

How about an Automated Test System for your Electronics Production line that integrates with conventional Test Equipment?

One standout feature of Huntron’s Robotic Flying Probe Systems, also known as Huntron Access Prober Products, is that they can be configured to work with conventional test instruments like oscilloscopes, DMMs, and spectrum analysers. This makes them a complete automated test equipment system, offering a comprehensive solution for your testing needs.

Overall, Huntron Instruments is a great choice for anyone looking for reliable and easy-to-use electronic test equipment. With their wide range of products, Huntron Instruments is sure to be a valuable addition to your toolkit.

Read on about recent Huntron Product Purchases and their uses:

European Communications Company

Firstly, a European Communications company, who is in the process of establishing a 5G mobile network. Recently purchased a Tracker 3200S, Huntron Access and CAD. These tools will be used to diagnose and troubleshoot the fallout from their production lines. They will be able to test the failed circuit boards PCB to a component level and replace failed circuitry as required.

Sustainability Engineering Department

Secondly, the sustainability engineering department of a major multinational technology company. Have developed a method using the Huntron Access Prober, Tracker 3200S and a Digital Multi Meter to determine product component failure lifecycles. In addition, this enables them to advise design failure trends to their product development group allowing the build of more reliable products.

Military Training Organisation

Thirdly, supplying Military Training objectives globally using their large fleet of ex-military aircraft. This organisation has created a new standard. A range of aviation service capabilities for the US Military and allied Defence Forces. They use the Huntron Access DH2 which is providing them a platform for diagnosing and repairing avionic and aircraft circuit card failures.

Specialist Communications Technology Company

Fourthly, a relatively new specialist communications technology company has invested in a Huntron Access 2 and Digital Multi meter to verify that prototype arrays meet the required communications specification.

Defence Worldwide

Finally, Defence worldwide have always been a great user of Huntron Test Equipment. Uses include the ability to diagnose faults and make repairs to printed circuit boards. This is critically important for communications and warfare equipment, when in deployment.

However, a recent purchase of a Huntron Access DH by a Defence Prime has a different purpose. That is to help re-engineer the printed circuit boards of a proven legacy system. The old printed circuit board assemblies are no longer in production and drawings were unable to be provided. Therefore, they had to work backwards first of all determining the component level.

Quality Assurance Department of Australian Elevator and Escalator Manufacturer

The Australian division of this global manufacturer of Elevators and Escalators invested in a Tracker 3200S. With the purpose to integrate with their testing processes as part of their Quality Assurance department. It enables them to spot check PCB boards, identify any faults with batches, make circuit board repairs before processing any further.

Want to know more?

Finally, this is just a small selection of recent purchases and their uses of Huntron Test Equipment. Maybe, one of these applications you’re able to relate to. If you’re in Australia or New Zealand, and this article has got you thinking and you can see how a Huntron System would solve a problem or benefit your business. Need to know more? Give us (Metromatics) a call or drop us a line. Let us walk you through the Huntron Product range. Providing you with an amazing, reliable test system.